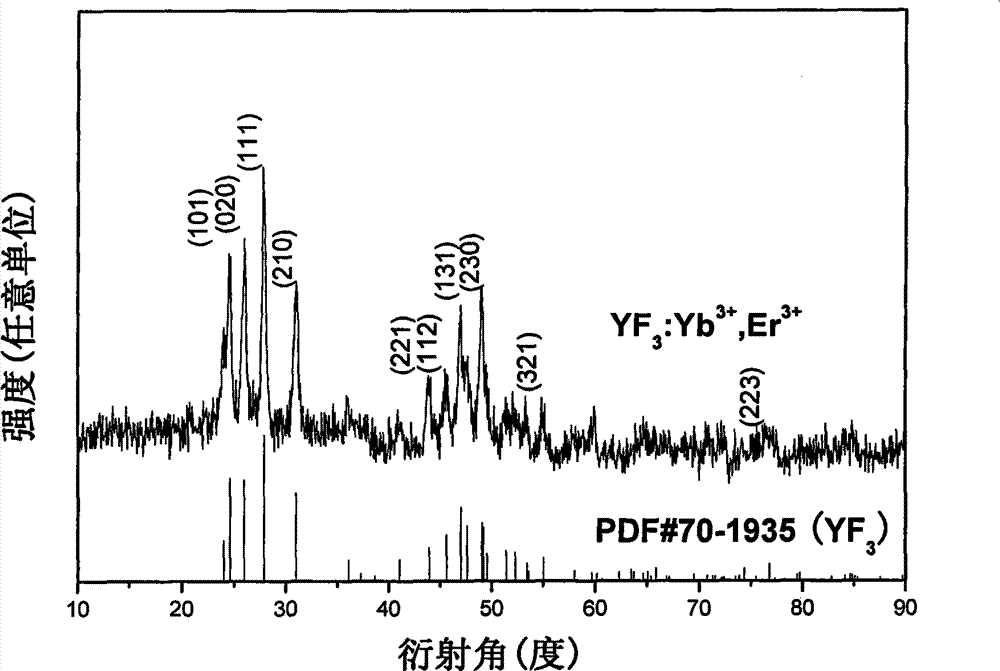

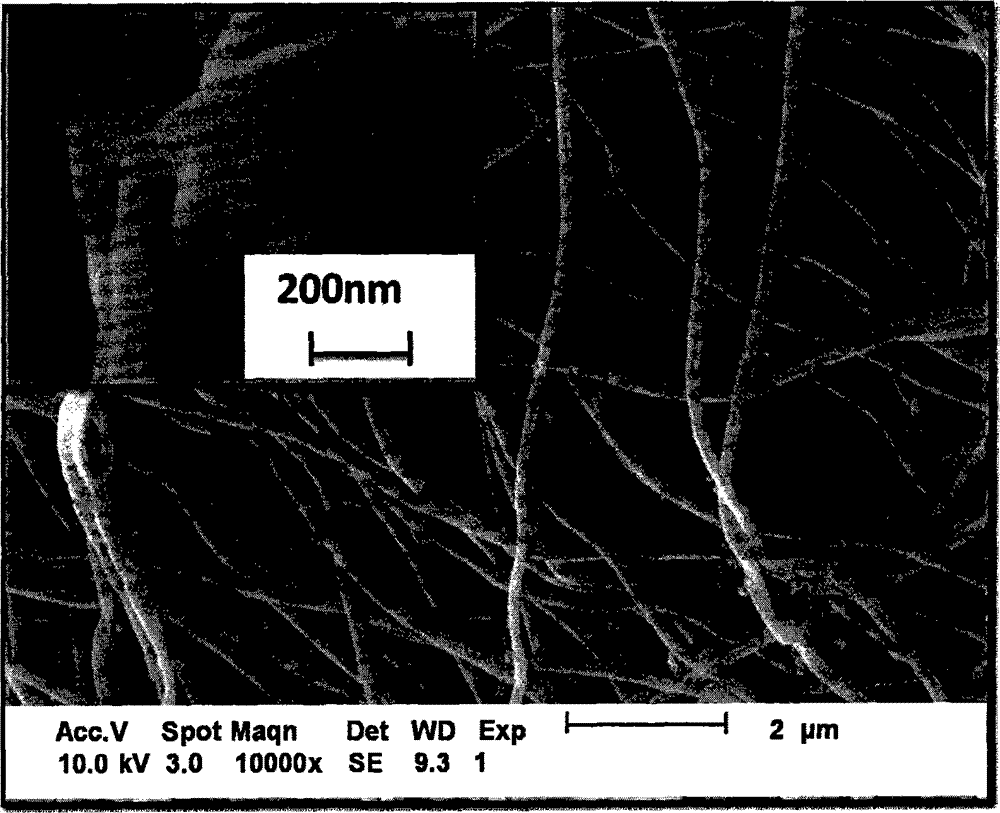

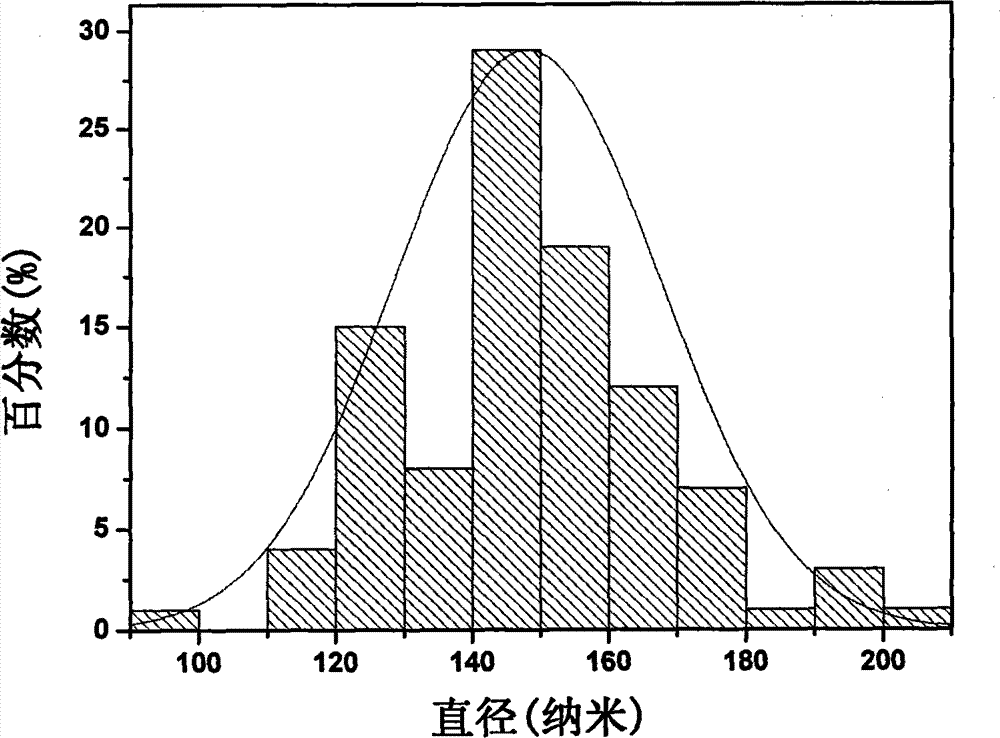

Method for preparing Er-Yb co-blended yttrium fluoride up-conversion luminescence hollow nanofibers

A hollow nano, yttrium trifluoride technology, applied in chemical instruments and methods, luminescent materials, fiber chemical characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The selected yttrium oxide Y of the present invention 2 o 3 , erbium oxide Er 2 o 3 and ytterbium oxide Yb 2 o 3 The purity is 99.99%, polyvinylpyrrolidone PVP, molecular weight 10000, N,N-dimethylformamide DMF, carbon rod, ammonium bifluoride NH 4 HF 2 and nitrate HNO 3 All are commercially available analytically pure products; the glass instruments, crucibles and equipment used are commonly used instruments and equipment in laboratories. Embodiment: take a certain amount of yttrium oxide Y 2 o 3 , erbium oxide Er 2 o 3 and ytterbium oxide Yb 2 o 3 , where Y 3+ 、Er 3+ and Yb 3+ The molar ratio is 79:1:20, that is, doped erbium ions Er 3+ and ytterbium ion Yb 3+ The mole percentages are 1% and 20%, respectively, with HNO 3 Dissolved and evaporated to give Y(NO 3 ) 3 , Er(NO 3 ) 3 and Yb(NO 3 ) 3 Mix the crystals, add DMF and PVP, stir magnetically at room temperature for 4 hours, and let stand for 2 hours to form a spinning solution. The mass per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com