Method and apparatus for evaluating cellulose pulp reaction performance

A technology of cellulose pulp and reaction performance, applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve problems such as errors, complicated procedures, and long processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

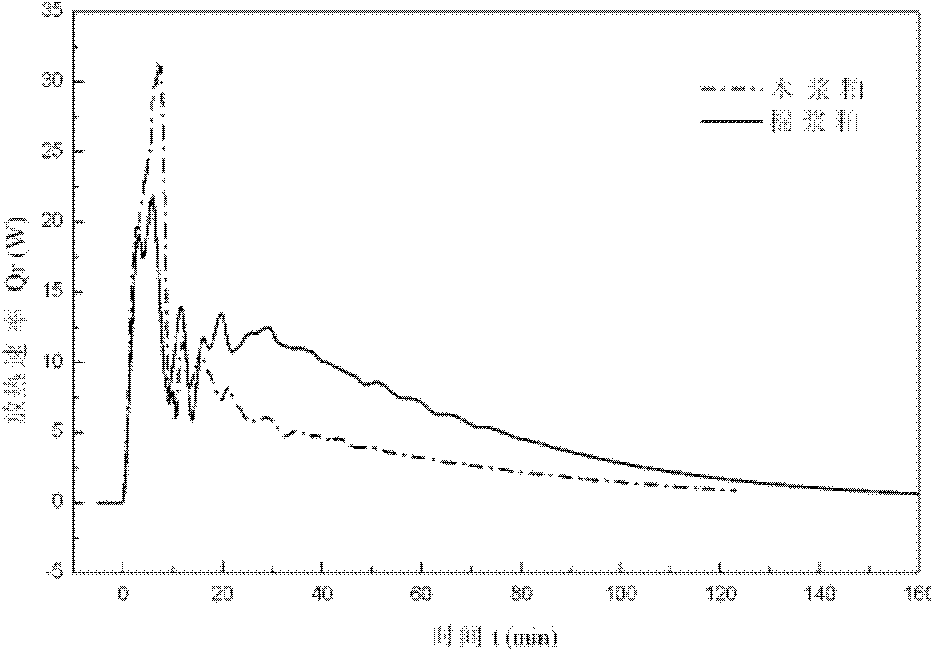

Embodiment 1

[0100] (1) Add 160g of acetic anhydride, 240g of acetic acid and 12g of sulfuric acid into the reaction kettle (cylindrical, 1L volume), the volume reaches 2 / 3~3 / 4 of the volume of the reaction kettle, and the mass ratio of acetic anhydride, acetic acid and sulfuric acid is 1: 1.5∶0.075;

[0101] (2) Set the reaction temperature T r 30°C, and control the material in the reactor and the jacket medium to reach the reaction temperature T r ,T r =T j ,T j is the jacket temperature;

[0102] (3) start stirring, stirring rate 100rpm, measure the specific heat and heat transfer coefficient of reaction material under this temperature;

[0103] (4) Grinding pulp (wood pulp), the average diameter of the pulp after grinding is about 0.5 cm. 30 g of pulp was fed into the reactor at a constant speed at a constant rate, and the mass ratio of pulp: acetic anhydride was 0.1875:1. Start the reaction while measuring T r , T j , viscosity and turbidity;

[0104] (5) Using a viscosity m...

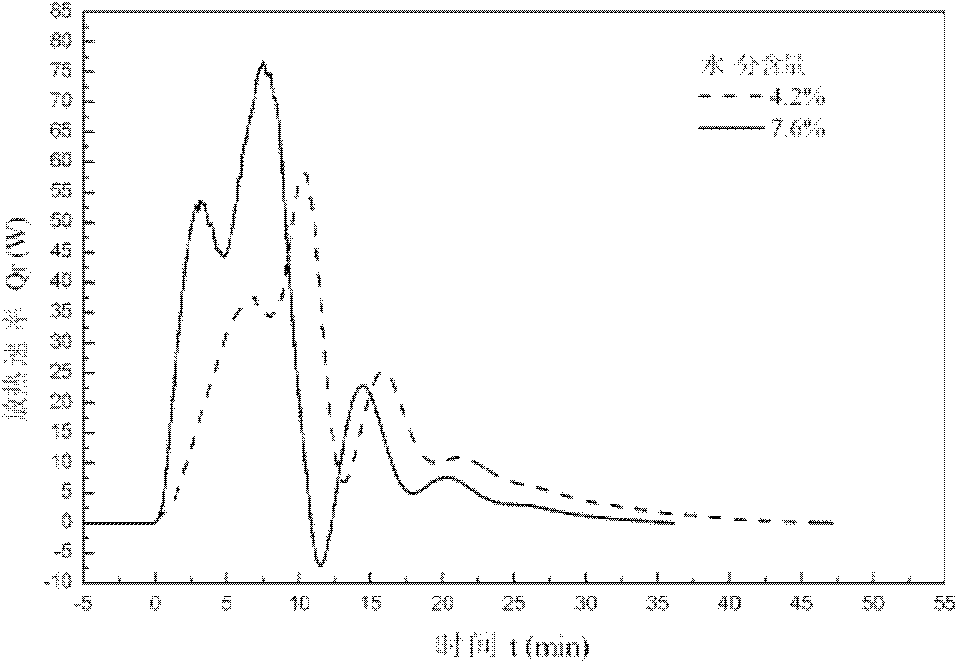

Embodiment 2

[0115] (1) Add 260g of acetic anhydride, 320g of acetic acid and 20g of sulfuric acid into the reactor, the volume reaches 2 / 3~3 / 4 of the volume of the reactor, and the mass ratio of acetic anhydride, acetic acid and sulfuric acid is 1: 1.23: 0.076;

[0116] (2) Set the reaction temperature T r 50°C, and control the material in the reactor and the jacket medium to reach the reaction temperature T r ,T r =T j ,T j is the jacket temperature;

[0117] (3) measure the specific heat and heat transfer coefficient of reaction material under this temperature;

[0118] (4) Ground pulp (hardwood pulp), the average diameter of the ground pulp is about 0.5 cm. Place one part of wood pulp under natural conditions in a room temperature room; the other part of wood pulp is dried at 90°C for 30 minutes;

[0119] (5) 50 g of naturally placed wood pulp was fed into the reactor at a constant rate at a constant rate, and the mass ratio of pulp: acetic anhydride was 0.1923:1. Start the reac...

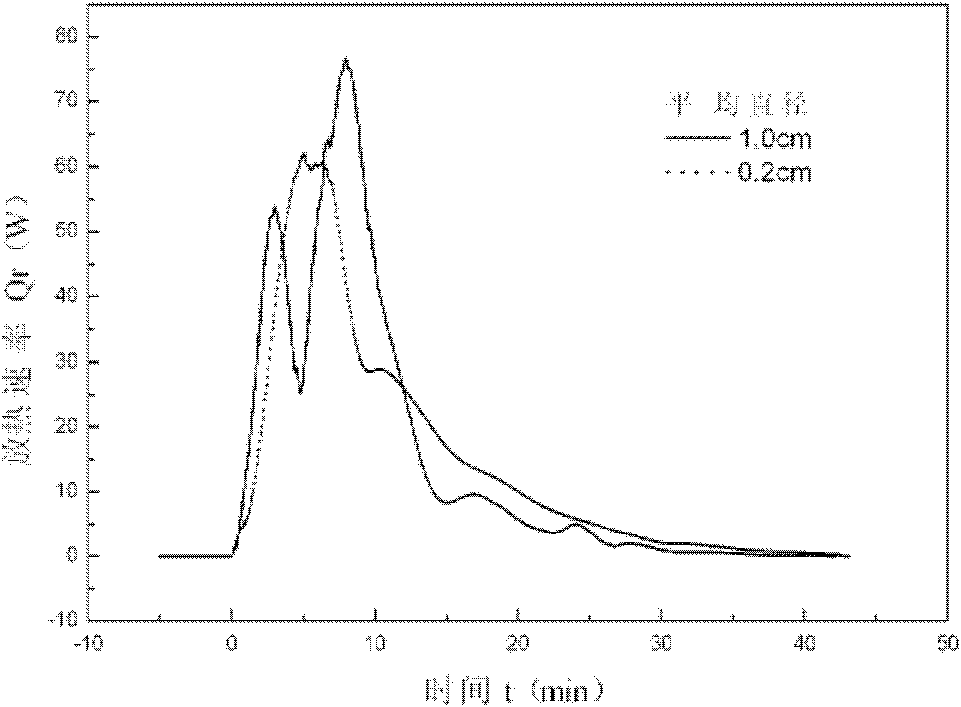

Embodiment 3

[0132] (1) Add 200 g of acetic anhydride, 300 g of acetic acid and 15 g of sulfuric acid into the reactor, the volume reaches 2 / 3 to 3 / 4 of the volume of the reactor, and the mass ratio of acetic anhydride, acetic acid and sulfuric acid is 1: 1.5: 0.075;

[0133] (2) Set the reaction temperature T r 50°C, and control the material in the reactor and the jacket medium to reach the reaction temperature T r ,T r =T j ,T j is the jacket temperature;

[0134] (3) measure the specific heat and heat transfer coefficient of reaction material under this temperature;

[0135] (4) Two parts of ground wood pulp: the grinding parameters are different, and the average diameter of the pulp after grinding is about 1 cm and 0.2 cm respectively;

[0136] (5) Add 40 g of wood pulp with an average diameter of about 1 cm into the reactor at a constant feed rate, and the mass ratio of pulp: acetic anhydride is 0.2:1. Start the reaction while measuring T r , T j , viscosity and turbidity;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com