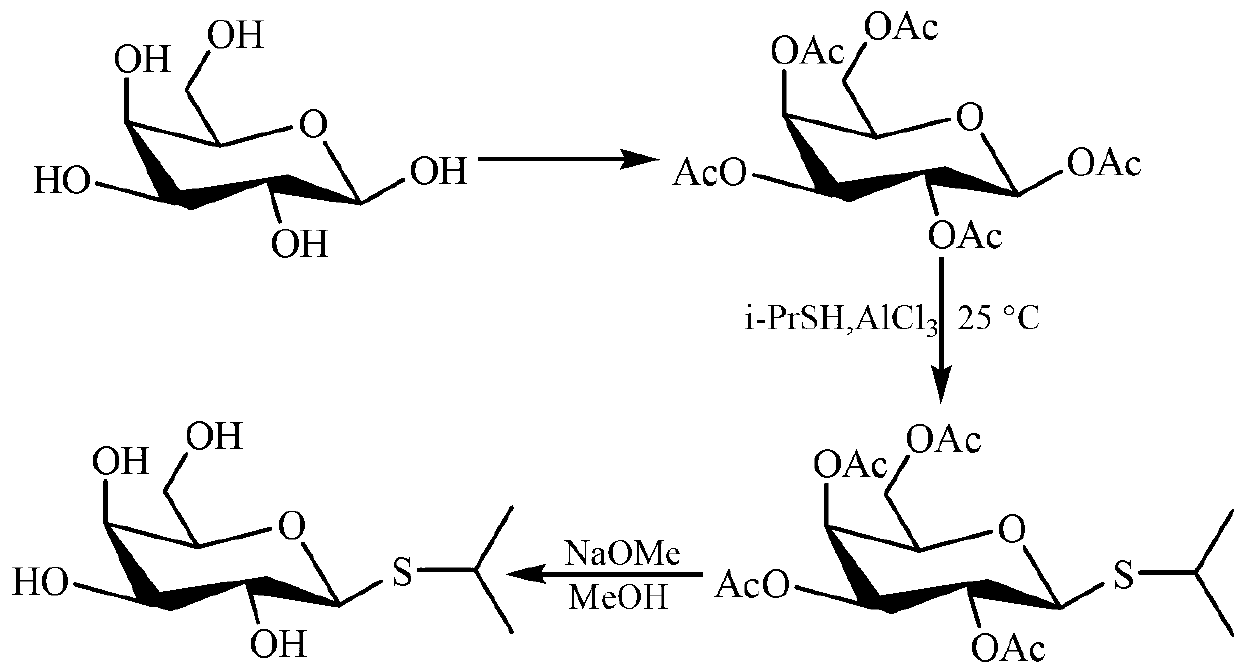

Method for synthesizing isopropyl-beta-D-thiogalactoside

A technology of thiogalactoside and thiogalactoside, which is applied in the field of synthesis of isopropyl-β-D-thiogalactoside, can solve the problems of fire-prone handling workload and environmental burden, and achieve process safety The effect of convenience and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1 Preparation of isopropyl-β-D-thiogalactoside

[0015] Preparation of penta-O-acetyl-β-D-galactose

[0016] 1. Add 125 ml of acetic anhydride and 20 g of anhydrous sodium acetate into a 500 ml reaction flask, slowly heat to reflux to dissolve the solid completely, and then carefully add 25 g of D-galactose in batches. After the addition was complete, the reaction mixture was refluxed for an additional 120 minutes. Afterwards, the reaction solution was poured into 300 ml ice-water mixture and stirred vigorously for 30 minutes, and a khaki solid precipitated out. Filter, wash the filter cake with water 2-3 times, and dry below 70°C. The obtained 37.9 g of penta-O-acetyl-β-D-galactose was recrystallized with ethanol as a solvent, and dried to obtain 31.1 g of pure penta-O-acetyl-β-D-galactose as a colorless solid , the yield is about 57%.

[0017] 2. Add 150 ml of acetic anhydride and 20 g of anhydrous sodium acetate into a 500 ml reaction flask, slowly heat t...

Embodiment 2

[0023] Example 2 Preparation of isopropyl-β-D-thiogalactoside

[0024] Preparation of penta-O-acetyl-β-D-galactose

[0025]1. Add 125 ml of acetic anhydride and 20 g of anhydrous sodium acetate into a 500 ml reaction flask, slowly heat to reflux to dissolve the solid completely, and then carefully add 25 g of D-galactose in batches. After the addition was complete, the reaction mixture was refluxed for an additional 140 minutes. Afterwards, the reaction solution was poured into 300 ml ice-water mixture and stirred vigorously for 35 minutes, and a khaki solid precipitated out. Filter, wash the filter cake with water 2-3 times, and dry below 70°C. The obtained 37.9 g of penta-O-acetyl-β-D-galactose was recrystallized with ethanol as a solvent, and dried to obtain 31.1 g of pure penta-O-acetyl-β-D-galactose as a colorless solid , the yield is about 58%.

[0026] 2. Add 150 ml of acetic anhydride and 20 g of anhydrous sodium acetate into a 500 ml reaction flask, slowly heat to...

Embodiment 3

[0032] Example 3 Preparation of isopropyl-β-D-thiogalactoside

[0033] Preparation of penta-O-acetyl-β-D-galactose

[0034] 1. Add 125 ml of acetic anhydride and 20 g of anhydrous sodium acetate into a 500 ml reaction flask, slowly heat to reflux to dissolve the solid completely, and then carefully add 25 g of D-galactose in batches. After the addition was complete, the reaction mixture was refluxed for an additional 120 minutes. Afterwards, the reaction solution was poured into 300 ml ice-water mixture and stirred vigorously for 30 minutes, and a khaki solid precipitated out. Filter, wash the filter cake with water 2-3 times, and dry below 70°C. The obtained 37.9 g of penta-O-acetyl-β-D-galactose was recrystallized with ethanol as a solvent, and dried to obtain 31.1 g of pure penta-O-acetyl-β-D-galactose as a colorless solid , the yield is about 57%.

[0035] 2. Add 150 ml of acetic anhydride and 20 g of anhydrous sodium acetate into a 500 ml reaction flask, slowly heat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com