Method for extracting valerenic acid from valeriana fauriei

A technology of valerenic acid and valerian, applied in the field of biochemistry, can solve the problems of expensive equipment, rarely used, increased production costs, etc., to achieve the effects of improving production safety, increasing effective output, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

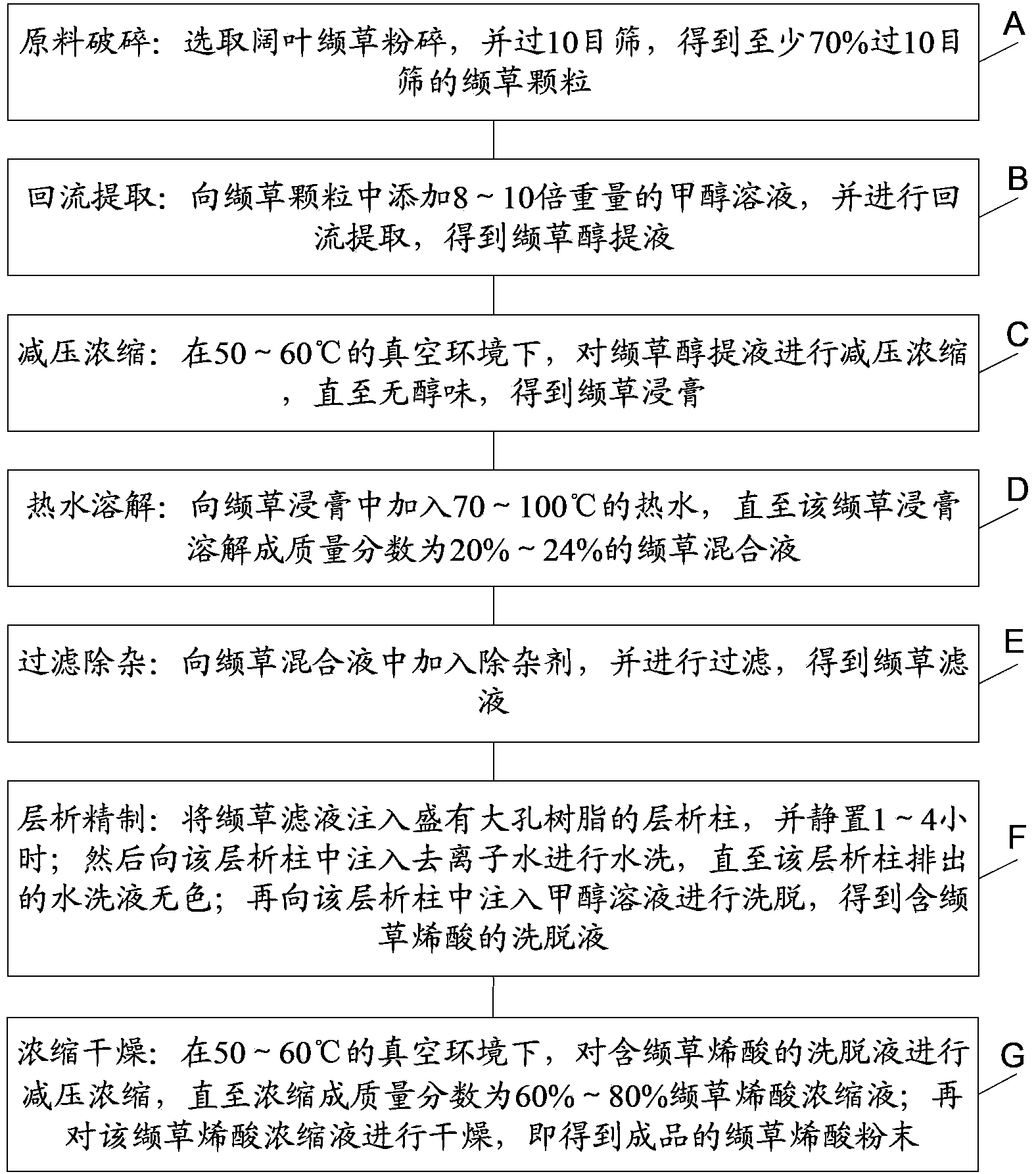

[0064] In this embodiment, weight is in kilograms (kg), and concentration is percentage by weight (%); figure 1 Shown, a kind of method extracting valerenic acid from Valerian officinale, its specific steps can comprise:

[0065] A, raw material crushing: choose 250kg of Valerian officinalis broadleaves to pulverize, and cross 10 mesh sieves, obtain at least 70% of Valerian officinale granules crossing 10 mesh sieves.

[0066] B, reflux extraction: add 2500kg of methanol solution to valerian granules, and reflux extraction at a heating temperature of 80 to 85°C for 2 hours, filter to obtain the first extracted filter residue and filtrate; add 2000kg of valerian to the first extracted filter residue Methanol solution, and reflux extraction at a heating temperature of 80-85°C for 1.5 hours, and filtered to obtain the filter residue and filtrate extracted again; the filtrates extracted twice were mixed together to obtain the valerian ethanol extract.

[0067] C. Concentration un...

Embodiment 2

[0074] In this embodiment, the weight is in kilograms (kg), and the concentration is weight percent (%); the difference between this embodiment and embodiment one is that the component content of the macroporous resin has been adjusted; the macroporous resin in this embodiment The porous resin is prepared by mixing the following raw materials in parts by weight: 20 parts of activated carbon, 30 parts of aluminum oxide and 50 parts of polyamide.

[0075] Under the situation that other processes are all the same as in Example 1, finally obtain the valerenic acid powder of 0.9075kg finished product.

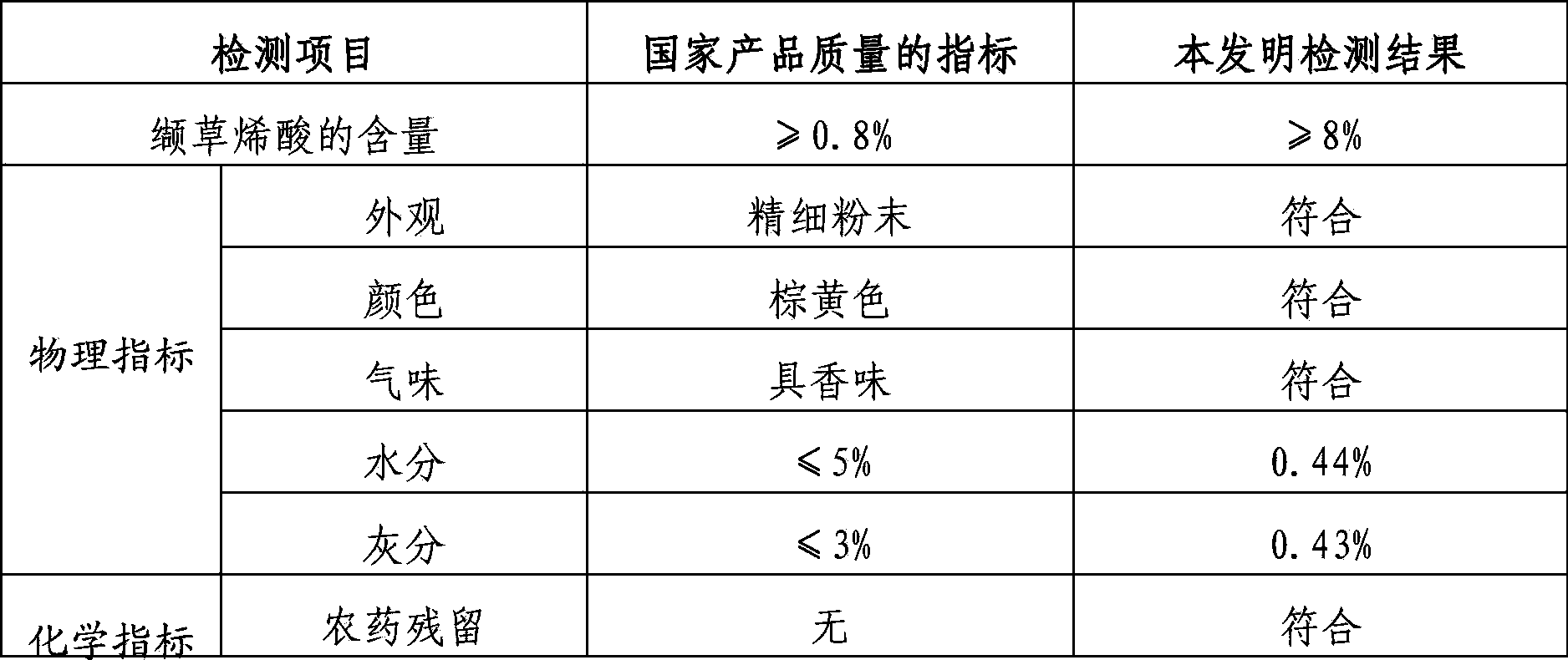

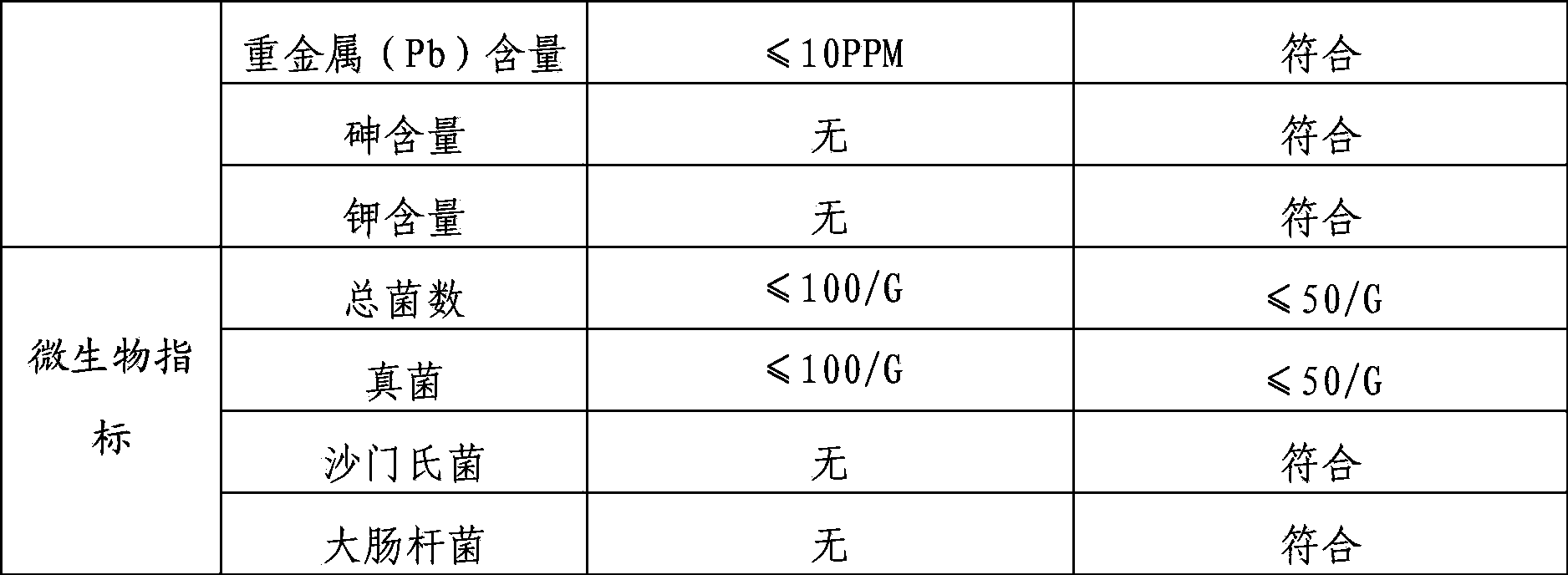

[0076] After testing, the content of valerenic acid in the finally obtained valerenic acid powder was more than 8%, and the yield was 0.363%. It can be seen that the method for extracting valerenic acid from Valerian officinalis provided by the embodiments of the present invention improves the effective yield of valerenic acid from Valerian officinalis and improves the purity of val...

Embodiment 3

[0078] In this embodiment, the weight is in kilograms (kg), and the concentration is weight percent (%); the difference between this embodiment and embodiment one is that the component content of the macroporous resin has been adjusted; the macroporous resin in this embodiment The porous resin is prepared by mixing the following raw materials in parts by weight: 10 parts of activated carbon, 20 parts of aluminum oxide and 70 parts of polyamide.

[0079] Under the situation that other processes are all the same as in Example 1, finally obtain the valerenic acid powder of 0.9301kg finished product.

[0080] After testing, the content of valerenic acid in the finally obtained valerenic acid powder was more than 8%, and the yield was 0.372%. It can be seen that the method for extracting valerenic acid from Valerian officinalis provided by the embodiments of the present invention improves the effective yield of valerenic acid from Valerian officinalis and improves the purity of val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com