Fabrication method of rectifier diode

A technology of a rectifier diode and a manufacturing method, which is applied in the manufacturing of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of not being able to achieve optimal distribution of minority carrier lifetime, reducing minority carrier lifetime, large on-state voltage drop, etc., and improving blocking Volt-ampere characteristics and current density, improved reliability, small effect of on-state voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific embodiment:

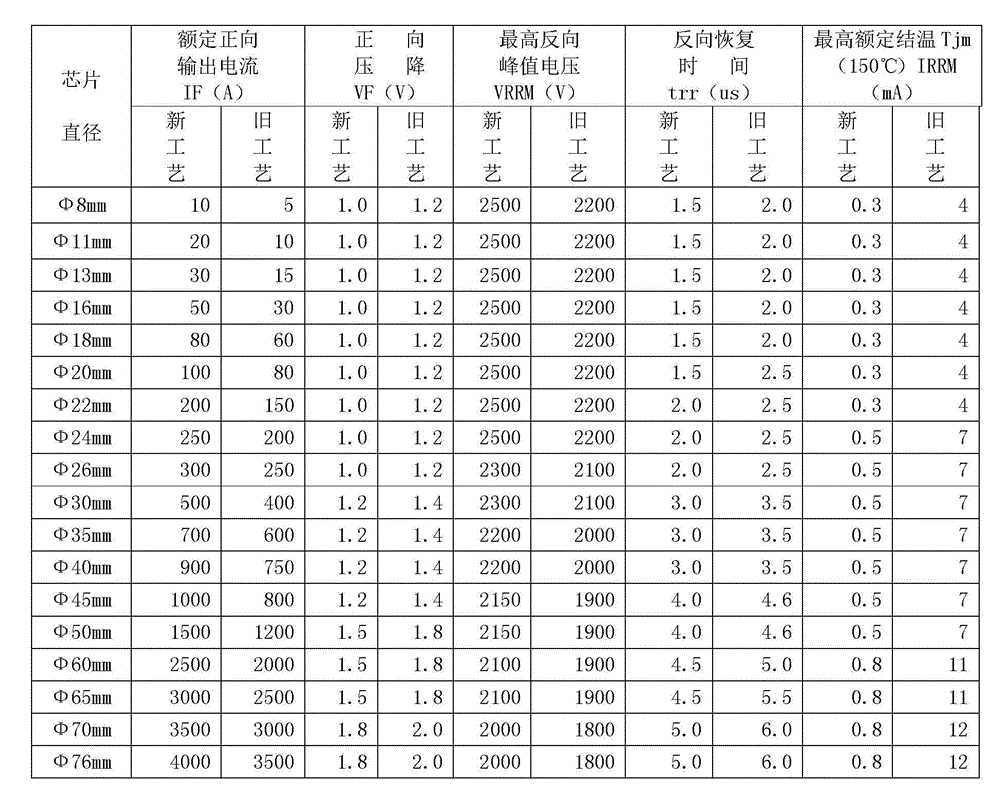

[0028] The invention discloses a manufacturing method of sub-dense sub-dense rectifier diodes, which comprises supersanding of silicon wafers, cleaning of silicon wafers, cleaning of quartz frames and quartz ingots, diffusion, detection, and manufacturing steps of diffusion sources. Phosphorus, boron, and platinum liquid sources are used once. The full diffusion process makes the surface concentration distribution uniform, and realizes the optimal distribution of minority carrier lifetime through the absorption of phosphosilicate glass. The specific operation steps are as follows:

[0029] 1) Silicon wafer super sand

[0030] Place the silicon wafer on a high-temperature PTFE rack, put it into the cleaning solution, the ratio of the cleaning solution is, electronic cleaning solution: deionized water = 2.7ml: 1000ml, ultrasonic cleaning for 30 to 40 minutes, and then use 60 °...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com