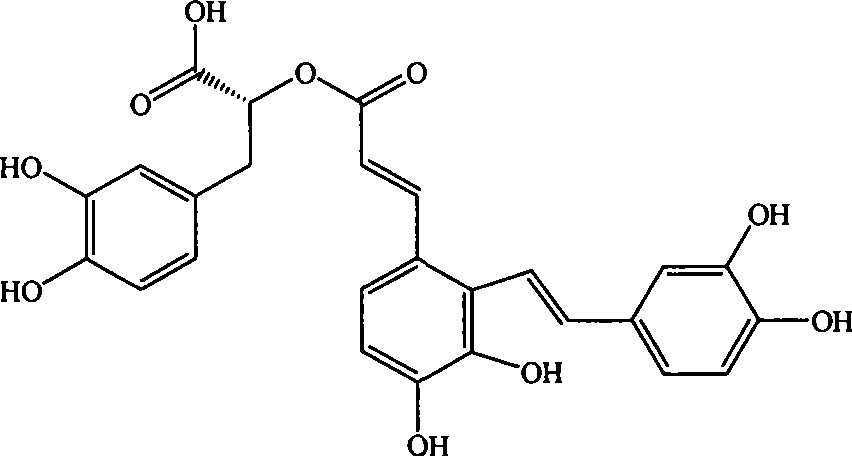

Method for purifying salvianolic acid A

A purification method and technology of salvianolic acid, applied in chemical instruments and methods, separation/purification of carboxylic acid esters, organic chemistry, etc., can solve problems such as high cost, many conversion by-products, serious organic solvent residues, etc., and achieve production The effect of low cost and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

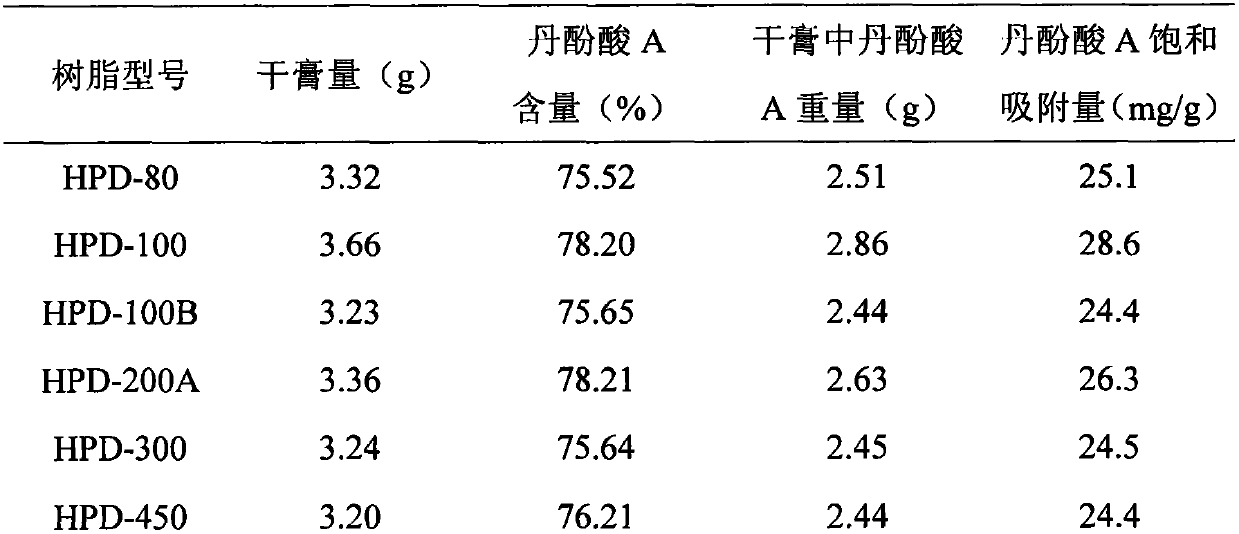

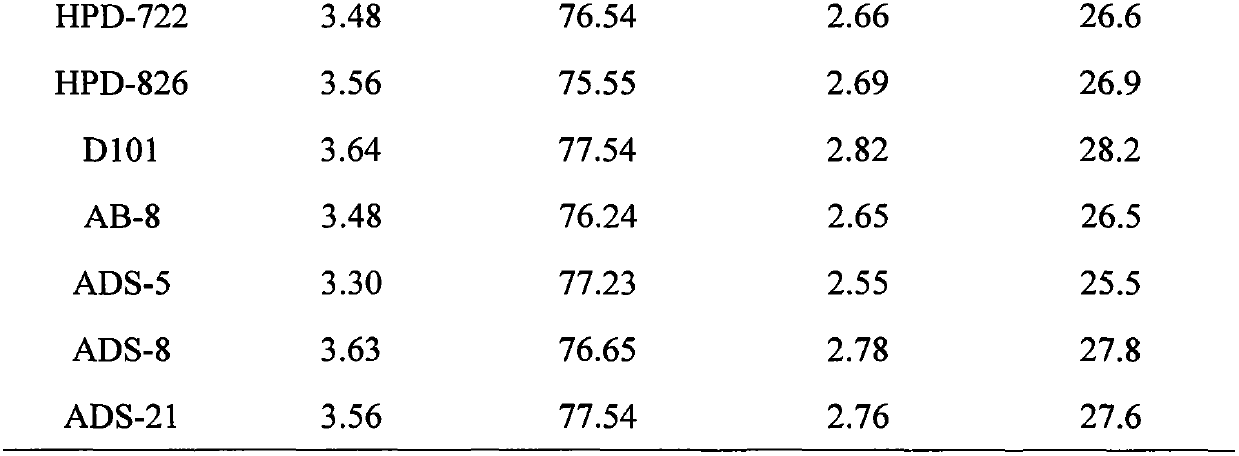

Embodiment 1

[0029] Adjust the pH value of the eluate or extract containing salvianolic acid A to 2.5 with 20% phosphoric acid, centrifuge, concentrate the supernatant under reduced pressure to contain 3 mg of salvianolic acid A per 1 ml, and perform HPD-100 macroporous resin column chromatography For separation, the ratio of the loading amount of salvianolic acid A to the macroporous adsorption resin is 1:50, and the diameter-to-height ratio of the resin column is 1:10, and eluted with 3 times column volume of water and 5 times column volume of 25% ethanol to remove impurities , then eluted with 4 times the column volume of 40% ethanol, detected by HPLC, collected the 40% ethanol eluted part containing salvianolic acid A, recovered the ethanol under reduced pressure and concentrated to no alcohol smell; the aqueous solution was concentrated to contain 5 mg salvianol per ml The solution of acid A is separated by polyamide chromatography column, the ratio of salvianolic acid A loading to pol...

Embodiment 2

[0031]Adjust the pH value of the eluate or extract containing salvianolic acid A to 2.5 with 15% hydrochloric acid, centrifuge, concentrate the supernatant under reduced pressure to contain 5 mg of salvianolic acid A per 1 ml, and perform HPD-100 macroporous resin column chromatography For separation, the ratio of the loading amount of salvianolic acid A to the macroporous adsorption resin was 1:45, and the diameter-to-height ratio of the resin column was 1:8, and eluted with 3.5 times column volume of water and 4 times column volume of 25% ethanol to remove impurities , then eluted with 5 times column volume of 45% ethanol, detected by HPLC, collected the 45% ethanol eluted part containing salvianolic acid A, recovered the ethanol under reduced pressure and concentrated to no alcohol smell; the aqueous solution was concentrated to contain 5 mg salvianol per ml The solution of acid A is separated by polyamide chromatography column, the ratio of salvianolic acid A loading to pol...

Embodiment 3

[0033] Adjust the pH value of the eluate or extract containing salvianolic acid A to 2.8 with 15% nitric acid, centrifuge, concentrate the supernatant under reduced pressure to contain 6 mg of salvianolic acid A per 1 ml, and perform HPD-100B macroporous resin column chromatography For separation, the ratio of the loading amount of salvianolic acid A to the macroporous adsorption resin was 1:40, and the ratio of diameter to height of the resin column was 1:7, and eluted with 4 times column volume of water and 4 times column volume of 25% ethanol respectively to remove impurities , then eluted with 5 times column volume of 40% ethanol, detected by HPLC, collected the 40% ethanol eluted part containing salvianolic acid A, recovered the ethanol under reduced pressure and concentrated to no alcohol smell; the aqueous solution was concentrated to contain 6 mg salvianol per ml The solution of acid A is separated by polyamide chromatography column, the ratio of salvianolic acid A load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com