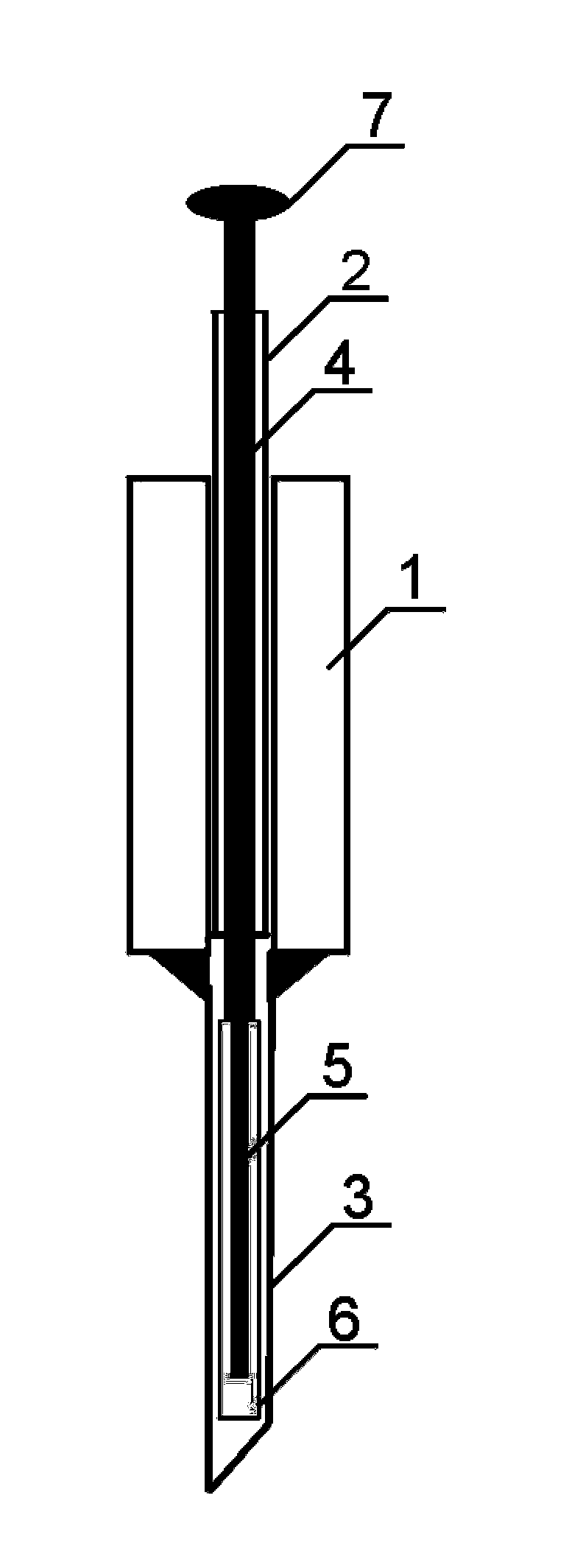

Preparation of solid-phase microextraction (SPME) fiber and extraction device assembled by same

A technology for extracting fibers and extraction devices, applied in the field of solid-phase microextraction, to achieve the effects of overcoming poor mechanical strength, novel structure, and unique design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation of solid-phase microextraction fiber coating, using covalent bond and method to prepare metal organic framework (MOFs) material ZIF-90 as the extraction fiber coating, the steps are as follows:

[0026] 1) Pretreatment of hollow quartz fiber:

[0027] Burn a hollow quartz fiber with an inner diameter of 250 μm and a length of 3 cm with an alcohol lamp to burn off the outer polyimide protective layer, put it in a sodium hydroxide solution with a concentration of 1M for activation, and expose a large amount of silicon hydroxyl groups on the surface, and then Wash with water until neutral, dry for later use;

[0028] 2) APTES functionalization of hollow silica fibers:

[0029] Put the hollow quartz fiber treated in the first step in the solution of APTES for reaction, react at room temperature for 12 hours, take it out and put it in a 120-degree oven for 30 minutes, repeat this process twice, finally wash with toluene and ethanol, and dry it for later use; ...

Embodiment 2

[0033] A preparation of solid-phase microextraction fiber coating, using covalent bond and method to prepare metal organic framework (MOFs) material ZIF-8 as the extraction fiber coating, the steps are as follows:

[0034] 1) Same as embodiment 1;

[0035] 2) Same as embodiment 1;

[0036] 3) Preparation of silica fiber surface bonds and metal-organic framework materials:

[0037] Dissolve 0.12g of zinc nitrate tetrahydrate and 0.03g of 2-methyl-imidazole in 9mL of N,N-dimethylformamide, ultrasonically dissolve for 10min, and place the mixture in a 25mL polytetrafluoroethylene reactor; the second step Put the treated quartz fiber vertically into the reaction mixture, react at 140°C for 24 hours, wait for the reactor to cool down, take out the quartz fiber with surface bonds and metal-organic framework materials, and use N,N-dimethylformamide solvent After washing, the extracted fiber of solid phase microextraction is obtained.

Embodiment 3

[0039] A preparation of solid-phase microextraction fiber coating, using covalent bond and method to prepare metal organic framework (MOFs) material ZIF-7 as the extraction fiber coating, the steps are as follows:

[0040] 1) Same as embodiment 1;

[0041] 2) Same as embodiment 1;

[0042] 3) Preparation of silica fiber surface bonds and metal-organic framework materials:

[0043] Dissolve 0.28g of zinc nitrate tetrahydrate and 0.16g of benzimidazole in 15mL of N,N-dimethylformamide, ultrasonically dissolve for 10min, and place the mixture in a 25mL polytetrafluoroethylene reactor; process the second step Put the quartz fiber vertically into the reaction mixture, react at 130°C for 48 hours, wait for the reactor to cool down, take out the quartz fiber with surface bonds and metal-organic framework materials, wash with N,N-dimethylformamide solvent, That is the extraction fiber of solid phase microextraction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com