Fluorescent powder for white light luminescent diode and preparing method thereof

A technology of light-emitting diodes and phosphors, applied in the direction of luminescent materials, chemical instruments and methods, and the use of gas discharge lamps, etc., can solve the problems of not being able to meet the needs of semiconductor lighting applications, low luminous brightness and efficacy, and achieve improved luminescence Brightness, reduction of raw material cost, high luminance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

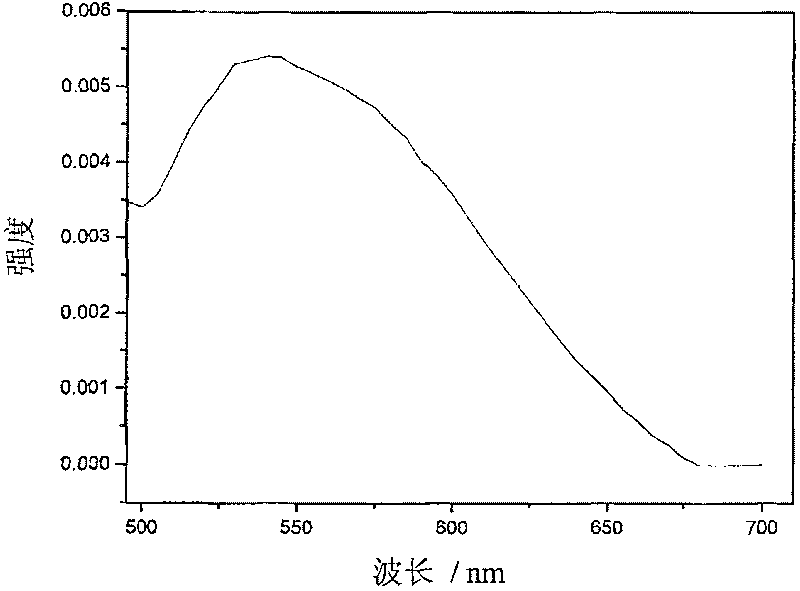

Embodiment 1

[0042] The purity of the raw material is 99.99-99.999%, and the d of the powder is 50 = 2 ~ 4μm, d 90 10 >0.5μm Y 2 o 3 10.17g, Lu 2 o 3 1.0g, Gd 2 o 3 0.14g, Al 2 o 3 8.43g, SiO 2 0.07g, CeO 2 0.41g, Dy 2 o 3 0.01g, BaF 2 0.45g, H 3 BO 3 0.15g, after mixing evenly, put it into a corundum crucible, 2 -H 2 Under the protection of mixed gas, keep warm at 1450°C for 3 hours, cool to room temperature with the furnace, pulverize the primary synthetic powder, pass through a 300-mesh sieve, and place it in HNO with a concentration of 0.1M and a temperature of 70°C 3 solution, after stirring for 30min, wash with deionized water until neutral, wash twice with absolute alcohol, and dry; dry the dried powder again in N 2 -H 2 In a mixed atmosphere at 1520°C, hold for 6 hours, cool down to room temperature with the furnace, pulverize through a 350-mesh sieve, and obtain the chemical structure formula (Y 2.70 Lu 0.15 Gd 0.025 )(Al 4.965 Si 0.035 )O 12 : Ce 0.07 , ...

Embodiment 2

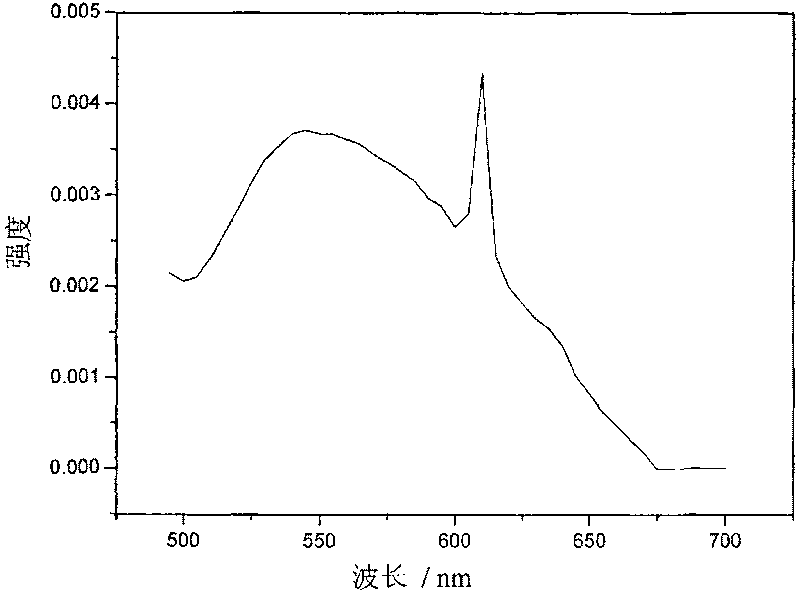

[0044] The purity of the raw material is 99.99-99.999%, and the d of the powder is 50 = 2 ~ 4μm, d 90 10 >0.5μm Y 2 o 3 9.97g, Lu 2 o 3 1.33g, Gd 2 o 3 0.011g, Al 2 o 3 8.46g, SiO 2 0.03g, CeO 2 0.29g, Pr 6 o 11 0.011g, AlF 3 0.3g, H 3 BO 3 0.2g, after mixing evenly, put it into a corundum crucible, 2 -H 2 Under the protection of mixed gas, keep warm at 1350°C for 2 hours, cool to room temperature with the furnace, pulverize the primary synthetic powder, pass through a 350-mesh sieve, put it in a HNO3 solution with a concentration of 0.8M and a temperature of 80°C, stir for 30 minutes, and use a deionized Wash with water until neutral, wash twice with absolute alcohol, and dry; dry the dried powder again in N 2 -H 2 In a mixed atmosphere at 1520°C, hold for 6 hours, cool down to room temperature with the furnace, pulverize through a 350-mesh sieve, and obtain the chemical structure formula (Y 2.65 Lu 0.2 Gd 0.0018 )(Al 4.98 Si 0.015 )O 12 : Ce 0.05 , ...

Embodiment 3

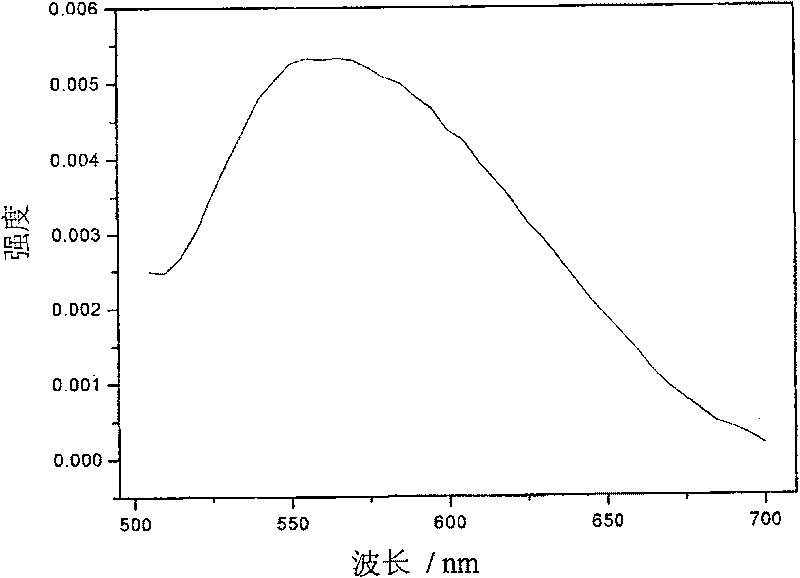

[0046] The purity of the raw material is 99.99-99.999%, and the d of the powder is 50 = 2 ~ 4μm, d 90 10 >0.5μm Y 2 o 3 8.99g, Lu 2 o 3 0.026g, Gd 2 o 3 3.63g, Al 2 o 3 8.47g, SiO 2 0.028g, CeO 2 0.69g, Dy 2 o 3 0.062g, AlF 3 0.2g, H 3 BO 3 0.45g, NH 4 After F0.2g is mixed evenly, put it into a corundum crucible, 2 -H 2 Under the protection of mixed gas, keep warm at 1350°C for 2 hours, cool down to room temperature with the furnace, pulverize the primary synthetic powder, pass through a 350 mesh sieve, and place it in HNO with a concentration of 0.8M and a temperature of 80°C 3 solution, after stirring for 30min, wash with deionized water until neutral, wash twice with absolute alcohol, and dry; dry the dried powder again in N 2 -H 2 In a mixed atmosphere at 1520°C, hold for 6 hours, cool down to room temperature with the furnace, pulverize through a 350-mesh sieve, and obtain the chemical structure formula (Y 2.39 Lu 0.004 Gd 0.6 )(Al 4.986 Si 0.014 )...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com