Method for processing and recycling strong brine by membrane desalination process

A technology of concentrated brine and process, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of low treatment utilization rate, waste of water resources, etc., and reduce treatment costs , the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

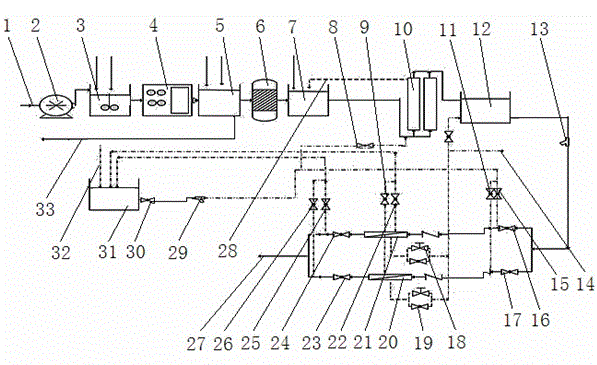

[0037] The main components of concentrated brine are: pH: 6.5~8.0, conductance ≤20000μs / cm, COD≤300mg / l, TDS≤15000mg / l, turbidity≤50 NTU, SS≤500 mg / l.

[0038] Go through the following steps:

[0039] A. Send the above-mentioned concentrated brine to be treated to the adjustment mixing tank 3 through the delivery pipe 1 and pump 2, adjust the pH value of the concentrated brine to 2.5, and then add H 2 o 2 with Fe 2+ Mix the reagents until the mass concentration of hydrogen peroxide in water is 0.05%, stir and mix, and use sulfuric acid to control the pH of the mixed solution to be 2.5, wherein: H 2 o 2 with Fe 2+ The molar ratio is: H 2 o 2 :Fe 2+ =1:2, Fe 2+ It is conventional ferrous sulfate;

[0040] B, the mixed solution of step A is sent in the microwave waste water treatment equipment 4, in the microwave field that frequency is 915MHz, and power is 5kW, process 5s;

[0041] C. Send the mixed solution processed by the microwave in step B to the sedimentation tan...

Embodiment 2

[0049] The main components of concentrated brine are: pH: 6.5-8.0, conductance ≤20000μs / cm, COD≤300mg / l, TDS≤15000mg / l, turbidity≤50 NTU, SS≤500 mg / l.

[0050] Go through the following steps:

[0051] A. Send the above-mentioned concentrated brine to be treated to the adjustment mixing tank 3 through the delivery pipe 1 and pump 2, adjust the pH value of the concentrated brine to 3.0, and then add H 2 o 2 with Fe 2+ Mix the reagents until the mass concentration of hydrogen peroxide in water is 0.1%, stir and mix, and use hydrochloric acid to control the pH of the mixed solution to be 3.0, wherein: H 2 o 2 with Fe 2+ The molar ratio is: H 2 o 2 :Fe 2+ =1:3, Fe 2+ It is conventional ferrous carbonate;

[0052] B, the mixed solution of step A is sent in the microwave waste water treatment equipment 4, in the microwave field that frequency is 2450MHz, and power is 40kW, process 10s;

[0053] C. Send the mixed solution processed by the microwave in step B to the sedimenta...

Embodiment 3

[0061] The main components of concentrated brine are: pH: 6.5-8.0, conductance ≤20000μs / cm, COD≤300mg / l, TDS≤15000mg / l, turbidity≤50 NTU, SS≤500 mg / l.

[0062] Go through the following steps:

[0063] A. Send the above-mentioned concentrated brine to be treated to the adjustment mixing tank 3 through the delivery pipe 1 and pump 2, adjust the pH value of the concentrated brine to 3.5, and then add H 2 o 2 with Fe 2+ Mix the reagents until the mass concentration of hydrogen peroxide in water is 0.6%, stir and mix, and use nitric acid to control the pH value of the mixed solution to be 3.5, wherein: H 2 o 2 with Fe 2+ The molar ratio is: H 2 o 2 :Fe 2+ =1:4.5, Fe 2+ It is conventional ferrous chloride;

[0064] B, the mixed solution of step A is sent in the microwave waste water treatment equipment 4, in the microwave field that the frequency is 915MHz and 2450MHz, and the power is 150kW, process successively for a total of 20s;

[0065] C. Send the mixed solution proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com