Stainless pulse silt-removal water-distribution device of water circulation cooling tower

A technology of water circulation cooling and water distribution device, used in water shower coolers, heat exchange equipment, damage protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

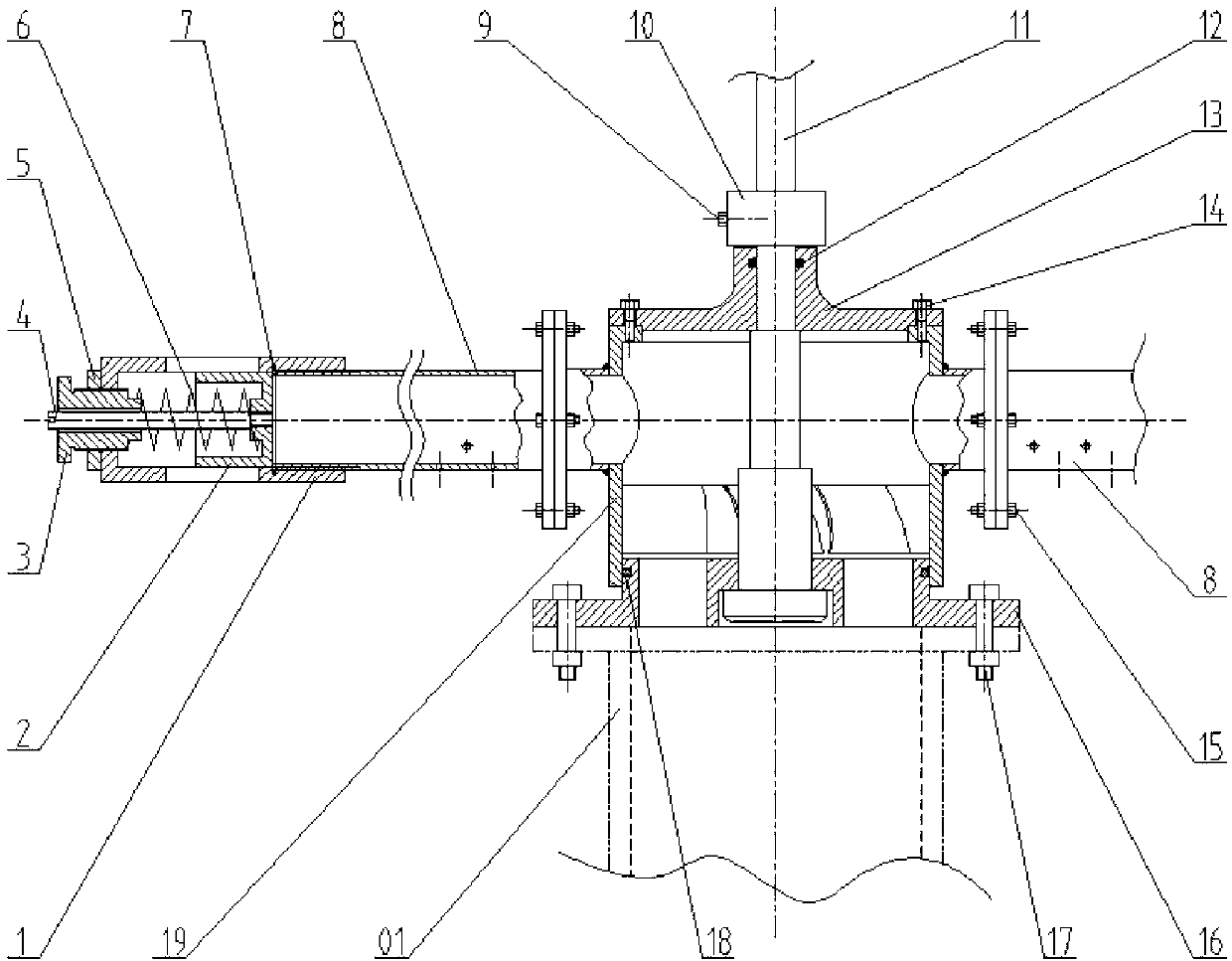

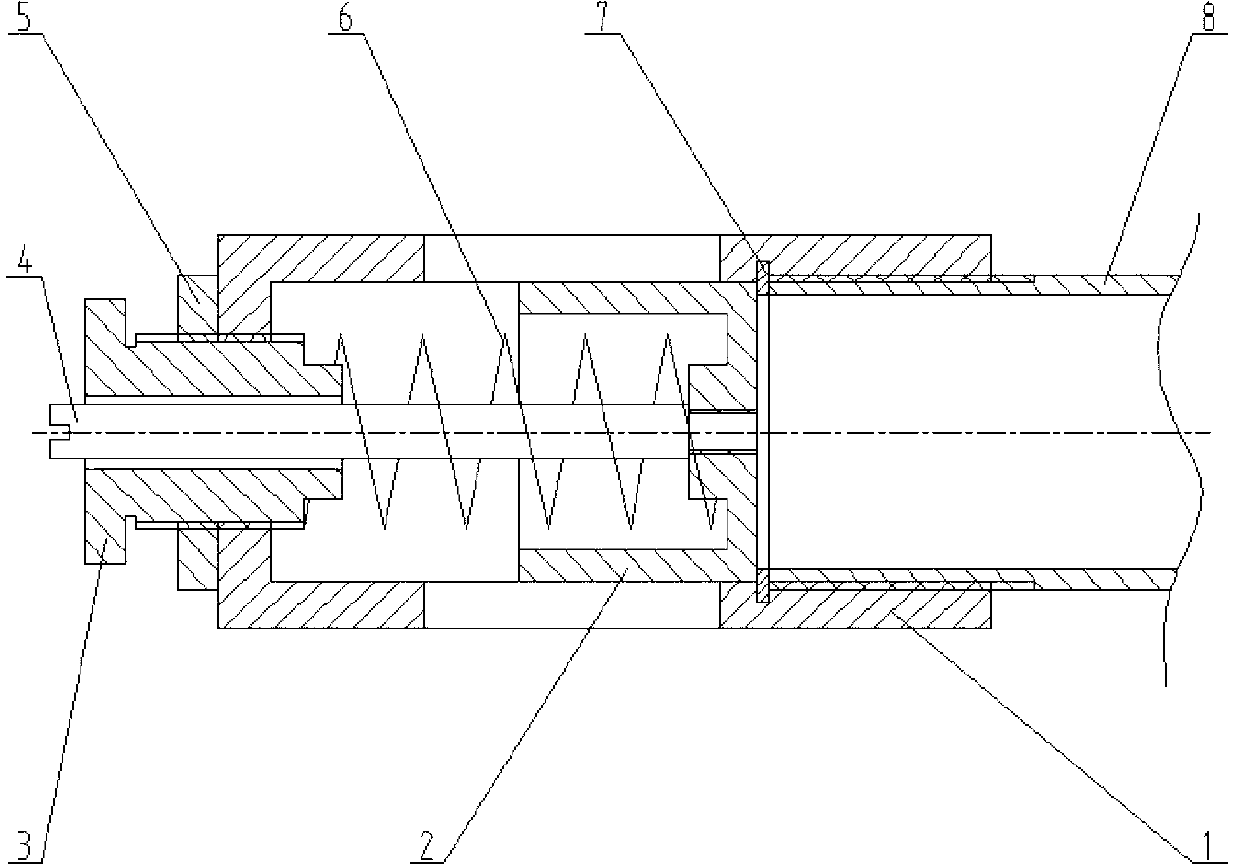

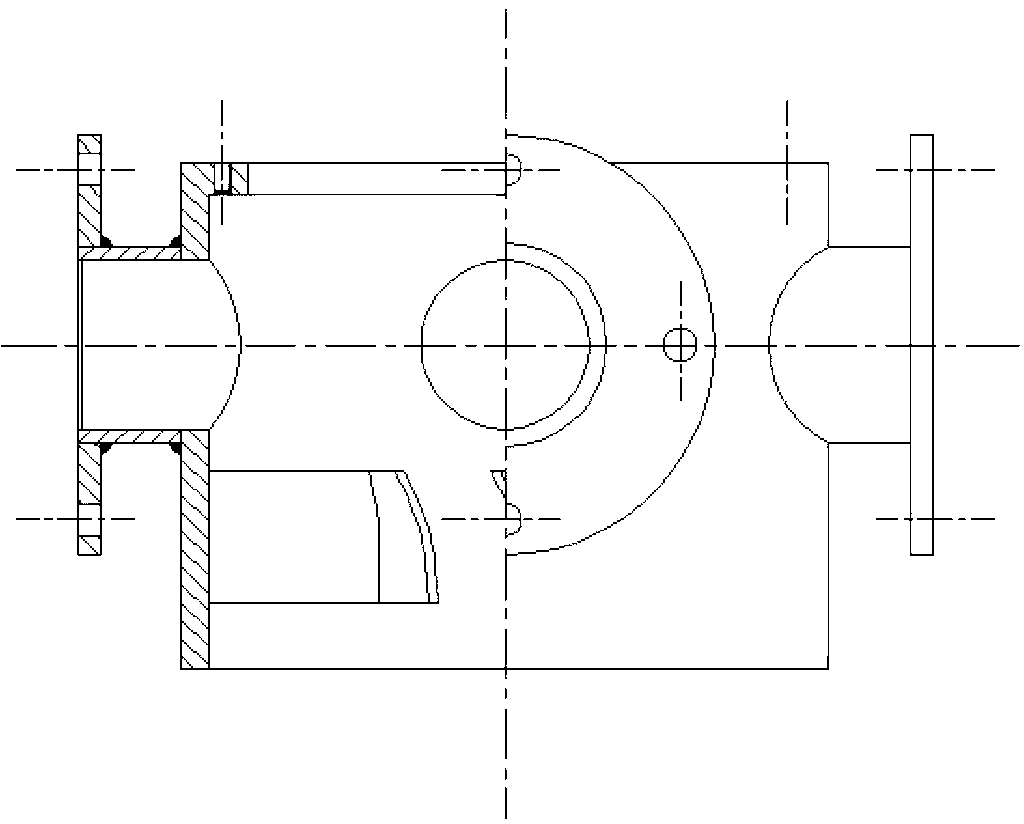

[0016] The invention is an effective method for solving fouling and silting in the water circulation cooling tower cloth water system. The center of the revolving body (19) is cylindrical, and the middle part of the cylinder wall is evenly distributed around the nozzle of the water distribution pipe (8). The number of nozzles in this embodiment is 4, and the nozzle is provided with a flange. Through the small bolt group ( 15) Connect with the flange of the water distribution pipe (8); the upper edge of the cylinder wall of the rotary body (19) is turned inward, and a threaded hole for connecting the upper cover (13) is provided at the flange; the inner side of the rotary body (19) is lower The rotating blades are evenly distributed, and the water flow of the water inlet pipe (01) impacts the blades to make the rotator (19) rotate, and the inner diameter of the cylinder wall below the blades is matched with the outer circle of the step of the base (16). The upper cover (13) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com