Preparation method of up-conversion fluorescent material

A technology of fluorescent materials and raw materials, applied in the field of preparation of rare earth up-conversion luminescent nanomaterials, which can solve problems such as experimental operation hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

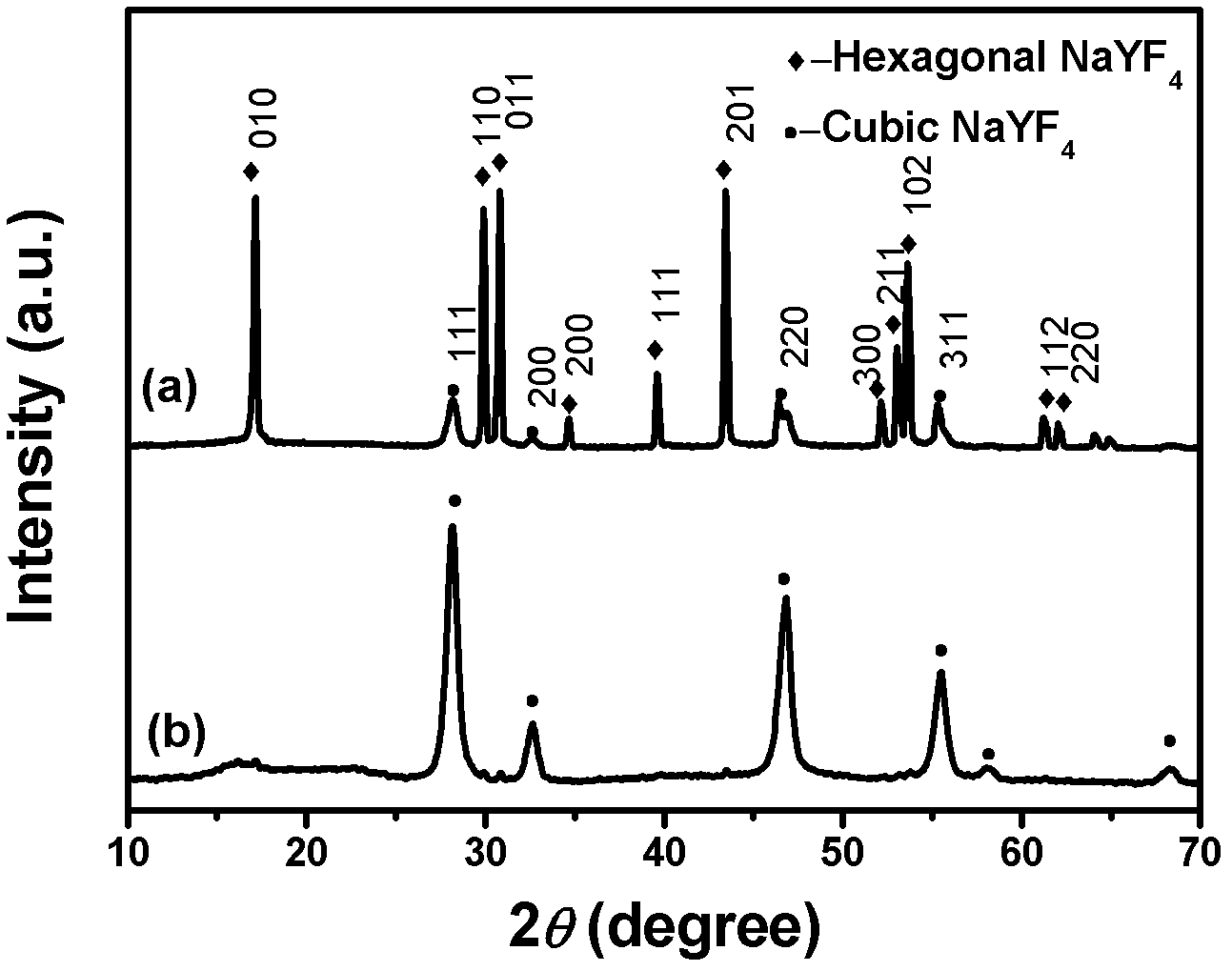

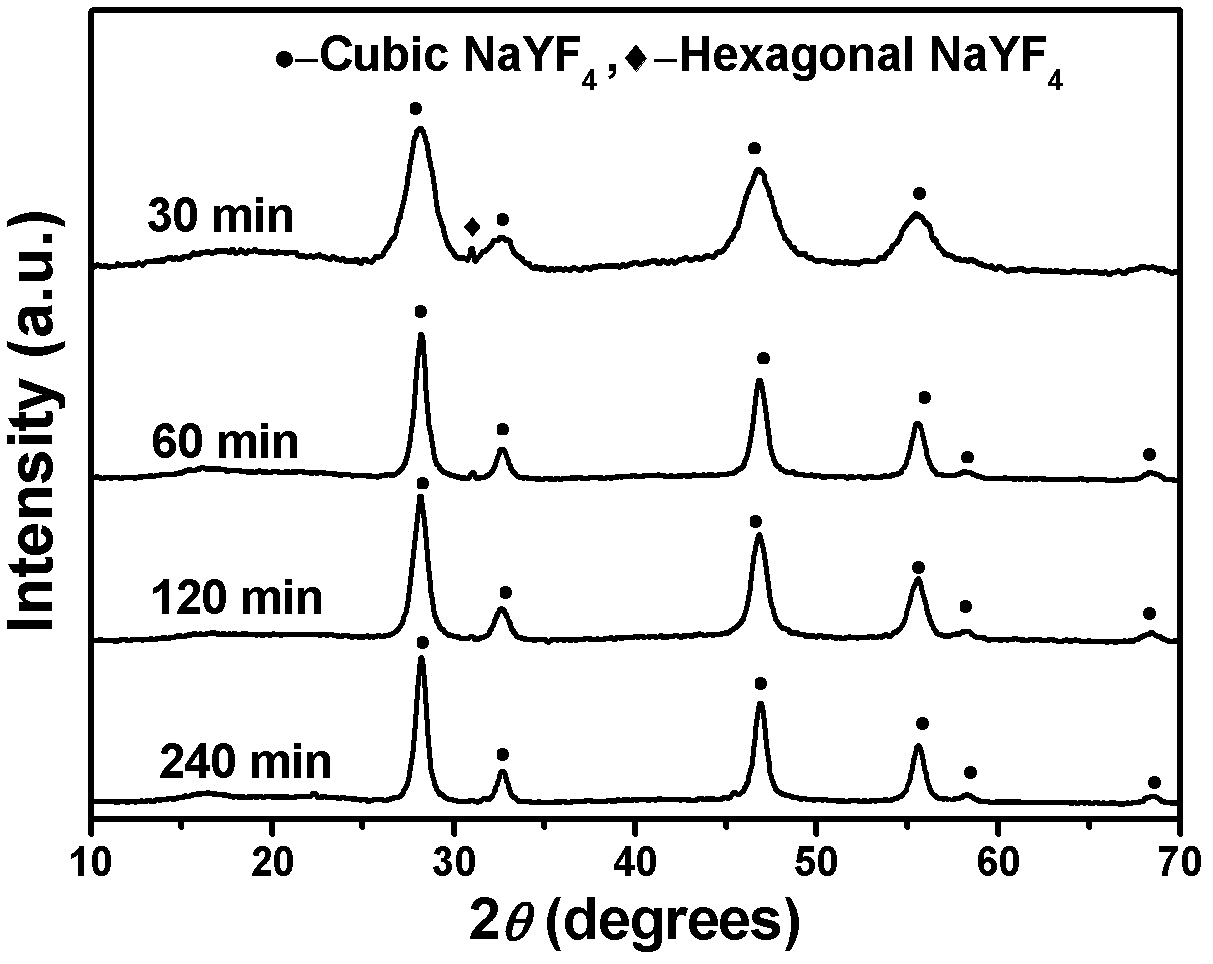

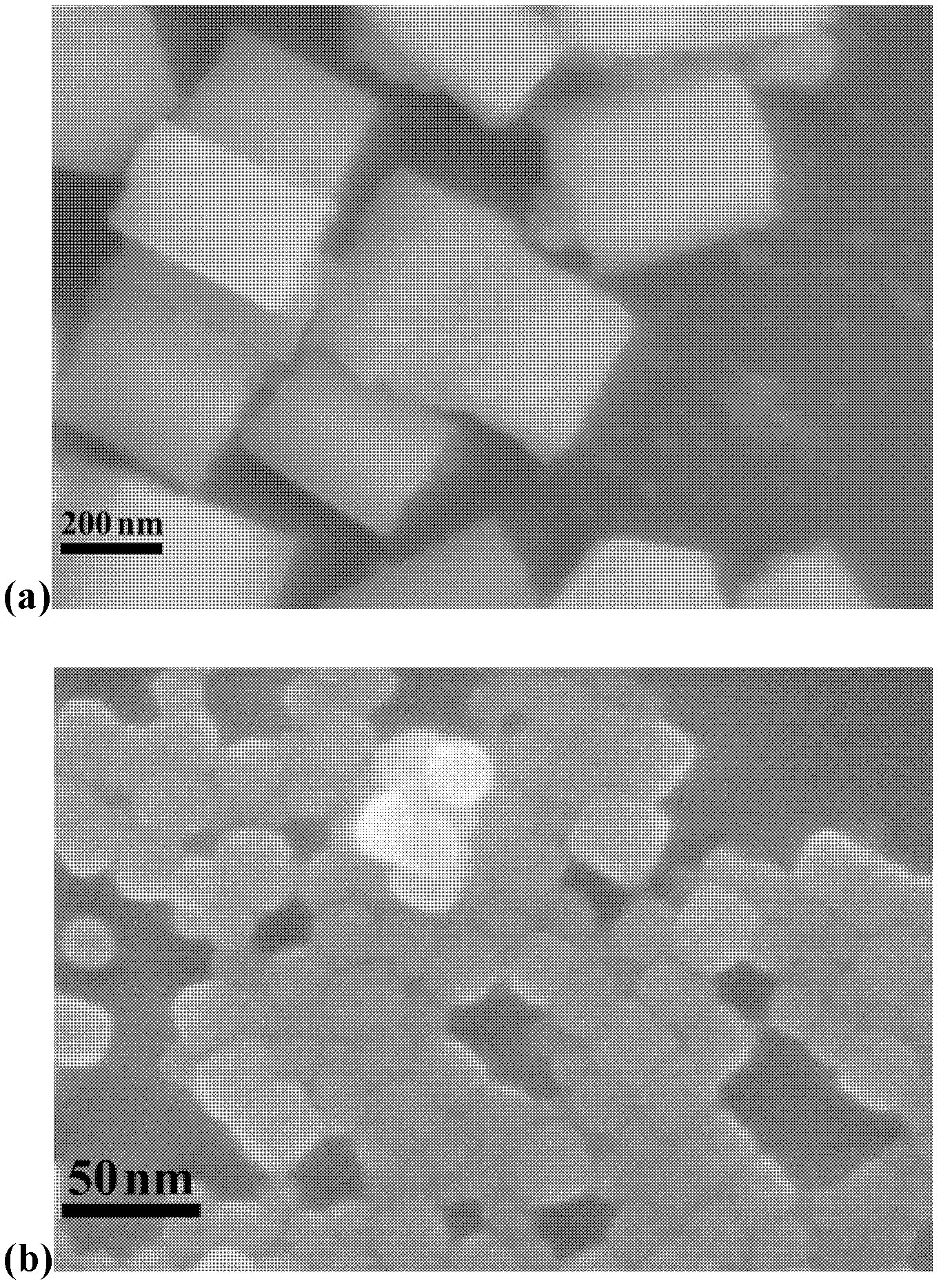

Method used

Image

Examples

Embodiment 1

[0072] (i) prepare an aqueous solution comprising Y, Yb, Er, Mn, including 1.0 mmol of Ln (NO 3 ) 3 (Ln=0.8mmol Y+0.18mmol Yb+0.02mmol Er), Mn: Y=30% (mol percentage);

[0073] (ii) Take sodium hydroxide (0.3g), double-distilled water (2mL), ethanol (10mL) and oleic acid (5mL), and mix them uniformly to obtain a mixed solution;

[0074] (iii) adding the solution of step (i) to the mixed solution of step (ii), stirring for 45min;

[0075] (iv) Add 4 mmol of NaF to the mixed solution obtained in step (iii), stir evenly, seal, hydrothermally treat at 180° C. for 12 hours, and then cool;

[0076] (v) centrifuged, washed twice with ethanol, water and ethanol in sequence, and dried to obtain the obtained product.

Embodiment 2

[0078] (i) prepare an aqueous solution comprising Y, Yb, Er, Mn, including 1.0 mmol of Ln (NO 3 ) 3 (Ln=0.8mmol Y+0.15mmol Yb+0.05mmol Er), Mn: Y=5% (mol percentage);

[0079] (ii) Take sodium hydroxide (0.6g), twice-distilled water (4mL), ethanol (10mL) and oleic acid (10mL), and mix them uniformly to obtain a mixed solution;

[0080] (iii) adding the solution of step (i) to the mixed solution of step (ii), stirring for 30min;

[0081] (iv) Add 6 mmol of NaF to the mixed solution obtained in step (iii), stir evenly, seal, hydrothermally treat at 180° C. for 8 hours, and then cool;

[0082] (v) centrifuged, washed twice with ethanol, water and ethanol in sequence, and dried to obtain the obtained product.

Embodiment 3

[0084] (i) prepare an aqueous solution comprising Y, Yb, Er, Mn, including 1.0 mmol of Ln (NO 3 ) 3 (Ln=0.65mmol Y+0.3mmol Yb+0.05mmol Er), Mn: Y=10% (mol percentage);

[0085] (ii) Take sodium hydroxide (0.3g), twice-distilled water (4mL), ethanol (10mL) and oleic acid (5mL), and mix them uniformly to obtain a mixed solution;

[0086] (iii) adding the solution of step (i) to the mixed solution of step (ii), stirring for 45min;

[0087] (iv) Add 10 mmol of NaF to the mixed solution obtained in step (iii), stir evenly, seal, hydrothermally treat at 200° C. for 12 hours, and then cool;

[0088] (v) centrifuged, washed twice with ethanol, water and ethanol in sequence, and dried to obtain the obtained product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com