Method for manufacturing golf club head

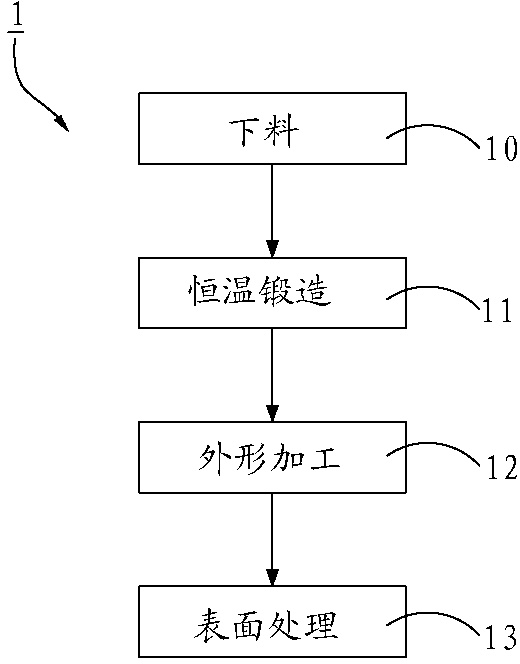

A golf club head and manufacturing method technology, applied to golf balls, golf clubs, rackets, etc., can solve the problems of difficult dimensional precision control, wear and tear, increased manufacturing costs, etc., to save processing operations and costs, and reduce wear and tear rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

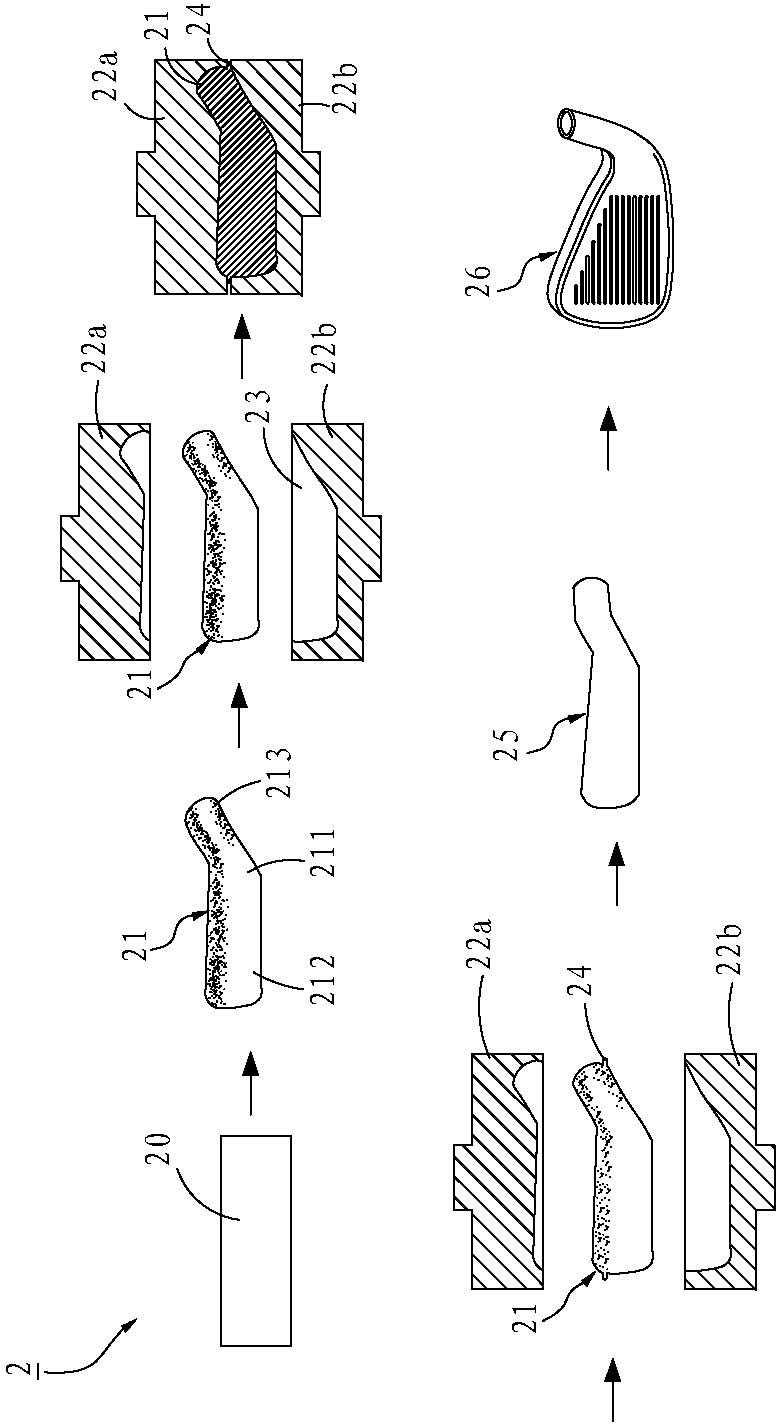

[0030] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

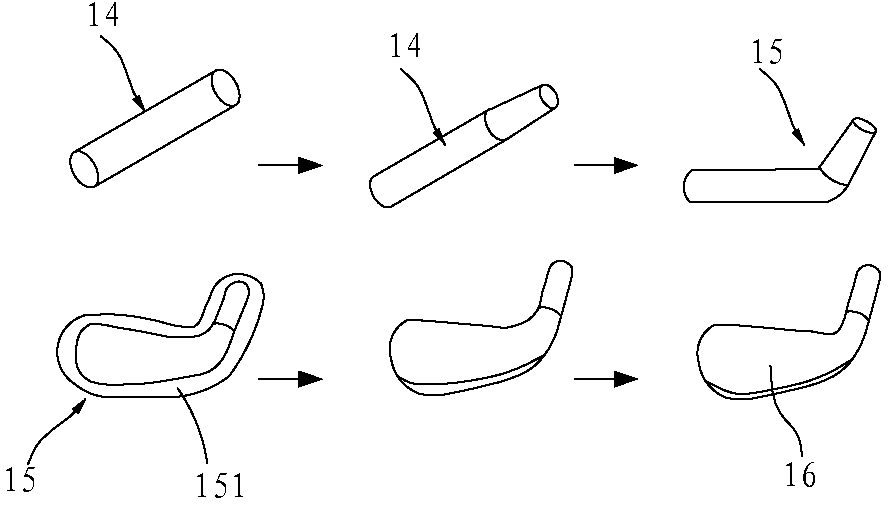

[0031] refer to Figure 4 , a preferred embodiment of the golf club head manufacturing method 3 of the present invention, which sequentially includes a cutting step 31, a bending forming step 32, and a forging step 33; wherein, in the cutting step 31, it is prepared in advance Place a base material 5, utilize a punching die (not shown in the figure) to be cut into shape according to required size, and in the present embodiment, the width of the two ends 5a, 5b of this base material 5 gained after cutting can be To be different, and to match the size of a golf club body (not shown), one end 5a of the base material 5 can be tapered, as shown in the figure, so that the base material 5 The widths of the two ends 5b, 5a are large and small; moreover, in the bending and forming step 32, the base material 5 is bent a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com