Low-rank coal quality-improving method and equipment

A technology for upgrading equipment and low-rank coal, which is applied in the petroleum industry, coke cooling, coke ovens, etc., can solve the operating conditions and engineering scale-up of lignite semi-coke passivation process. And commercial promotion is limited, the scale of formation and control cannot be verified, etc., to achieve the effect of high strength, convenient deep processing, and large added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

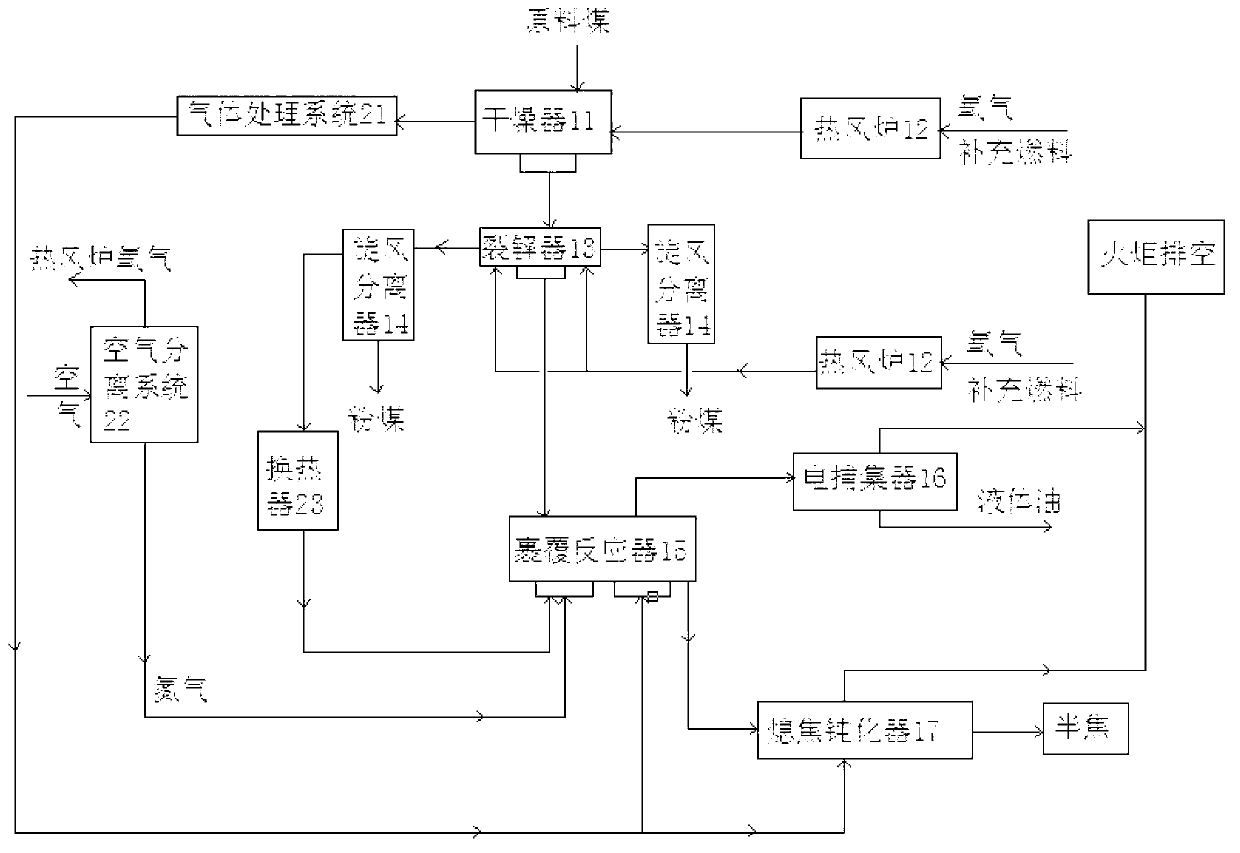

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. In this embodiment, taking lignite as an example, a low-rank coal upgrading method and its equipment are disclosed.

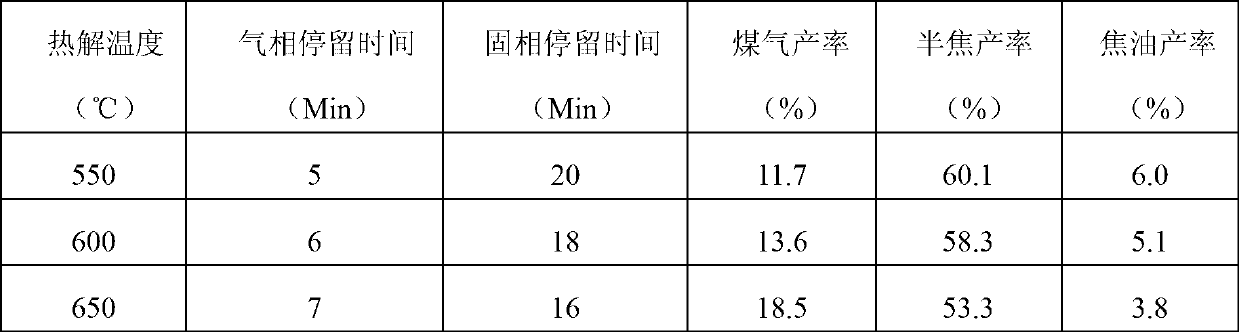

[0041] Such as figure 1 As shown, lignite as a raw material enters the drier 11 through the feeding pipeline, and at the same time, the hot stove 12 supplies the gas heat carrier to the drier 11, and the gas heat carrier heats the lignite in the drier 11. Wherein, the hot blast stove 12 uses oxygen and fuel oil as supplementary fuel, natural gas or liquefied gas, etc. as raw materials, and oxygen reacts with supplementary fuel to generate CO 2 and gaseous H 2 Gas heat carrier with O as the main component, such as CO 2 The volume percentage is about 50%, gaseous H 2 The volume percentage of O is about 50%, and heat is released during the reaction to obtain a gas heat carrier with a suitable temperature. In this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com