Pentachlorocyclopropane preparation method

A technology of pentachlorocyclopropane and trichloropropene, which is applied in the field of preparation of pentachlorocyclopropane, and can solve problems such as high tension of three-membered rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

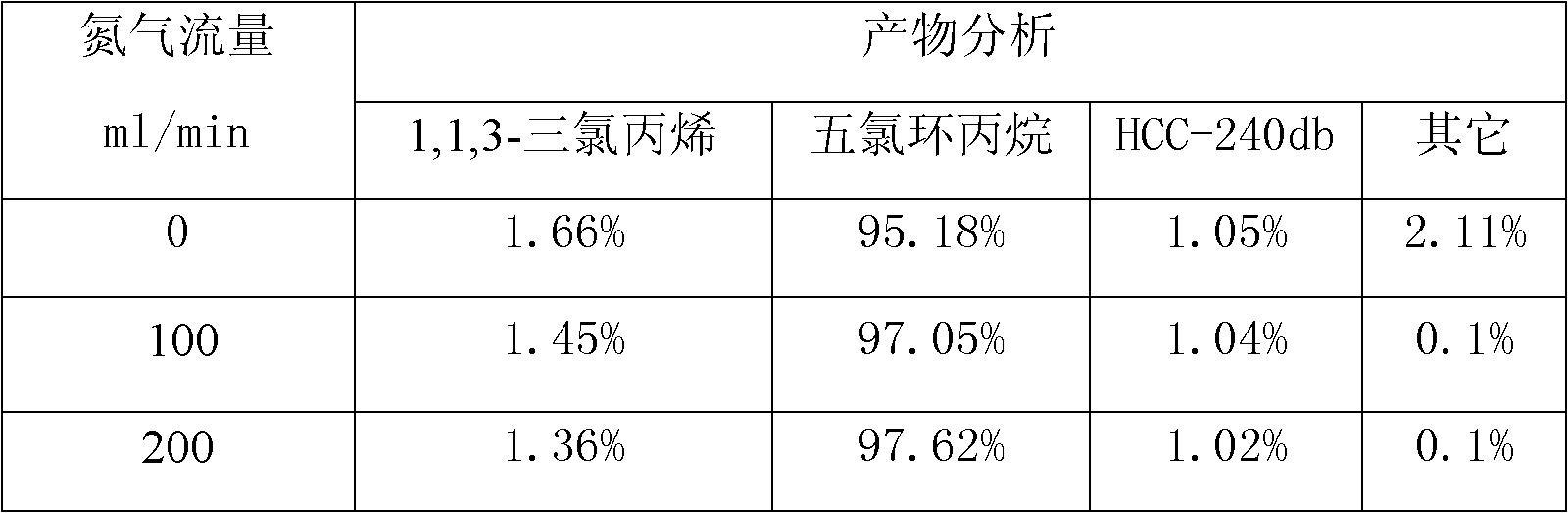

[0018] In a 1000ml three-neck flask, a reflux condenser is installed in the middle, chlorine gas is passed through one side, and a thermometer is installed on the other side, and 1000g of 1,1,3-trichloropropene, anhydrous FeCl 3 0.3 grams, chlorine gas flow rate 200ml / min, reaction time 12hr, the sample was treated with nitrogen gas for 20min before the reaction, without photocatalysis, the reaction results are shown in Table 1:

[0019] Table 1 Effect of nitrogen flow rate on the reaction

[0020]

Embodiment 2

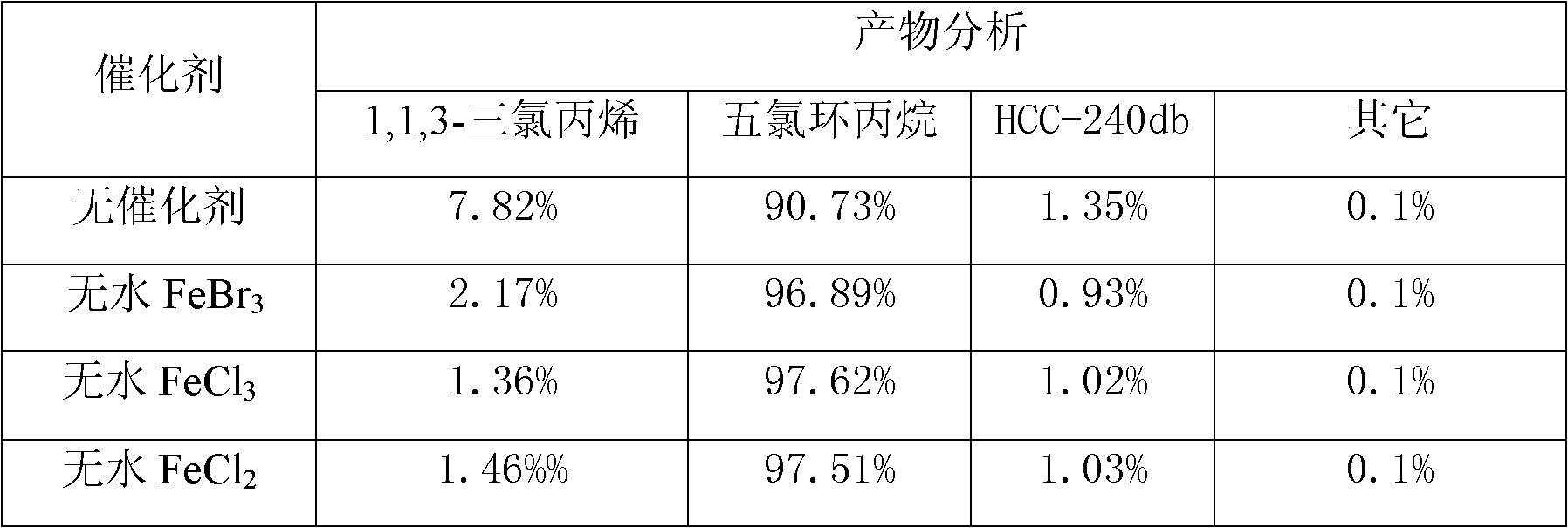

[0022] In a 1000ml three-neck flask, a reflux condenser is installed in the middle, chlorine gas is passed through one side, and a thermometer is installed on the other side, 1000g of 1,1,3-trichloropropene (water content 23ppm) is added, and anhydrous FeCl 3 , Anhydrous FeBr 3 , Anhydrous FeCl 2 0.3 grams each, chlorine gas flow rate 200ml / min, 200ml / min nitrogen gas treatment sample for 20min, reaction temperature 20±0.5℃, no photocatalysis, reaction time 12hr, reaction results are shown in Table 2:

[0023] Table 2 Effect of catalyst on reaction result

[0024]

Embodiment 3

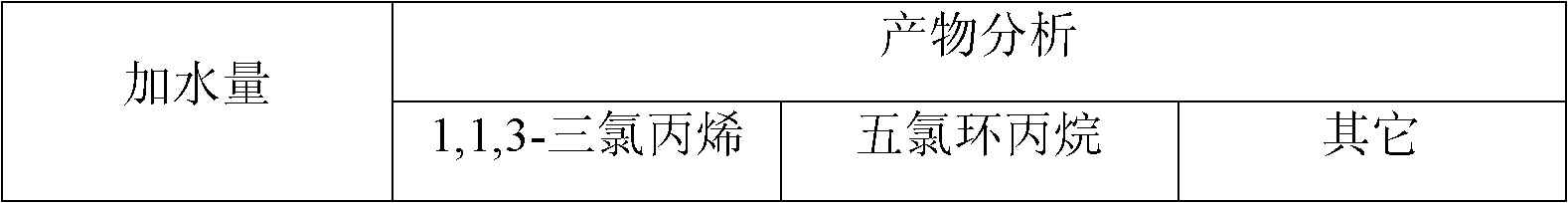

[0026] In a 1000ml three-neck flask, a reflux condenser is installed in the middle, chlorine gas is passed through one side, and a thermometer is installed on the other side, and 1000g of 1,1,3-trichloropropene, anhydrous FeCl 3 0.3 grams, chlorine gas flow rate 200ml / min, 200ml / min nitrogen gas treatment sample sample for 20min, reaction temperature 20±0.5℃, no photocatalysis, reaction time 12hr, reaction results are shown in Table 3:

[0027] Table 3 Effect of moisture on the reaction

[0028]

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com