Toughened glass cooling method and toughening furnace cooling system

A technology of tempered glass and cooling method, applied in the direction of tempering glass, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of increasing fan capacity, increasing cost, increasing power consumption, etc., reducing installed capacity, reducing Operating cost, effect of reducing air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

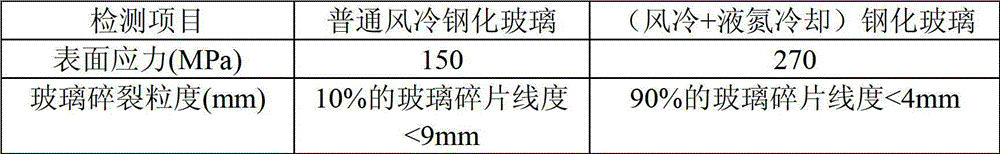

[0025] Embodiment 1: Production of ordinary tempered glass

[0026] This embodiment compares the effects of ordinary tempering and tempering with the cooling system of the present invention.

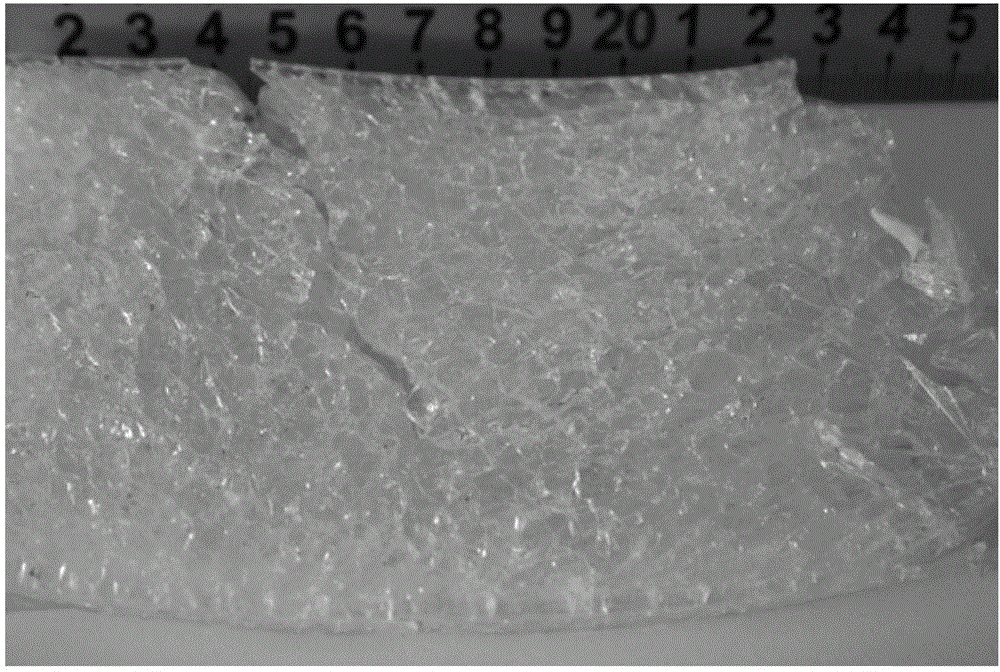

[0027] Sample: 6mm glass, the corresponding labels of the same glass are divided into 2 groups, a total of 12 pieces of glass are divided into 2 groups for testing, and the strength of ordinary air-cooled tempered glass and the strength of liquid nitrogen cooled tempered glass of the present invention are tested, and the results are compared;

[0028] Tempering conditions and operation:

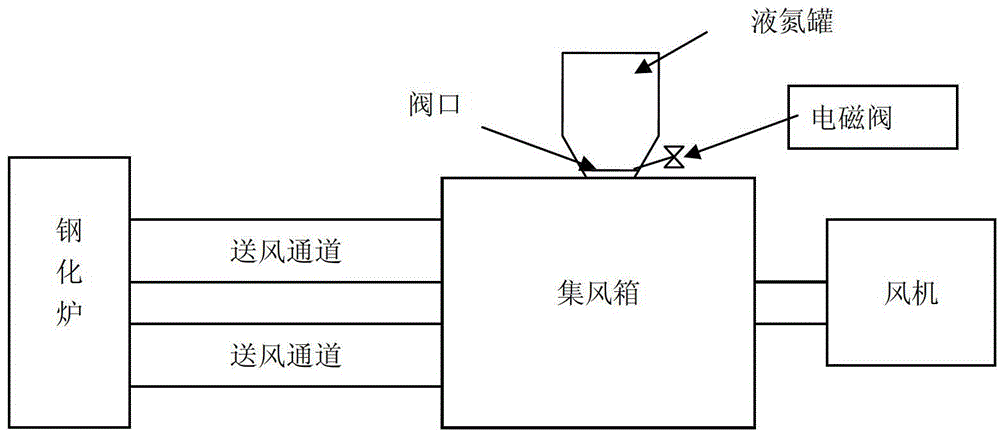

[0029] In a small tempering furnace, the installed capacity of the fan is 30KW, and the temperature at the air inlet of the tempering furnace is 35°C in summer. A liquid nitrogen tank with a volume of 20 liters is installed at the upper part of the air collecting box at the back of the tempering furnace fan, and it is filled with liquid nitrogen before the air cooling is started and sealed. 5 seconds ...

Embodiment 2

[0034] Embodiment 2: Production of thin tempered glass

[0035] For thinner glass, such as 3mm glass, it is difficult to form an effective stress layer inside the glass due to the thinner glass. Therefore, the effect of ordinary wind tempering methods on 3mm glass is not obvious, and wind tempering is generally not used.

[0036] In this embodiment, the corresponding 3mm glass sample is tempered by using the method of the present invention and the common tempering method.

[0037] Tempering conditions and operations are the same as those in Example 1, wherein the blower blowing speed is 10m 3 / S, the injection volume of liquid nitrogen is 20 liters, and the injection is completed in 10 seconds; the temperature of the mixed cooling medium at the air inlet of the tempering furnace is minus 20°C, and the mixed cooling wind speed is 12m 3 / second.

[0038] Detection: Same as in Example 1, the data obtained by the polarizer strain gauge are shown in Table 2.

[0039] Table 2: St...

Embodiment 3

[0043] Embodiment 3: Production of tempered glass

[0044] In this application, over-tempered glass refers to tempered glass with an additional strength exceeding 105MPa obtained through physical tempering on the basis of the strength of the original glass sheet for 12mm glass. The common air tempering method cannot produce tempered glass due to insufficient cooling capacity of the equipment.

[0045] In this embodiment, a group of 12mm glass samples are tempered by the method of the present invention to produce tempered glass.

[0046] Tempering conditions and operations are the same as those in Example 1, wherein the blower blowing speed is 100m 3 / S, the injection volume of liquid nitrogen is 20 liters, and the injection is completed in 10 seconds; the temperature of the mixed cooling medium at the air inlet of the tempering furnace is minus -20°C, and the mixed cooling wind speed is 12m 3 / second.

[0047] Detection: Use a polarizer stress meter to detect the surface st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com