Catalytic cracking auxiliary agent and preparation method thereof

A catalytic cracking aid, sodium oxide technology, applied in the directions of catalytic cracking, chemical instruments and methods, cracking, etc., can solve the problems of metal pollution resistance and heavy oil conversion capacity need to be improved, increase the cost of auxiliary agents, and high prices, etc. The effect of reducing production cost, improving production efficiency, and high light oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] In the present invention, the non-ion-exchanged mesoporous silica-alumina material can be various mesoporous silica-alumina materials without any ion exchange commonly used in the art. The non-ion-exchanged mesoporous silica-alumina material can be prepared according to conventional methods, and the preparation method can include, for example, neutralizing the aluminum source and alkali solution at room temperature to 85°C to form a gel, and the final pH of the gel is 7 -11; then follow SiO 2 : Al 2 o 3 =1:0.6-9 weight ratio to add silicon source, aging at room temperature to 90°C for 1-10 hours, and then filter. In the present invention, the silica-alumina precipitate obtained after the filtration can be directly used as the non-ion-exchanged mesoporous silica-alumina material, or it can be used as the ion-free mesoporous silica-alumina material after being dried and / or calcined. Exchanged mesoporous silica-alumina materials.

[0023] In the present invention, the ...

Embodiment approach

[0035] According to a preferred embodiment of the present invention, the present invention provides a kind of preparation method of catalytic cracking additive, and this method comprises the following steps:

[0036] (1) Mix and beat the non-ion-exchanged mesoporous silica-alumina material with water to obtain a slurry, and then contact the obtained slurry with an inorganic acid at room temperature to 100°C for at least 0.2 hours to obtain a sodium oxide content of not higher than 0.2% by weight The mesoporous silica-alumina material, wherein the weight ratio of the non-ion-exchanged mesoporous silica-alumina material, water and inorganic acid is 1:5-30:0.03-0.3;

[0037] (2) Mix and beat the mesoporous silica-alumina material obtained in step (1), metal trapping agent, clay and / or heat-resistant inorganic oxide and / or heat-resistant inorganic oxide precursor, and then spray in sequence Dry, wash, filter and dry.

[0038] In the method of the present invention, only the prepa...

preparation Embodiment 1

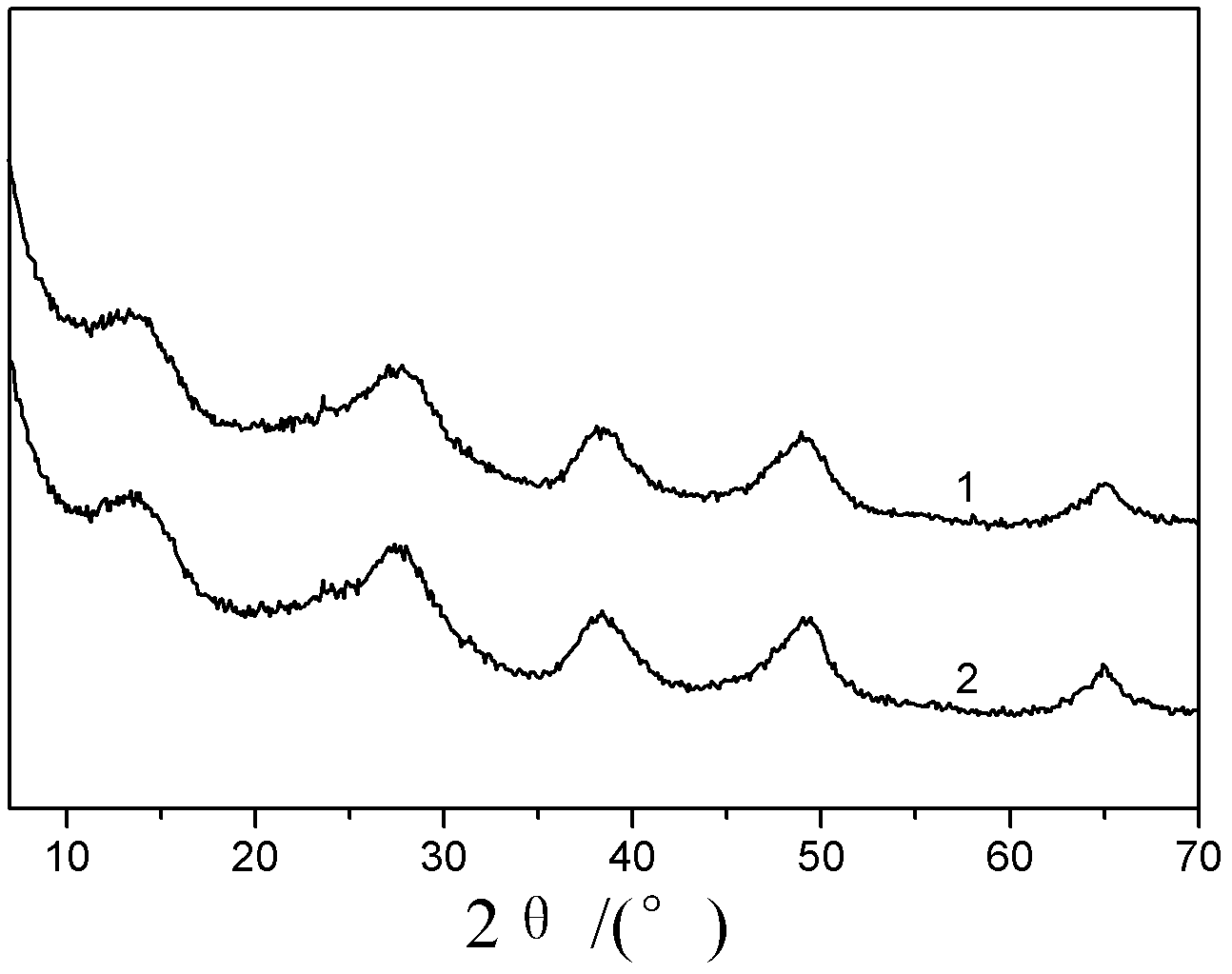

[0056] The preparation process of the mesoporous silicon-aluminum material SSA-1 is basically the same as that of the mesoporous silicon-aluminum material SA-1 in Example 1 of CN1565733A, except that the ammonium exchange process is replaced by an acid exchange process. The intermediate sediment of SA-1, i.e. the silicon-aluminum precipitate after aging and filtering, is mixed with water in a weight ratio of 1:10, and then the HCl solution (concentration is 10% by weight) is pressed into the sediment (dry basis): HCl=1:0.07 weight ratio was added to the above slurry, contacted at 55°C for 30 minutes, filtered, dried and calcined to obtain a mesoporous silica-alumina material, denoted as SSA-1. The X-ray diffraction spectrum of the sample is shown in figure 1 Curve 2 in . The elemental analysis gravimetric chemical composition of this sample is 0.14Na 2 O·73.6Al 2 o 3 26.1 SiO2 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com