Remote intelligent maintaining device of transformer substation storage battery

An intelligent maintenance, battery technology, applied in the direction of secondary battery repair/maintenance, measuring device, measuring electricity, etc., can solve the problem of difficult quantitative testing and maintenance of batteries, difficult to regularly check capacity testing of batteries, and poor real-time data collection. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

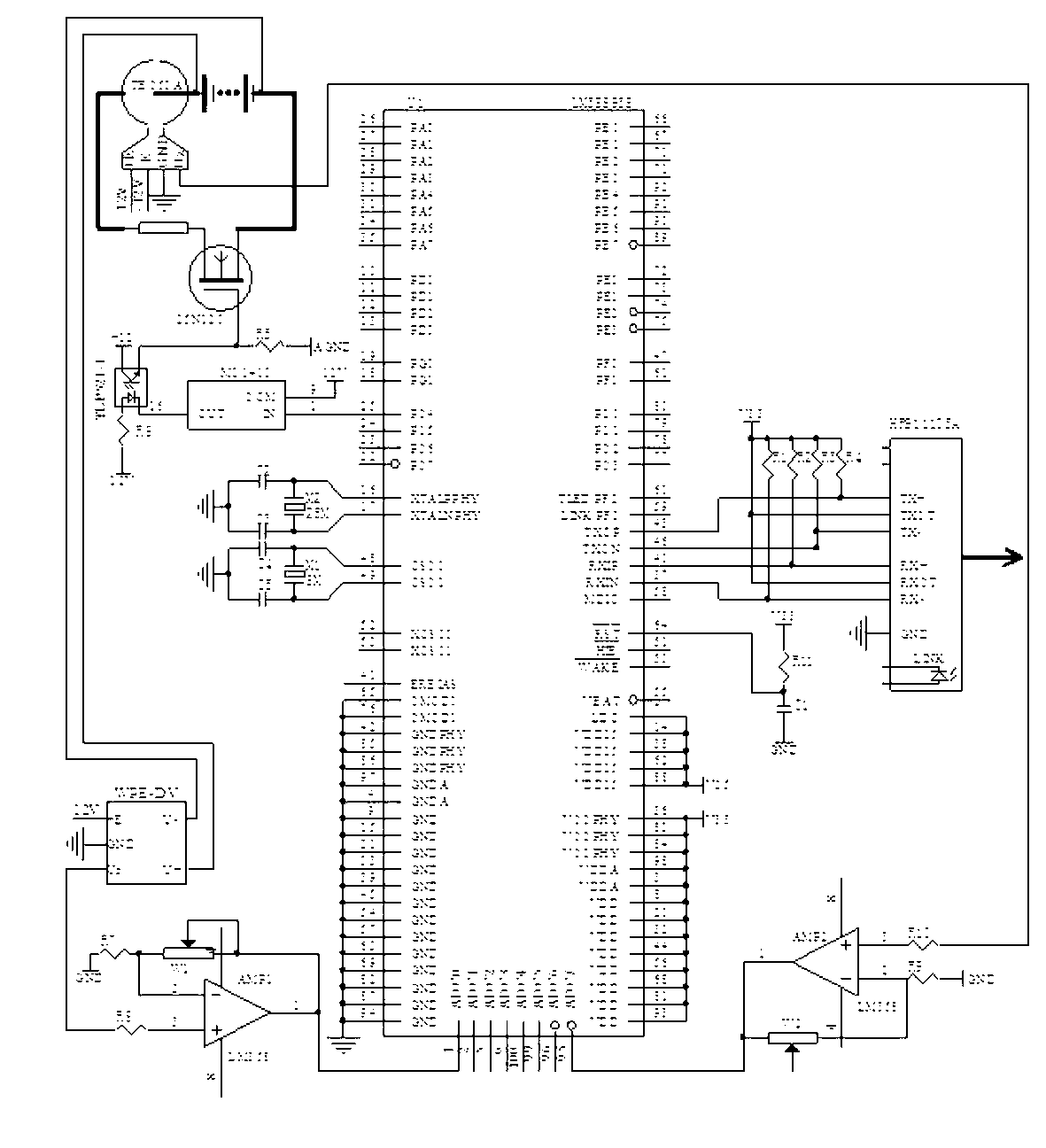

[0016] The remote intelligent storage battery maintenance device of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation methods.

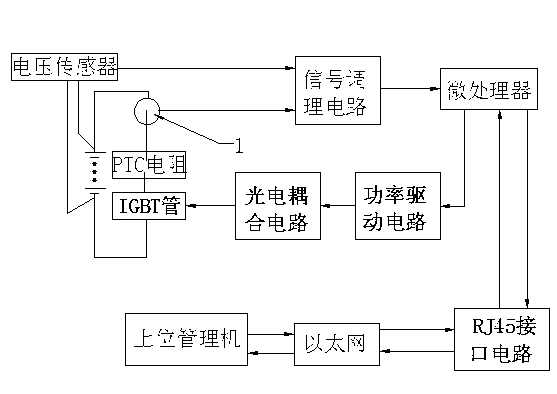

[0017] Such as figure 1 As shown, the battery remote intelligent maintenance device of the present invention includes an upper management machine and a microprocessor, a voltage sensor, a current sensor (1), a signal conditioning circuit, a power drive circuit, a photoelectric coupling circuit, an IGBT tube, an RJ45 interface circuit and Five loops formed by PTC resistors;

[0018] Wherein, it should be further explained that the upper management machine of the present invention is a computer installed with battery capacity testing and monitoring software compiled by VC language, which is connected to the Ethernet and controls the five major circuits through the Ethernet. More specifically, the upper management computer designs a special application program for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com