Energy collection unit and ratchet wheel and a wave force engine

A technology of energy harvesting and ratcheting, which is applied to engine components, machines/engines, and ocean energy power generation. It can solve problems such as poor adaptability to the operating environment, long construction period, and many energy conversion links, and achieve low production and operating costs. The effect of simple and fast maintenance and less conversion links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

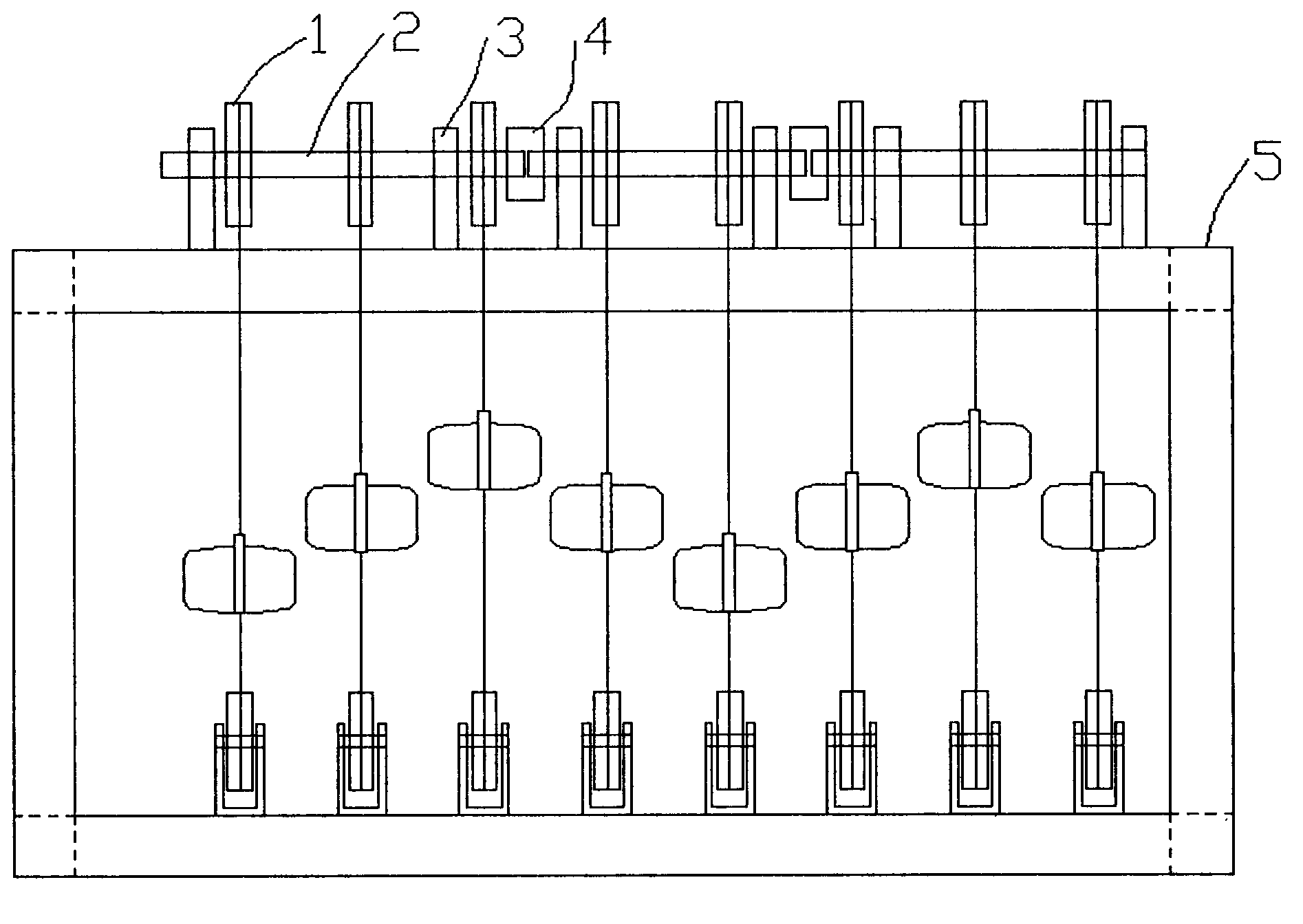

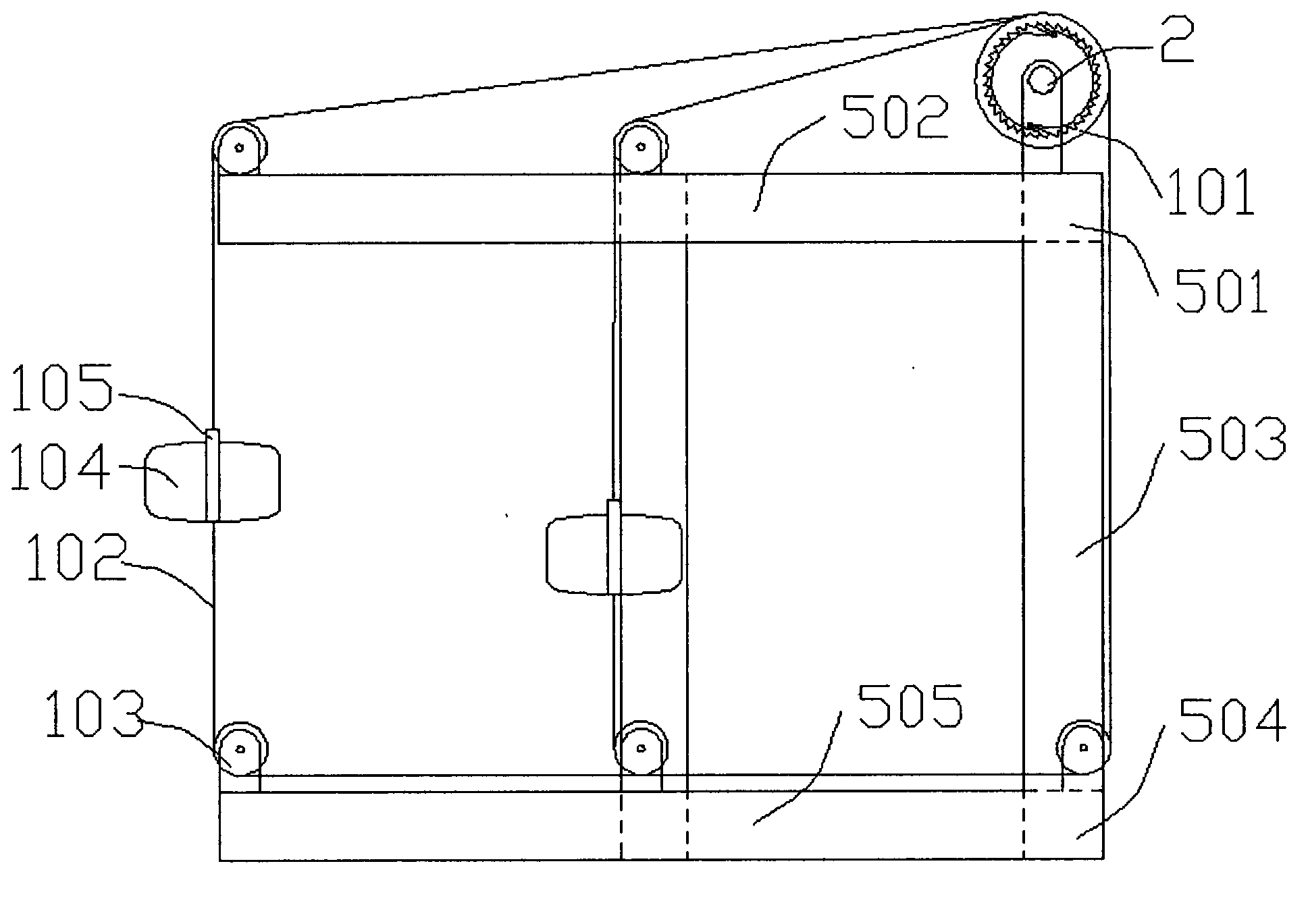

[0044] Example 1: see figure 1 A wave power engine of the present invention is composed of a frame 5, a synchronizing shaft 2, a bearing seat 3, and an energy harvesting unit 1, and the synchronizing shaft 2 is also a power output shaft; figure 2 It is shown that the frame 5 includes an upper platform composed of an upper longitudinal beam 501 and an upper transverse beam 502, a lower platform composed of a column 503, a lower longitudinal beam 504 and a lower transverse beam 505. The frame 5 is prefabricated with reinforced concrete, or can be Manufactured from metal materials (such as steel) or plastic-steel composite materials or other materials, prefabricated or integrated in the workshop, and fixedly installed in rivers, lakes or oceans rich in wave energy through pile platforms (pile foundation platforms), the frame height is 5 and the piles The height of the platform is determined according to the maximum wave height and maximum tidal range of the location. It should b...

Embodiment 2

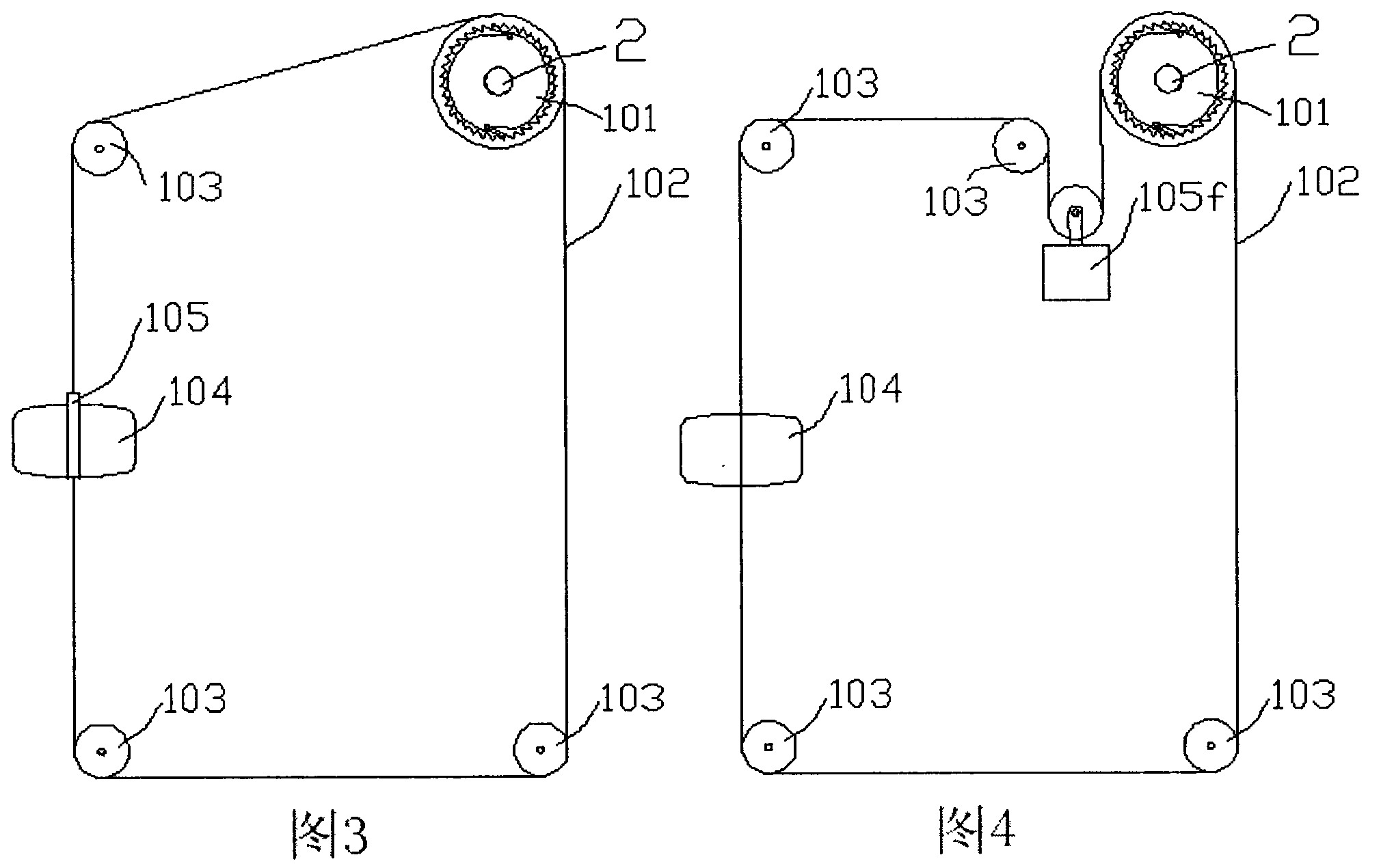

[0045] Embodiment 2: This example has the same frame 5, synchronizing shaft 2, bearing seat 3 as in Embodiment 1, and the synchronizing shaft 2 is also the structure and arrangement of the power take-off shaft, as well as descriptions. In order to save space, the description will not be repeated here. The difference lies in the energy harvesting unit 1, strictly speaking, only in the ratchet device 101; see Figure 7 , Figure 8 , Figure 9 , Figure 10 , it is more preferable to use an energy storage ratchet, the energy storage ratchet includes ratchet wheels 101a, 101f, a ratchet wheel seat 101b, a pawl 101c, springs 101d, 101e, bearings 101h, 101g, the ratchet wheel seat 101b is installed with two identical The ratchet wheels 101a and 101f are oriented in the opposite direction, and one or more pawls 101c are used to limit the rotation of the ratchet wheel seat 101b in only one direction. The mainspring) transmits power to the synchronizing shaft 2, and is installed on t...

Embodiment 3

[0046] Embodiment 3: This embodiment has the same frame 5, synchronizing shaft 2, bearing seat 3 as Embodiment 1 or Embodiment 2, and the synchronizing shaft 2 is also a power output shaft and other structures, layouts and descriptions. To save space, they are omitted here. To repeat the description again, the difference lies in the energy harvesting unit 1, and the emphasis lies in the difference in the preloading device 105; see Figure 4 , in this example, the energy harvesting unit 1 is composed of a ratchet device 101, a pulley 103, a float 104, a transmission chain, and a heavy hammer device 105f. Suspending a group of heavy weight blocks on the transmission chain between them through the pulley 103 can also play the same effect as the preload spring, and can have a larger working distance; one end of the transmission chain is fixed at the lower part of the float 104, and the other end is wound around. Over the pulley 103, the weight between the pulley 103 and the ratche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com