Control method and system for roller painting and printing production line

A control method and control system technology, applied in the general parts of printing machinery, printing, printing presses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

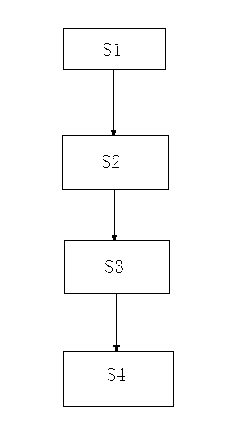

[0031] S1, input the roll diameter and the process speed of each roller in the first roller coating unit into the PLC control module, and the PLC control module calculates the theoretical roll surface linear velocity of each roll according to the process speed and the roll diameter of each roll (at first Calculate the theoretical rotational speed, theoretical rotational speed = process speed / Wu * roll diameter, and then calculate the theoretical roll surface linear speed according to the theoretical rotational speed, theoretical roll surface linear speed = theoretical rotational speed * roll diameter * Wu), so that the theoretical roll surface of each roll The line speed is consistent with the process speed, and the calculated theoretical roll surface line speed signals of each roll are respectively output to the servo control module with an encoder;

[0032] S2, the servo control module receives the theoretical roller surface speed signal of each roller from the PLC control ...

Embodiment 2

[0041] PLC control module, which stores the roller diameter and process speed data of each roller of the first roller coating unit, calculates the theoretical roller surface speed of each roller according to the process speed and the roller diameter of each roller, so that the theoretical roller surface speed of each roller Consistent with the process speed, and output the calculated theoretical roll surface speed signals of each roll respectively;

[0042] The servo control module has an encoder, the servo control module receives the theoretical roller surface speed signal from the PLC control module, and drives each roller according to the theoretical roller surface speed signal, and the encoder is used for Collect the actual roll surface speed of each roll, and output the actual roll surface speed signal of each roll to the PLC control module, so that the PLC control module adjusts the roll surface speed according to the actual roll surface speed signal and the theoretical r...

Embodiment 3

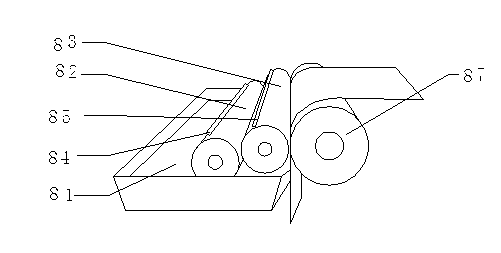

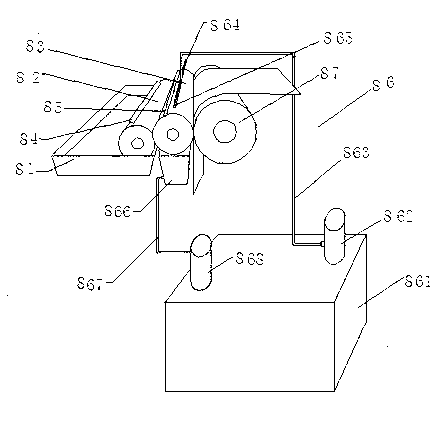

[0050] Further, in this embodiment, the first doctor blade 84 is in contact with the suction roller 82 at an angle less than 30 degrees; the second doctor blade 85 is in contact with the coating roller 83 at an angle greater than 30 degrees . Due to the different scraping positions of the suction roller 82 and the coating roller 83 at the same time, the first scraper 84 and the second scraper 85 are set to different angles, which can ensure that the suction roller 82 and the coating Scraping of roller 83.

[0051] In this embodiment, the roller coating equipment assembly 8 further includes a cleaning device 86, and the cleaning device 86 includes a liquid supply tank 861, a cleaning liquid delivery pump 862 for pumping the liquid supply tank 861, and the The cleaning liquid transmission pipe 863 communicated with the cleaning liquid transmission pump 862 and the spray pipe 864 communicated with the cleaning liquid transmission pipe. The spray pipe 864 is arranged above the ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com