hp series grinding roller open arc surfacing welding anti-shedding welding method

A welding method and anti-falling technology, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as large manpower and material resources, improper processing methods, and harsh environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

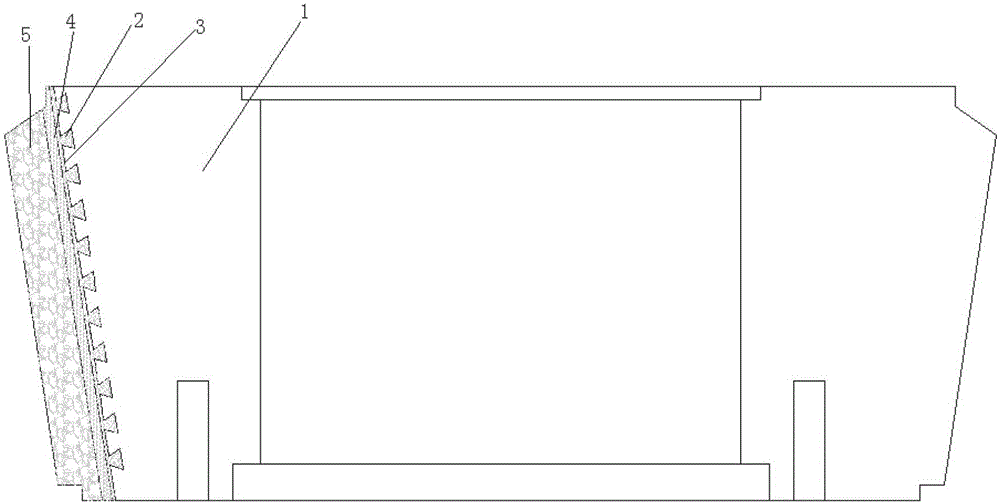

[0029] Referring to the attached figure, the anti-shedding welding method of HP series grinding roller open arc surfacing welding includes the following steps:

[0030] a. Pre-welding treatment:

[0031] 1. First, clean and polish the surface of the grinding roller 1, that is, use an angle grinder to install an iron brush to grind the grinding roller, remove the rust layer on the surface of the grinding roller 1, and wait until the surface of the grinding roller is completely exposed to the metal body to ensure that the grinding roller The surface is free of oil, rust and impurities, meeting the welding process requirements;

[0032] 2. Before the automatic surfacing welding of the grinding roller, use coloring and ultrasonic flaw detection to check whether there are any abnormal phenomena such as cracks, casting defects and local wear on the grinding roller, and check the chemical composition and mechanical properties of the grinding roller according to the regulations of DL / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com