Continuous charging silicon single crystal furnace

A technology of silicon single crystal and hopper, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problem of inconsistent overall concentration of crystal rods, achieve the effect of reducing production costs and ensuring the overall concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

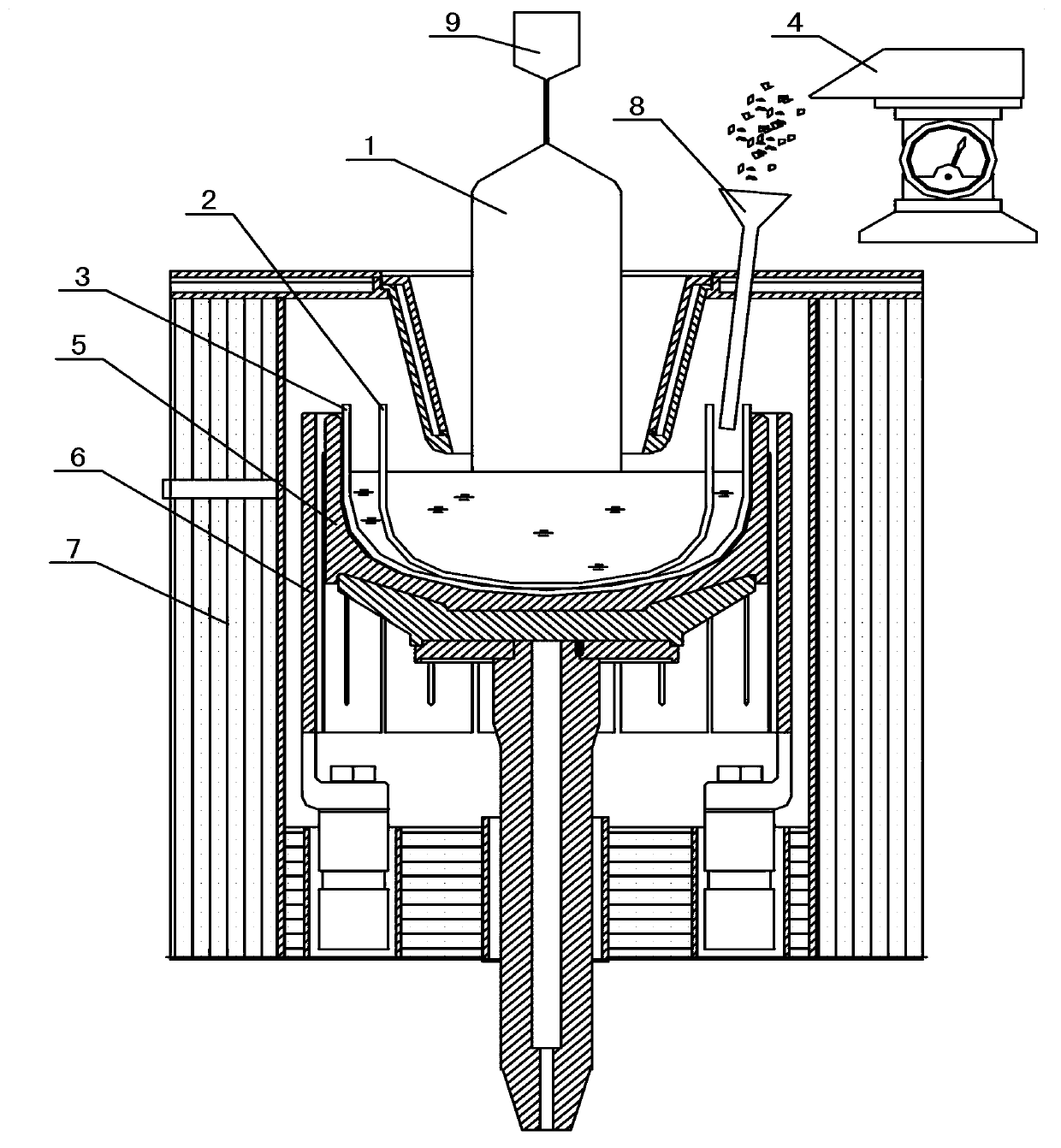

[0018] like figure 1 Shown, is the concrete implementation structure schematic diagram of the present invention, among the figure:

[0019] The crystal rod 1 is placed in a single crystal furnace, the upper end of the crystal rod 1 is connected with a pulling device 9, and the furnace body is provided with a quartz crucible and a graphite crucible 5, and the quartz crucible is set with double crucibles, including an inner crucible 2 and an outer crucible 3 outside it. , there is a feeding gap between the inner and outer crucibles, the bottoms of the inner and outer crucibles are connected together, and a connected hole is arranged at the bottom, a graphite heater 6 is arranged on the outside of the graphite crucible 5, and an insulating material 7 is wrapped on the outside of the heater. A feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com