Novel nanosheet film for sensor and preparation method thereof

A technology of nanosheets and sensors, which is applied in the field of new nanosheet films and their preparation, can solve the problems of gas-sensing properties that have not been reported, and achieve the effects of low production cost, uniform thickness, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

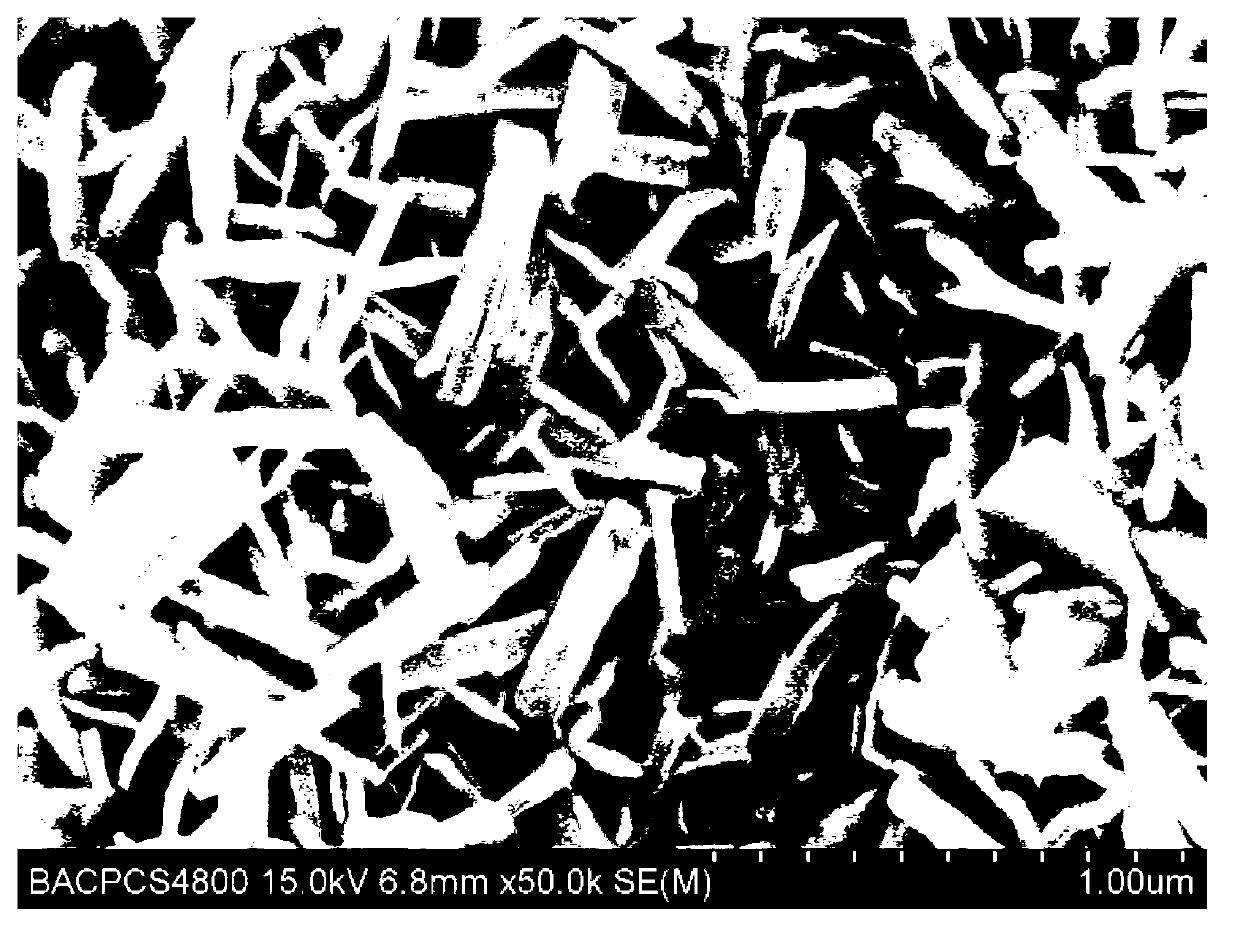

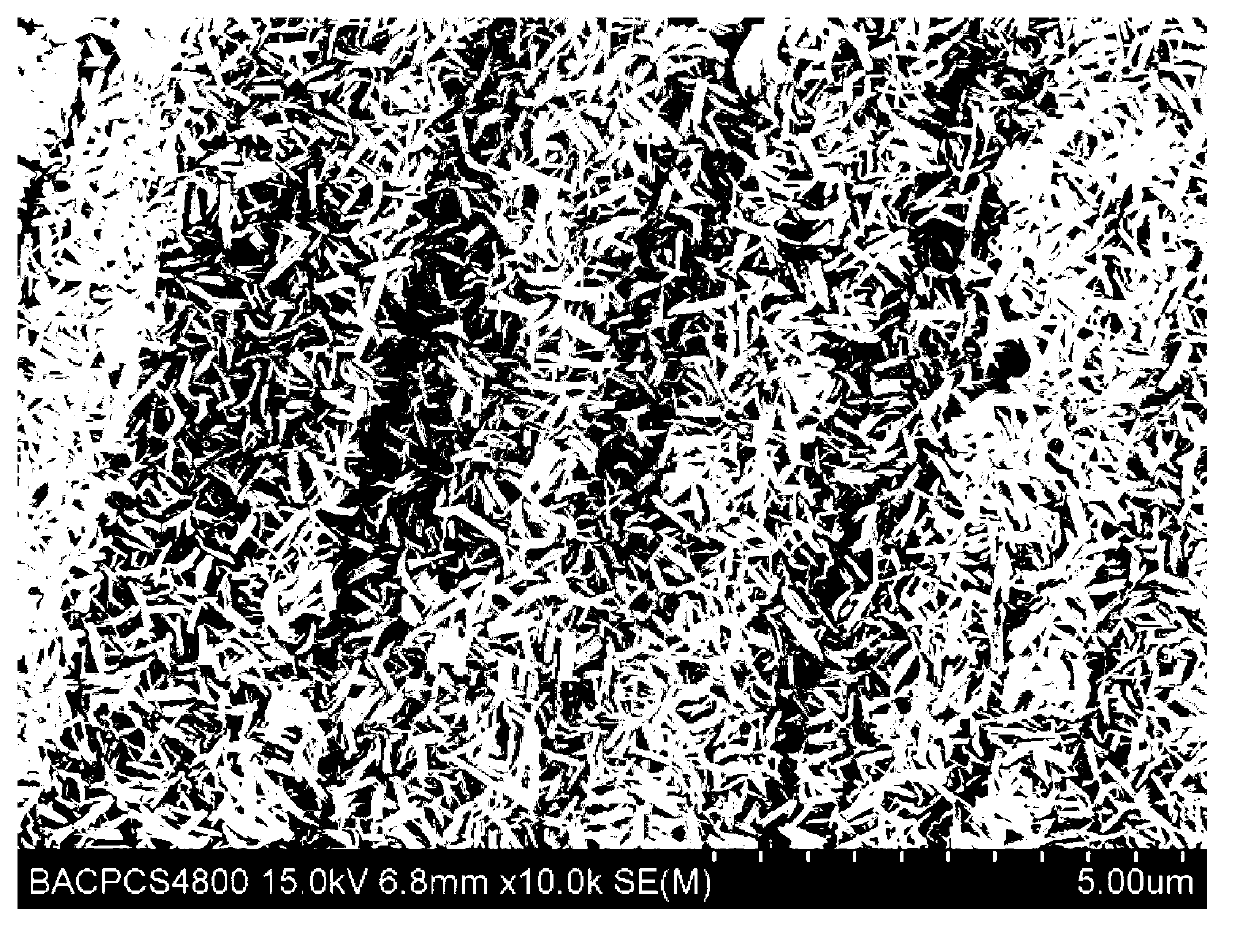

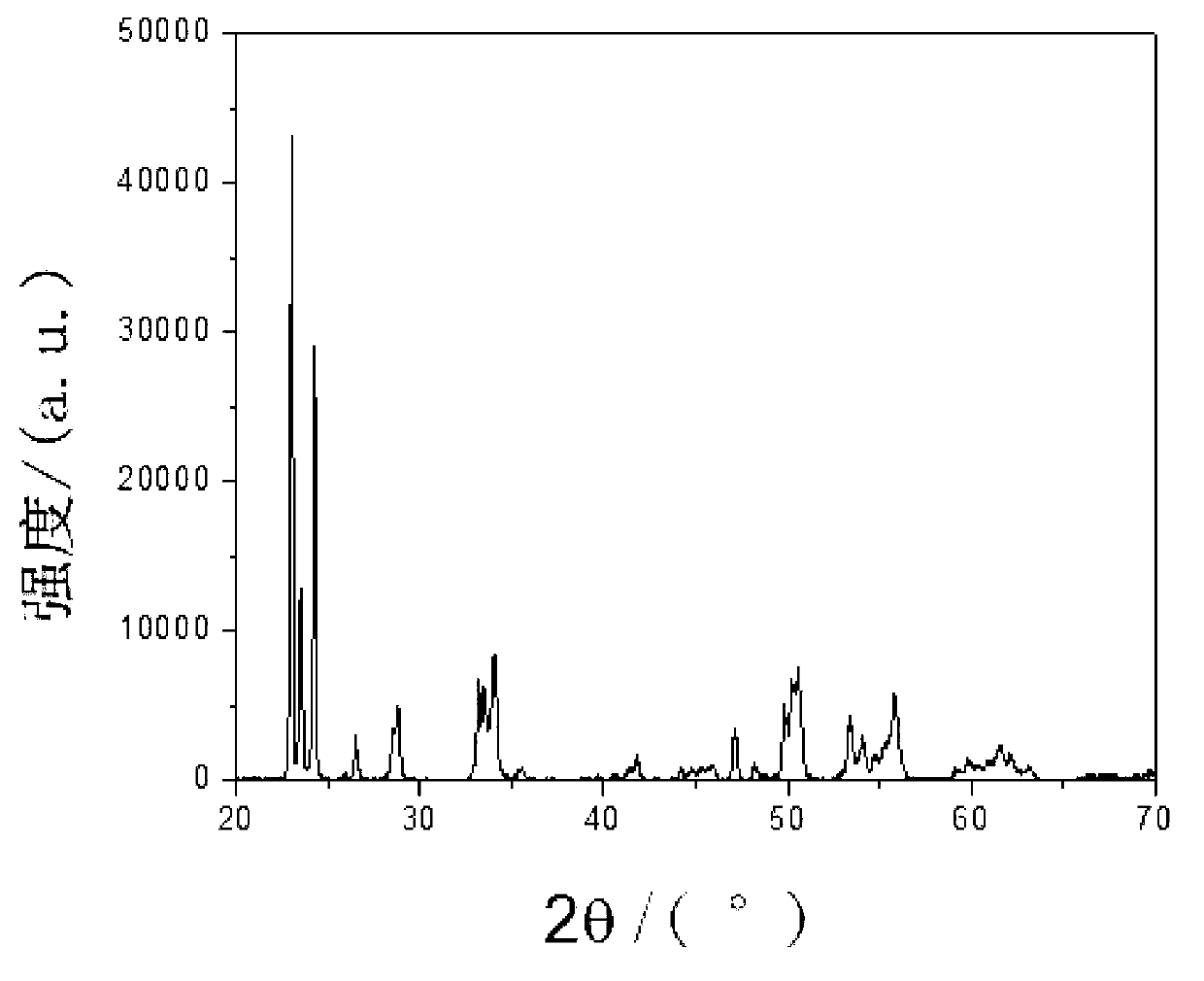

[0029] The preparation steps of the tungsten oxide nanosheet thin film with metal tungsten sheet as the reaction matrix are as follows:

[0030] The first step is to cut the pure tungsten sheet into a size of 15 mm×15 mm, carefully polish it with 500#, 1000#, 2000# sandpaper, and then ultrasonically clean it with acetone and deionized water for 10 minutes each.

[0031] The second step uses analytically pure Na 2 WO 4 2H 2 O, FeSO 4 ·7H 2 O and (NH 4 ) 2 C 4 h 4 o 6 Prepare an electrolyte solution containing tungsten and iron ions, in which Na 2 WO 4 2H 2 O, FeSO 4 ·7H 2 O and (NH 4 ) 2 C 4 h 4 o 6 The concentrations were 0.25 mol / L, 0.02 mol / L and 0.25 mol / L in turn, and the pH value of the electrolyte was adjusted to 4 with sulfuric acid, and the electrolyte was prepared with deionized water.

[0032] The third step is to put the prepared electrolyte into a beaker, place it in a water bath, connect the cathode to the substrate pretreated in step 1, and con...

Embodiment 2

[0041] The preparation steps of the molybdenum oxide nanosheet thin film with metal copper sheet as the reaction matrix are as follows:

[0042] The first step is to cut the copper sheet into 15 mm×15 mm, and sand it with 500#, 1000#, 2000# sandpaper before deposition, and ultrasonically clean it with acetone and deionized water.

[0043] The second step to analyze pure Na 2 MoO 4 2H 2 O, FeSO 4 ·7H 2 O and (NH4) 2 C 4 h 4 o 6 Prepare an electrolyte solution containing molybdenum and iron ions, in which Na 2 MoO 4 2H 2 O, FeSO 4 ·7H 2 O and (NH4) 2 C 4 h 4 o 6 The concentrations were 0.15 mol / L, 0.03 mol / L and 0.3 mol / L respectively, and the pH value of the electrolyte was adjusted to 5.5, and the electrolyte was prepared with deionized water.

[0044] The third step is to put the prepared electrolyte into a beaker, place it in a water bath, connect the cathode to the substrate pretreated in step 1, and connect the anode to the graphite sheet. Start the water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com