Polyester lithium ion battery diaphragm and preparation method

A lithium-ion battery, polyester film technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of inability to produce porous polyester film, complex manufacturing process, high production cost, and achieve high mechanical properties and The effect of dimensional stability, reasonable pore size and porosity, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

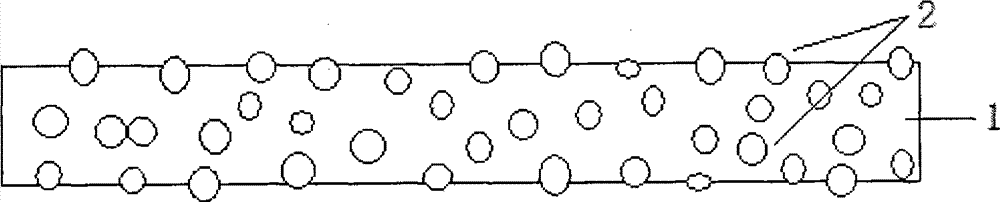

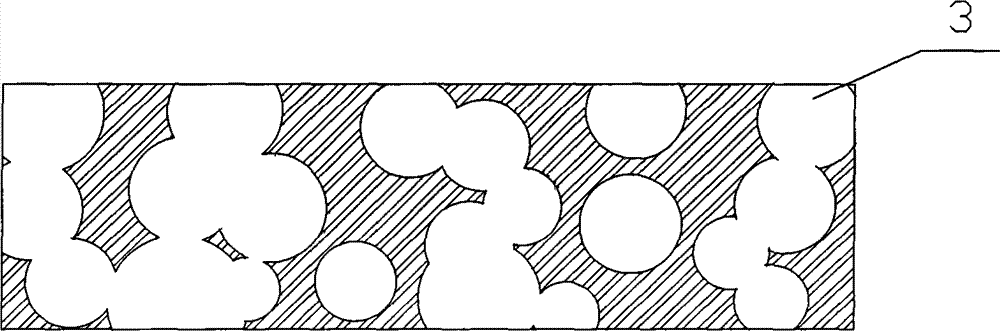

[0038] (2) Preparation of polyester base film containing inorganic filler particles

[0039] The above-mentioned polyester film substrate raw materials are prepared on a polyester film stretching production line produced by Mitsubishi Heavy Industries, Japan. The preparation steps of the base film are as follows: mix the calculated polyester raw material slices (polyester bright raw material slices) with the polyester masterbatch slices containing inorganic filler particles, melt and extrude the cast sheets after drying, and the obtained thick slices are in the Stretch 3-4 times in the longitudinal direction at 90-110°C, stretch 3-4 times in the transverse direction at 85-115°C, heat-set at 220-230°C, wind up after cooling, and finally make the thickness 4μm-32μm The polyester base film, the polyester base film referred to as the base film.

[0040] For the base film with a thickness of more than 32 μm, it is prepared by using a small static stretching machine in the laborato...

Embodiment 1

[0046] Prepare the base film and porous polyester film containing inorganic particles according to the aforementioned method, wherein SiO 2 The content in the whole base film is 40% by weight, and the thickness of the prepared film is 12 μm. The relevant properties of the obtained porous polyester film are shown in Table 1.

Embodiment 2

[0048] Prepare the base film and porous polyester film containing inorganic particles according to the aforementioned method, wherein SiO 2 The content in the entire base film is 60% by weight, and the thickness of the prepared film is 12 μm. The relevant properties of the obtained porous polyester film are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com