Flue gas dedusting and desulfurization and denitrification craft and special device thereof

A technology for desulfurization and denitrification, special equipment, applied in the direction of dispersed particle separation, chemical instruments and methods, combined devices, etc., can solve the problems of difficult waste liquid treatment, high investment cost, high energy consumption in operation, etc., achieve good denitrification and desulfurization efficiency, reduce Pollution, the effect of improving the removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

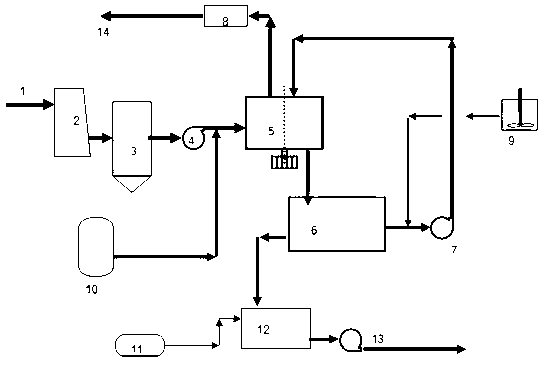

[0031] The present invention will be further clarified below in conjunction with the accompanying drawings. This specific embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these modes are only used to illustrate the present invention and not to limit the scope of the present invention.

[0032] A flue gas dedusting desulfurization and denitrification process, comprising:

[0033] (1) The flue gas first enters the waste heat utilization device for heat exchange and cooling, so that the temperature of the flue gas drops to about 150-180°C, and the cooled flue gas enters the bag filter to separate the dust in the flue gas and make the dust in the flue gas Concentration reduced to 30mg / m 3 ;

[0034](2) Blow a strong oxidant into the flue gas, and the oxidized flue gas enters the swirling double supergravity bed or static cyclone (or directly oxidizes in the swirling double supergravity bed or static reactor)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com