Determination method of silicon dioxide, silicon and silicon carbide in waste mortar from silicon wafer cutting

A silicon dioxide and silicon wafer cutting technology, which is applied in the measurement of color/spectral characteristics, weighing by removing certain components, etc., can solve the problems of high operation requirements, expensive platinum crucible, and inability to meet the requirements of silicon dioxide determination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] 1. Main instrument and equipment used in the present invention:

[0034] 1. Model 1752 UV-Vis spectrophotometer;

[0035] 1.2 constant temperature water bath;

[0036] 1.3 Vacuum drying oven.

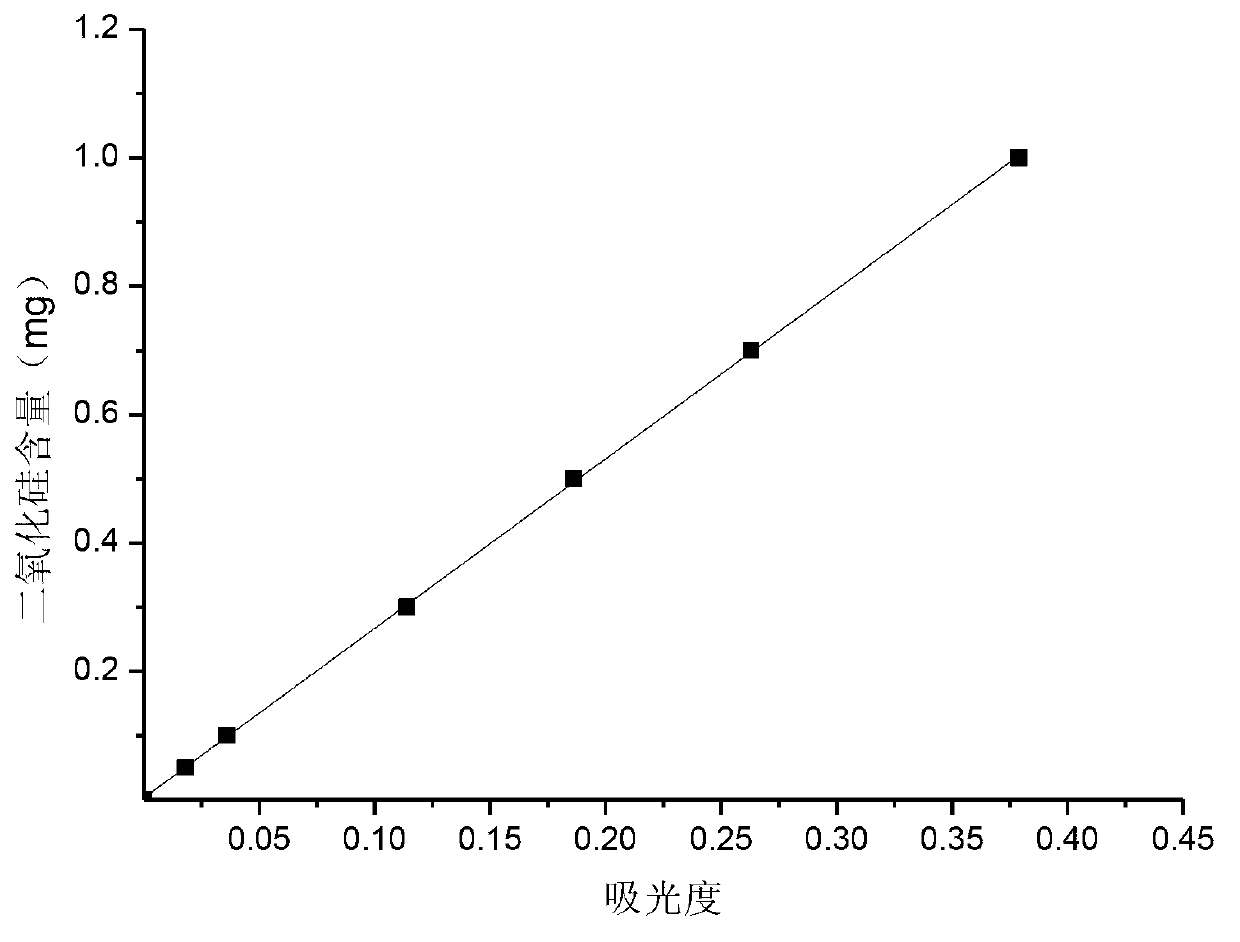

[0037] 2. The drafting of reagent used in the present invention and standard curve:

[0038] 2.1 Potassium chloride solution (10%)

[0039] 2.2 Hydrochloric acid: add 1 volume of hydrochloric acid to 1 volume of water

[0040] 2.3 Hydrofluoric acid: add 1 volume of hydrofluoric acid to 1 volume of water

[0041] 2.4 Aluminum chloride solution (45%): Dissolve 45g of aluminum chloride (hexahydrate) in water and dilute to 200mL

[0042] 2.5 p-nitrophenol solution (0.2%)

[0043] 2.6 Ammonia: Add 1 volume of ammonia to 4 volumes of water

[0044] 2.7 Hydrochloric acid: Add 1 volume of hydrochloric acid to 4 volumes of water

[0045] 2.8 Ammonium molybdate solution (8%): Dissolve 8g ammonium molybdate in water (stir and heat slightly), dilute to 100mL

[0046] 2.9 Tartaric ac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap