Wastewater treatment device and method for in-situ electric generation of H2O2 cooperating with O3 oxidation

A technology of H2O2 and wastewater treatment, which is applied in the direction of oxidized water/sewage treatment, electrochemical water/sewage treatment, special compound water treatment, etc. It can solve the problems of limited oxidation capacity, great influence of pH, and unsuitable sewage, etc., to reduce The effect of treatment cost, wide pH range and good development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

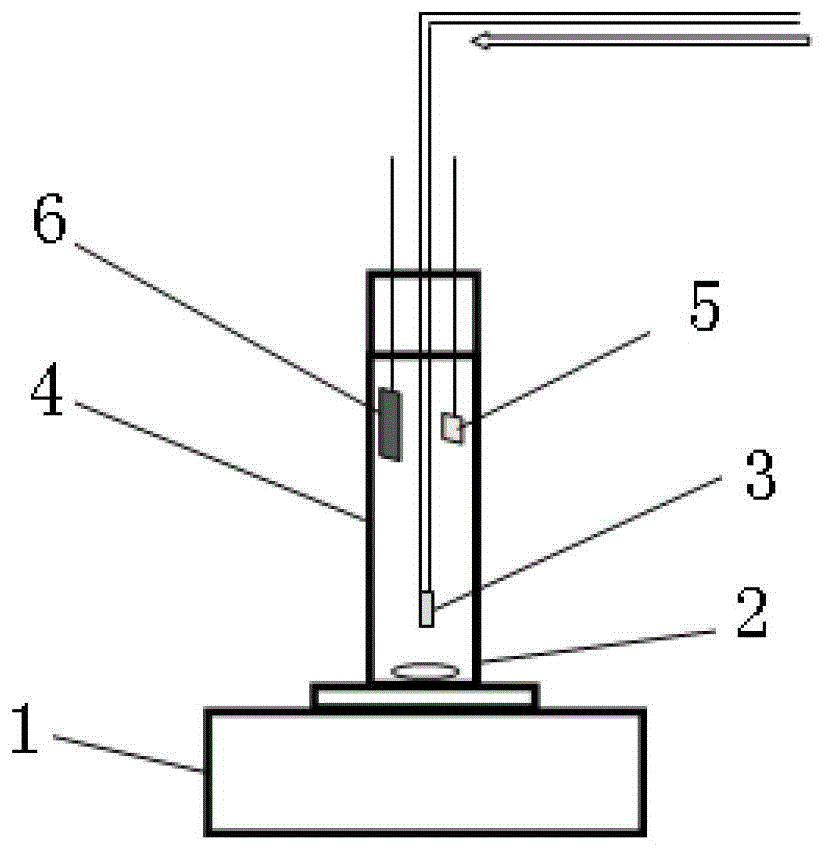

Image

Examples

Embodiment 1

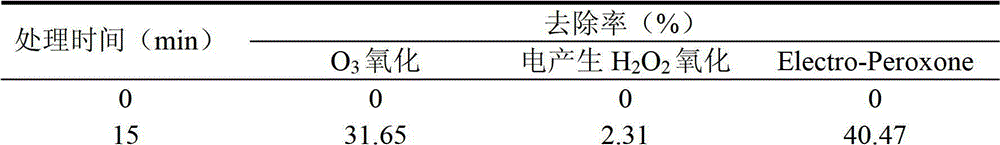

[0042] Example 1: with O 3 Oxidation, electricity to generate H 2 o 2 Comparison of Oxidation for Removal of Organic Matter

[0043] Experimental conditions: gas diffusion cathode 6 area: 10cm 2

[0044] Area of inert anode 5: 1cm 2

[0045] DC power supply: 100mA

[0046] Electrolyte: 0.05M Na 2 SO 4 the solution

[0047] o 3 Concentration: 60.82mg / L

[0048] Aeration flow rate: 0.4L / min

[0049] Initial TOC value of wastewater solution: 85ppm

[0050] Initial pH value of wastewater solution: 8.18

[0051] Note: The solution of waste water is Orange II aqueous solution, Orange II is a kind of dye, and its chemical formula is C 16 h 11 N 2 NaO 4 S; O 3 In the oxidation experiment, the mixed gas is directly exposed to the solution; the electricity generates H 2 o 2 The aeration gas in the oxidation experiment was pure oxygen.

[0052] Table 1 Comparison of removal effects of different treatment processes

[0053]

[0054]

[0055] Table 1 illustrat...

Embodiment 2

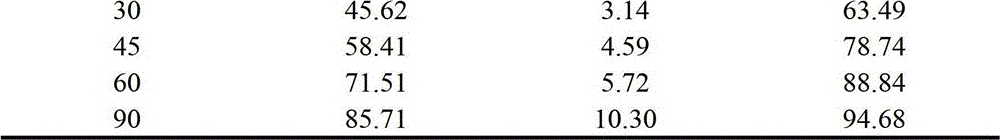

[0056] Embodiment 2.: Different electrolytic currents compare the removal of organic matter

[0057] Experimental conditions: gas diffusion cathode 6 area: 20cm 2

[0058] Area of inert anode 5: 1cm 2

[0059] DC power supply: 0mA, 200mA, 400mA,

[0060] o 3 Concentration: 60.82mg / L

[0061] Aeration flow rate: 0.3L / min

[0062] Initial TOC value of wastewater solution: 1550ppm

[0063] Initial pH value of wastewater solution: 7.91

[0064] Note: The treated solution is landfill leachate

[0065] Table 2 The influence of different electrolytic currents on the degradation results

[0066]

[0067] Table 2 shows that within the controlled current range, the greater the electrolysis current, the more electricity generated H 2 o 2 Collaborative O 3 The better the oxidation removal effect, this is due to the increase of current will generate more H 2 o 2 , improving the degradation efficiency.

Embodiment 3

[0068] Embodiment 3.: exposure to different concentrations of O 3 Comparison of removal of organic matter

[0069] Experimental conditions: gas diffusion cathode 6 area: 20cm 2

[0070] Area of inert anode 5: 1cm 2

[0071] DC power supply: 100mA

[0072] o 3 Concentration: 0mg / L, 30mg / L, 60.82mg / L

[0073] Aeration flow rate: 0.3L / min

[0074] Initial TOC value of wastewater solution: 1550ppm

[0075] Initial pH value of wastewater solution: 7.91

[0076] Note: The treated solution is landfill leachate

[0077] Table 3 Exposure to different concentrations of O 3 Influence on the degradation result

[0078]

[0079] Table 3 illustrates that as the exposed O 3 The higher the concentration, the higher the removal efficiency of landfill leachate, which is due to the production of more OH in the process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com