Method for processing dogwood

A processing method, the technology of Cornus officinalis, which is applied in the field of processing of Chinese medicinal materials, can solve the problems of the loss of active ingredients in the pulp of Cornus officinalis, affect the medicinal value of Cornus officinalis, and take a long time, so as to ensure the medicinal value, scientifically controllable the processing process, and reduce the loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A processing method of Cornus officinalis, comprising the following steps:

[0018] Rinse the fresh fruit of Cornus officinalis in water first;

[0019] Then put the fresh fruit of dogwood after rinsing in the barn, and bake it with charcoal fire for 2 minutes to separate the fruit of dogwood from the core;

[0020] Then put it into the denucleating machine for mechanical denucleation;

[0021] Put the pitted dogwood pulp in a microwave dryer, adjust the speed of the conveyor belt of the transmission device to 100-150r / min, and the drying time is 2 hours, so that the water content is controlled at 7-13%, and the finished product is obtained.

[0022] According to the regulations of the 2005 edition of "Chinese Pharmacopoeia", the content of loganin was determined by high performance liquid chromatography (HPLC) as the quality control index of Cornus officinalis. The specific determination method is as follows:

[0023] (1) Stationary phase: YWG-C18 column; mobile phas...

Embodiment 2

[0028] A processing method of Cornus officinalis, the other steps are the same as in Example 1, only the dried dogwood pulp after pitting is dried by drying: the pitted cornel pulp is placed in a baking tray in a barn, and the barn is controlled. The temperature is 65-70 ℃, and the kang is turned every 60-100 minutes, and dried until the water content of the pulp is 7-13%; the stacking thickness of the cornus pulp is preferably 2 / 3 of the height of the baking tray.

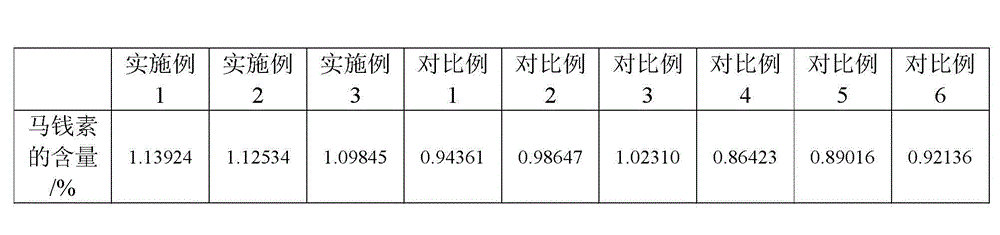

[0029] According to the HPLC determination method of loganin in Example 1, the content of loganin in the finished product prepared in this example was measured and calculated to be 1.12534% (see Table 1).

Embodiment 3

[0031] A processing method of cornus officinalis, other steps are the same as in embodiment 1, only the drying method of cornel officinalis pulp adopts natural drying.

[0032] According to the HPLC determination method of loganin in Example 1, the content of loganin in the finished product prepared in this example was measured and calculated to be 1.09845% (see Table 1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com