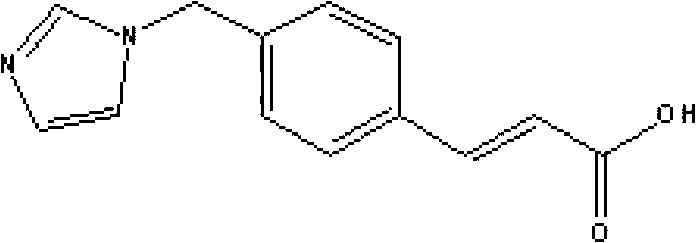

Medicinal composition containing sodium ozagrel compound

A technology of sodium ozagrel and its composition, which is applied in the field of freeze-dried powder injection of sodium ozagrel and its preparation, can solve the problems of inconvenient use and unsatisfactory dissolution speed, and achieve convenient use, rapid dissolution and stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

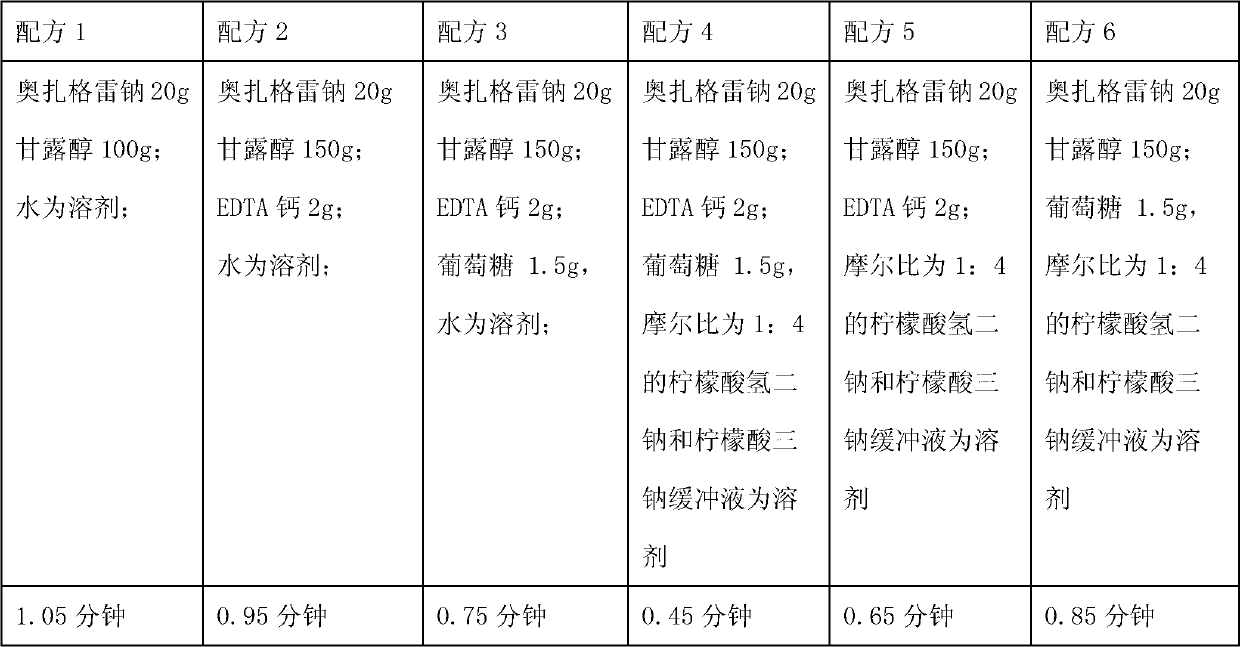

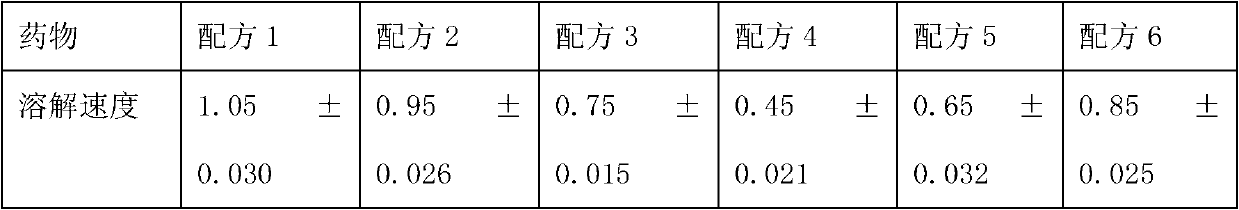

Examples

Embodiment 1

[0061] Ozagrel sodium 20g;

[0062] Mannitol 150g;

[0063] Calcium EDTA 2g;

[0064] Glucose 1.5g,

[0065] 2000ml of disodium hydrogen citrate and trisodium citrate buffer solution with a molar ratio of 1:4;

[0066] Preparation

[0067] (1) Weigh the raw and auxiliary materials according to the prescription quantity

[0068] (2) Add mannitol, EDTA calcium, and glucose to 1000ml of disodium hydrogen citrate and trisodium citrate buffer solution with a molar ratio of 1:4, and stir to dissolve.

[0069] (3) Add the prescribed amount of sodium ozagrel into the solution and stir to dissolve completely. Add disodium hydrogen citrate and trisodium citrate buffer with a molar ratio of 1:4 to the full amount, and stir to mix evenly.

[0070] (4) Measure the pH of the solution to be 7.0.

[0071] (5) Fine filter with a 0.2 μm microporous membrane to check the clarity of the solution.

[0072] (6) According to the measurement results, fill the liquid medicine into a vial with ...

Embodiment 2

[0076] Ozagrel sodium 20g;

[0077] Mannitol 100g;

[0078] Calcium EDTA 1g;

[0079] Glucose 1g,

[0080] 2000ml of disodium hydrogen citrate and trisodium citrate buffer solution with a molar ratio of 1:4;

[0081] Preparation

[0082] (1) Weigh the raw and auxiliary materials according to the prescription quantity

[0083] (2) Add mannitol, EDTA calcium, and glucose to 1000ml of disodium hydrogen citrate and trisodium citrate buffer solution with a molar ratio of 1:4, and stir to dissolve.

[0084] (3) Add the prescribed amount of sodium ozagrel into the solution and stir to dissolve completely. Add disodium hydrogen citrate and trisodium citrate buffer with a molar ratio of 1:4 to the full amount, and stir to mix evenly.

[0085] (4) Measure the pH value of the solution, which is 7.0.

[0086] (5) Fine filter with a 0.2 μm microporous membrane to check the clarity of the solution.

[0087] (6) According to the measurement results, fill the liquid medicine into a vial...

Embodiment 3

[0091] Ozagrel sodium 20g;

[0092] Mannitol 200g;

[0093] Calcium EDTA 3g;

[0094] Glucose 2g,

[0095] 2000ml of disodium hydrogen citrate and trisodium citrate buffer solution with a molar ratio of 1:4;

[0096] Preparation

[0097] (1) Weigh the raw and auxiliary materials according to the prescription quantity

[0098] (2) Add mannitol, EDTA calcium, and glucose to 1000ml of disodium hydrogen citrate and trisodium citrate buffer solution with a molar ratio of 1:4, and stir to dissolve.

[0099] (3) Add the prescribed amount of sodium ozagrel into the solution and stir to dissolve completely. Add disodium hydrogen citrate and trisodium citrate buffer with a molar ratio of 1:4 to the full amount, and stir to mix evenly.

[0100] (4) Measure the pH value of the solution, which is 7.0.

[0101] (5) Fine filter with a 0.2 μm microporous membrane to check the clarity of the solution.

[0102] (6) According to the measurement results, fill the liquid medicine into a vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com