A kind of er3+/pr3+ co-doped yttrium lithium fluoride single crystal and its preparation method

A technology of yttrium lithium fluoride and single crystal, which is applied in the field of Er3+/Pr3+ co-doped yttrium lithium fluoride single crystal and its preparation, can solve the problems of rare rare earth active ion sensitization and other problems, and achieves low phonon energy and enhanced fluorescence Low emission efficiency, thermal lensing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

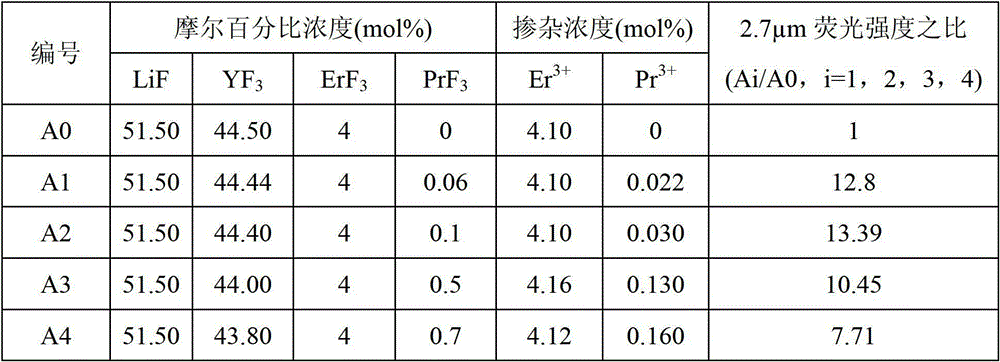

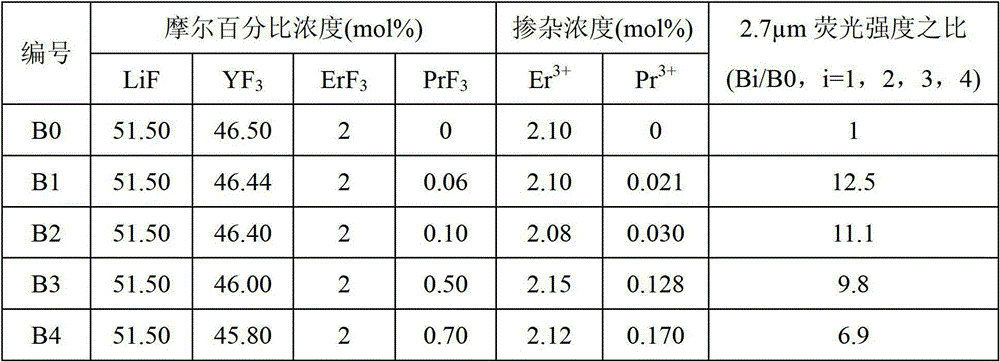

[0022]The single crystal materials of Examples A1~A4 and Comparative Example A0 were respectively prepared by the same preparation method, that is, the proportioning and weighing were carried out according to the molar percentage concentration of the components in Table 1, and the purity of the raw materials used were all greater than 99.99%. After mixing, put it in a mill, grind and mix for 5 hours to obtain a uniform powder; put the above powder loosely in a boat-shaped platinum crucible, and then install the boat-shaped platinum crucible in the platinum pipeline of the tubular resistance furnace; Then use high-purity N 2 Gas removes the air in the platinum pipeline, and conducts leak detection on the platinum pipeline; then gradually raises the temperature of the furnace body of the tubular resistance furnace to 800°C, passes HF gas, and reacts for 2 hours to remove possible H 2 O and oxyfluoride, absorb the HF gas in the tail gas with NaOH solution during the reaction proc...

Embodiment C1

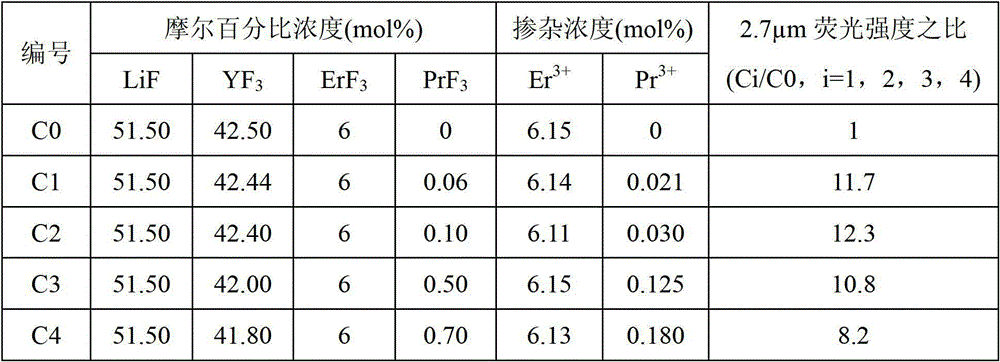

[0033] Embodiment C1, C2, C3, C4 and comparative example C0:

[0034] The single crystal materials of Examples C1~C4 and Comparative Example C0 were respectively prepared by the same preparation method, that is, the proportioning and weighing were carried out according to the composition of the molar percentage concentration in Table 3, and the purity of the raw materials used were all greater than 99.99%. After mixing, put it in a mill, grind and mix for 5 hours to obtain a uniform powder; put the above powder loosely in a boat-shaped platinum crucible, and then install the boat-shaped platinum crucible in the platinum pipeline of the tubular resistance furnace; Then use high-purity N 2 Gas removes the air in the platinum pipe, and conducts leak detection on the platinum pipe; then gradually raises the temperature of the furnace body of the tube resistance furnace to 800°C, passes HF gas, and reacts for 4 hours to remove possible H 2 O and oxyfluoride, during the reaction pr...

Embodiment D1、D2、D3、D4 and comparative example D0

[0040] The single crystal materials of Examples D1-D4 and Comparative Example D0 were respectively prepared by the same preparation method, that is, the proportioning and weighing were carried out according to the molar percentage concentration of the components in Table 3, and the purity of the raw materials used were all greater than 99.99%. After mixing, put it in a mill, grind and mix for 5 hours to obtain a uniform powder; put the above powder loosely in a boat-shaped platinum crucible, and then install the boat-shaped platinum crucible in the platinum pipeline of the tubular resistance furnace; Then use high-purity N 2 Gas removes the air in the platinum pipeline, and conducts leak detection on the platinum pipeline; then gradually raises the furnace body temperature of the tubular resistance furnace to 800°C, passes HF gas, and reacts for 2.5 hours to remove possible H 2 O and oxyfluoride, during the reaction process, use NaOH solution to absorb HF gas in the tail gas. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com