Hydrogen peroxide propellant filling and supercharging operating platform

A hydrogen peroxide and propellant technology, which is used in the testing of measuring devices, instruments, machinery/structural components, etc., can solve the problems of unsuitable filling and pressurization, large and complex problems, and achieves a small footprint and simplifies the pressurization operation. Process, easy to adjust the effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the drawings.

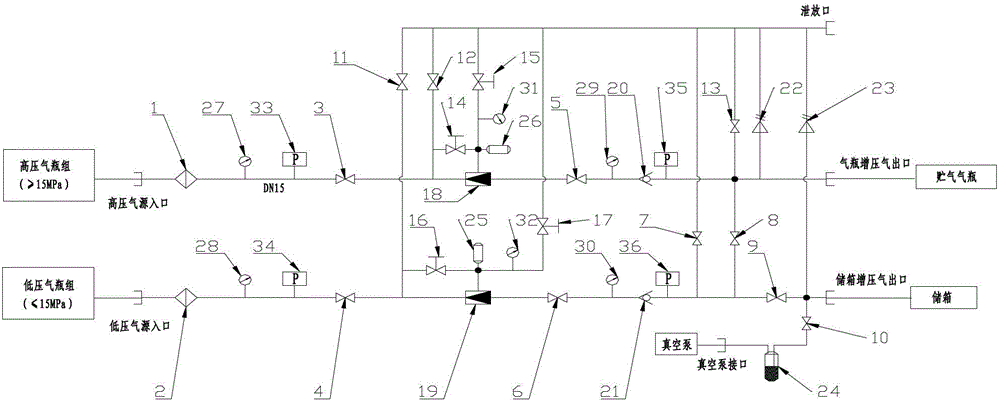

[0035] The present invention is a hydrogen peroxide propellant filling and pressurizing operation table, comprising a high-pressure pressurizing gas circuit, a low-pressure pressurizing gas circuit and a hydrogen peroxide filling gas circuit; wherein, the high-pressure pressurizing gas circuit includes a first filter 1. The first manual stop valve 3, the third manual stop valve 5, the tenth manual stop valve 12, the eleventh manual stop valve 13, the first pressure reducer 18, the first check valve 20, and the first safety valve 22 The high-pressure booster main circuit is composed of the first throttle valve 14, the second buffer tank 26, and the second throttle valve 15, and the high-pressure pressure reducer control circuit is composed of the first pressure gauge 27 and the third pressure gauge. 29. The high-pressure pressure monitoring system composed of the fifth pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com