A kind of preparation method of phenylvinyl methyl MQ silicone resin for high folding LED encapsulation

A technology of phenylvinylmethyl and LED encapsulation, which is applied in the field of organosilicon polymer compounds, and can solve the problems of decreased light transmittance, yellowing of resin, and large internal stress of curing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

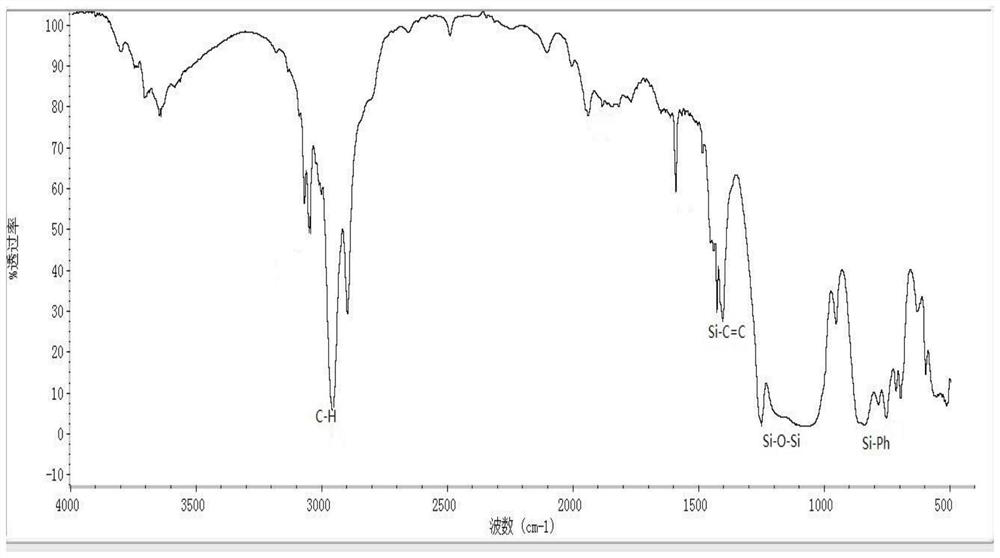

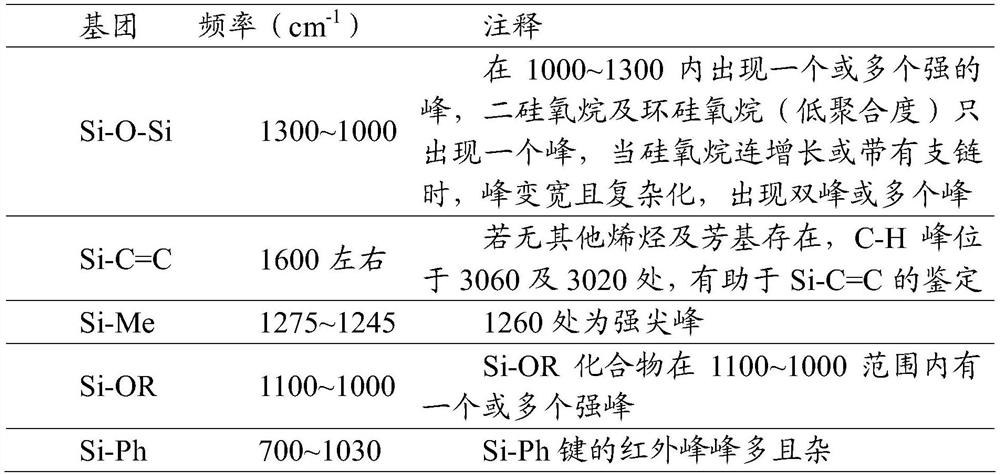

Image

Examples

Embodiment 1

[0018] Add 170 g of ethyl silicate, 111 g of hexamethyldisiloxane, 12 g of vinyl double caps, and 10 g of phenyl double caps in the three-necked flask, and mix well. At a reaction temperature of 10°C, 4 g of concentrated sulfuric acid and 30 g of water were slowly added dropwise. After 1 h of reaction, the temperature was raised to reflux for 4 h, and 40 wt % KOH solution was added dropwise to adjust the system to be neutral. Then distilled with toluene and filtered to obtain a clear and transparent silicone resin toluene solution. The toluene solvent was distilled off to obtain 270 g of a clear and transparent silicone resin with a phenyl vinyl network structure, with a yield of 89% and a vinyl content of 5%.

Embodiment 2

[0020] Add 170 g of ethyl silicate, 111 g of hexamethyldisiloxane, 15 g of vinyl double caps, and 10 g of phenyl double caps in the three-necked flask, and mix well. At a reaction temperature of 8° C., 4 g of concentrated sulfuric acid and 30 g of water were slowly added dropwise, and after 1 h of reaction, the temperature was raised to reflux for 5 h, and 50 wt % KOH solution was added dropwise to adjust the system to be neutral. Then distilled with toluene and filtered to obtain a clear and transparent silicone resin toluene solution. The toluene solvent was distilled off to obtain 280 g of a clear and transparent silicone resin with a phenyl vinyl network structure, with a yield of 91% and a vinyl content of 5.5%.

Embodiment 3

[0022] Add 170 g of ethyl silicate, 111 g of hexamethyldisiloxane, 10 g of vinyl double caps, and 10 g of phenyl double caps in the three-necked flask, and mix well. At a reaction temperature of 8°C, 4 g of concentrated sulfuric acid and 30 g of water were slowly added dropwise, and after 1 h of reaction, the temperature was raised to reflux for 6 h, and 60 wt % KOH solution was added dropwise to adjust the system to be neutral. Then distilled with toluene and filtered to obtain a clear and transparent silicone resin toluene solution. The toluene solvent was distilled off to obtain 265 g of a clear and transparent silicone resin with a phenyl vinyl network structure, with a yield of 88% and a vinyl content of 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com