A method and device for evaluating the reaction performance of cellulose pulp

A technology of cellulose pulp and reaction performance, which is applied in the direction of measuring devices, flow characteristics, instruments, etc., and can solve problems such as complicated procedures, long processes, and errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] (1) Add 160g of acetic anhydride, 240g of acetic acid and 12g of sulfuric acid into the reaction kettle (cylindrical, 1L volume), the volume reaches 2 / 3~3 / 4 of the volume of the reaction kettle, and the mass ratio of acetic anhydride, acetic acid and sulfuric acid is 1: 1.5∶0.075;

[0101] (2) Set the reaction temperature T r 30°C, and control the material in the reactor and the jacket medium to reach the reaction temperature T r ,T r =T j ,T j is the jacket temperature;

[0102] (3) start stirring, stirring rate 100rpm, measure the specific heat and heat transfer coefficient of reaction material under this temperature;

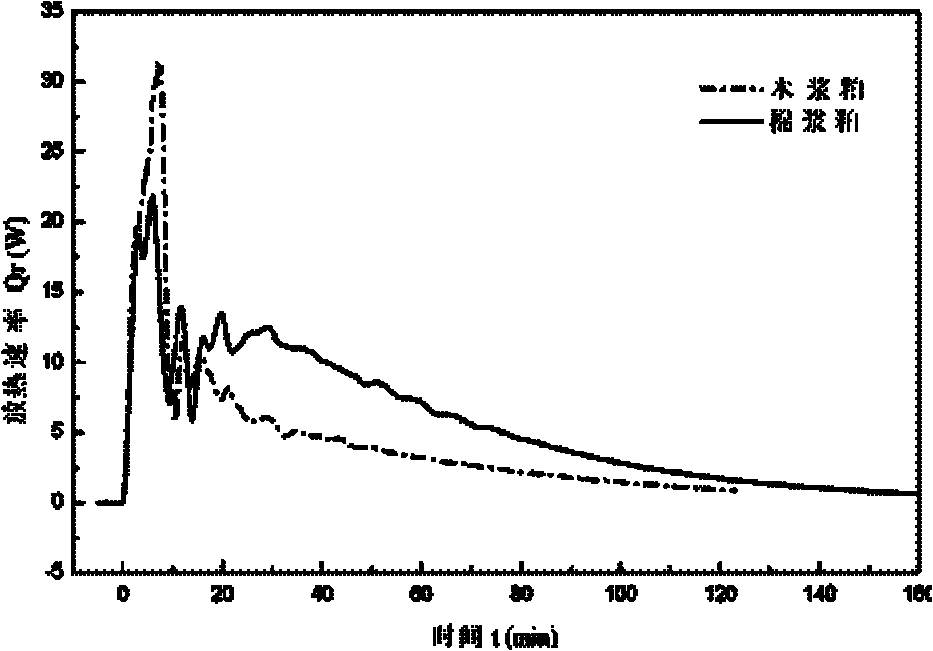

[0103] (4) Grinding pulp (wood pulp), the average diameter of the pulp after grinding is about 0.5 cm. 30 g of pulp was fed into the reactor at a constant speed at a constant rate, and the mass ratio of pulp: acetic anhydride was 0.1875:1. Start the reaction while measuring T r , T j , viscosity and turbidity;

[0104] (5) Using a viscosity m...

Embodiment 2

[0115] (1) Add 260g of acetic anhydride, 320g of acetic acid and 20g of sulfuric acid into the reactor, the volume reaches 2 / 3~3 / 4 of the volume of the reactor, and the mass ratio of acetic anhydride, acetic acid and sulfuric acid is 1: 1.23: 0.076;

[0116] (2) Set the reaction temperature T r 50°C, and control the material in the reactor and the jacket medium to reach the reaction temperature T r ,T r =T j ,T j is the jacket temperature;

[0117] (3) measure the specific heat and heat transfer coefficient of reaction material under this temperature;

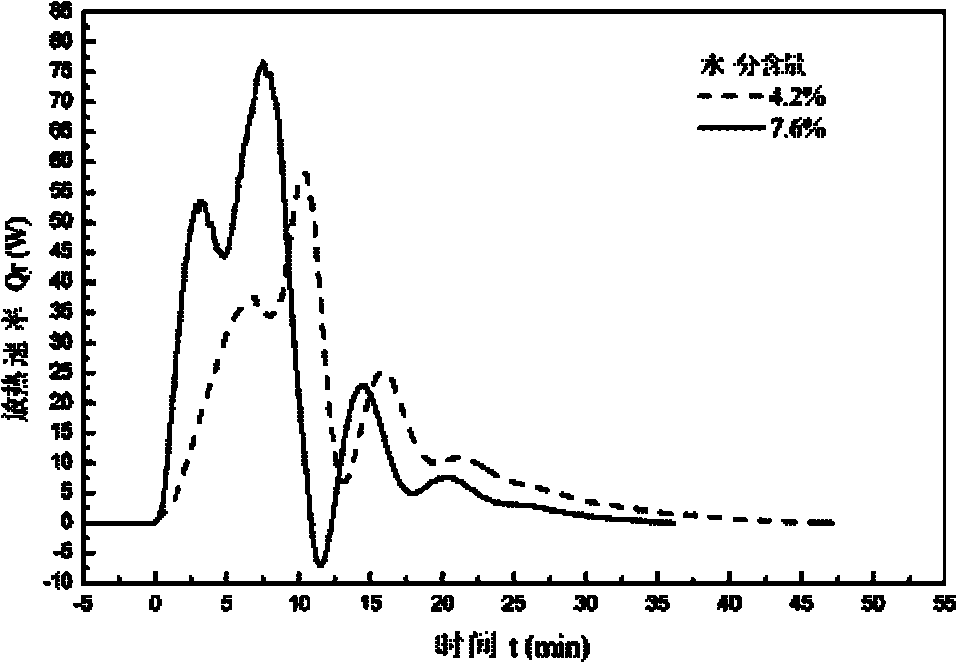

[0118] (4) Ground pulp (hardwood pulp), the average diameter of the ground pulp is about 0.5 cm. Place one part of wood pulp under natural conditions in a room temperature room; the other part of wood pulp is dried at 90°C for 30 minutes;

[0119] (5) 50 g of naturally placed wood pulp was fed into the reactor at a constant rate at a constant rate, and the mass ratio of pulp: acetic anhydride was 0.1923:1. Start the reac...

Embodiment 3

[0132] (1) Add 200 g of acetic anhydride, 300 g of acetic acid and 15 g of sulfuric acid into the reactor, the volume reaches 2 / 3 to 3 / 4 of the volume of the reactor, and the mass ratio of acetic anhydride, acetic acid and sulfuric acid is 1: 1.5: 0.075;

[0133] (2) Set the reaction temperature T r 50°C, and control the material in the reactor and the jacket medium to reach the reaction temperature T r ,T r =T j ,T j is the jacket temperature;

[0134] (3) measure the specific heat and heat transfer coefficient of reaction material under this temperature;

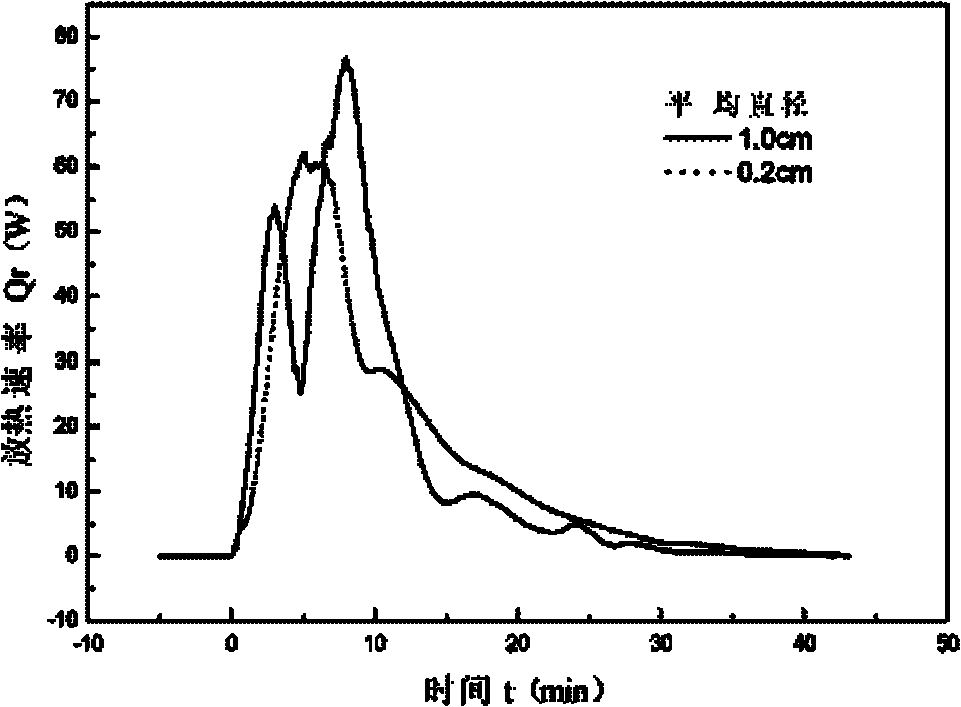

[0135] (4) Two parts of ground wood pulp: the grinding parameters are different, and the average diameter of the pulp after grinding is about 1 cm and 0.2 cm respectively;

[0136] (5) Add 40 g of wood pulp with an average diameter of about 1 cm into the reactor at a constant feed rate, and the mass ratio of pulp: acetic anhydride is 0.2:1. Start the reaction while measuring T r , T j , viscosity and turbidity;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com