An impact type lithium thermal battery assembly for bombs

A thermal battery and impact-type technology, applied in the direction of delayed action cells, etc., can solve the problems that the turning process is more complicated than the punching process, the fixed fire cap part occupies a large height, and affects the reliable operation of electronic components, etc., to achieve reduction Dissipate heat, ensure time consistency, and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

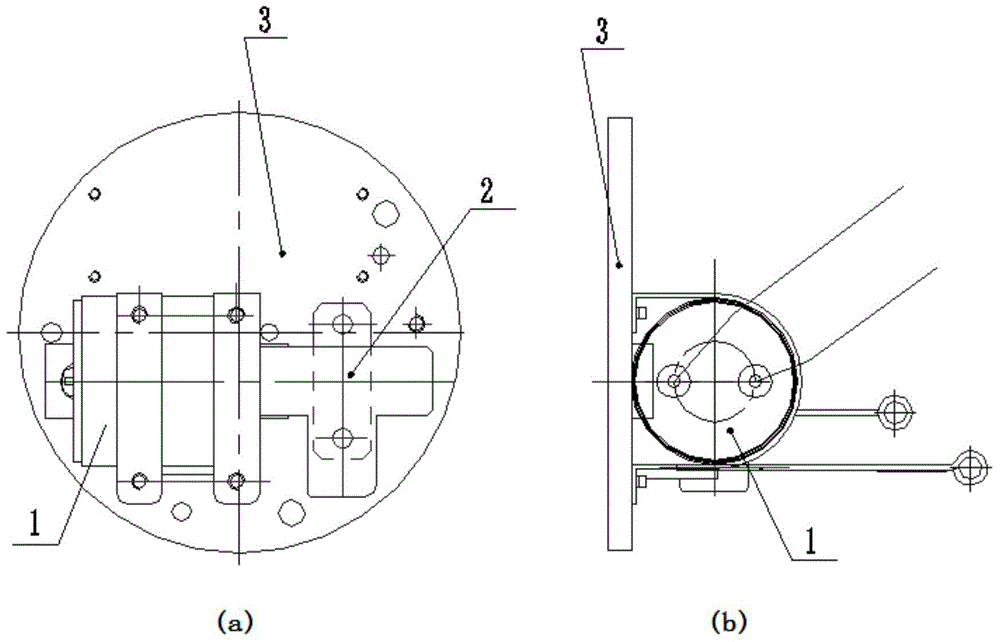

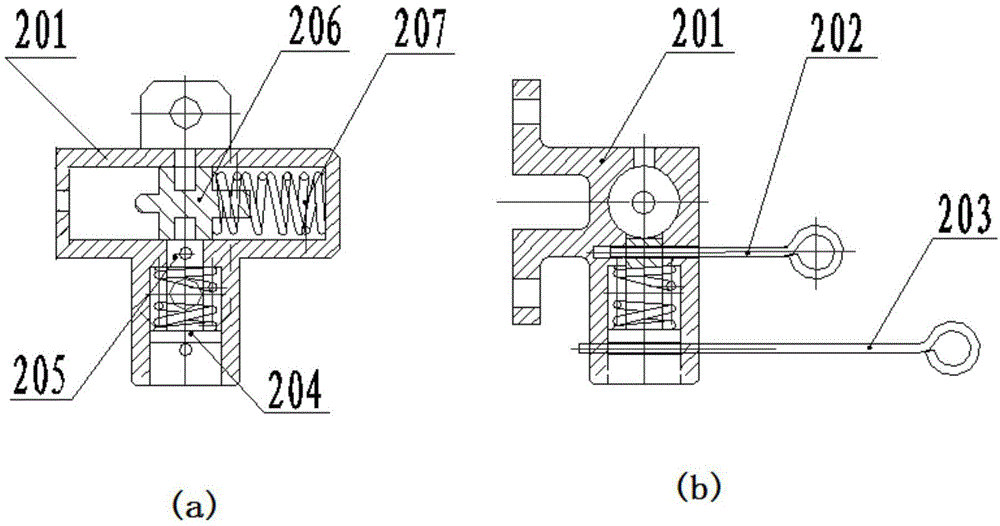

[0026] see Figure 1 to Figure 5 , the present embodiment provides a structure of an impact lithium thermal battery assembly for bombs, which is composed of a thermal battery 1, a firing mechanism 2 and an outer structure 3, wherein:

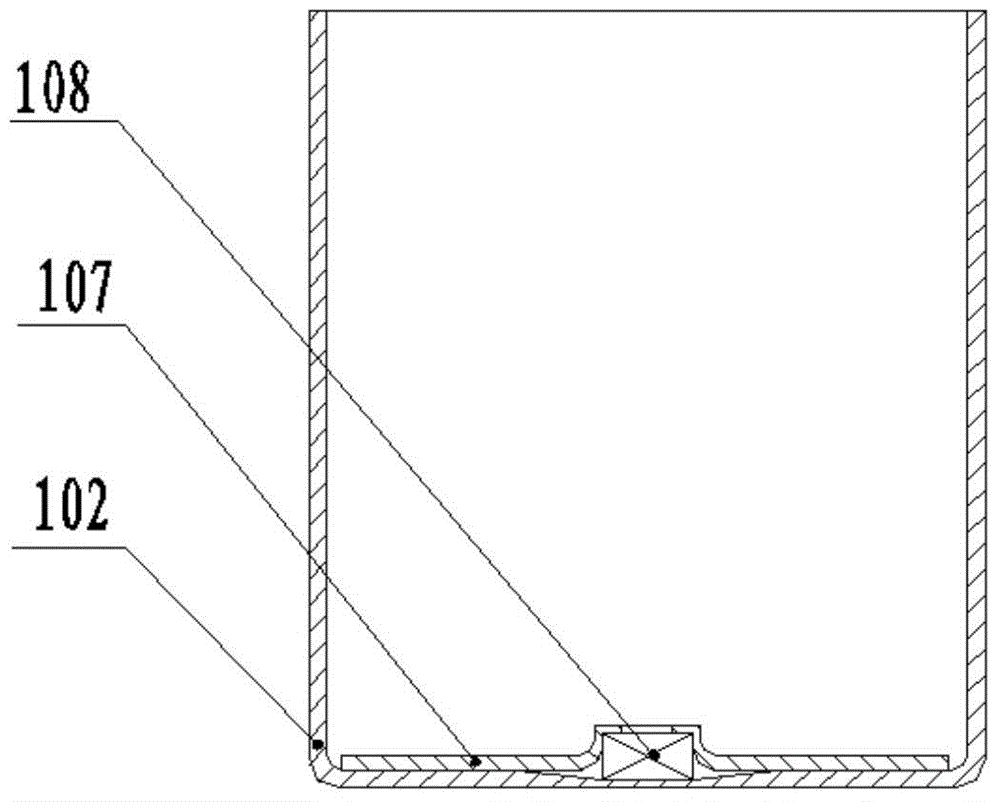

[0027] When the thermal battery 1 is made, the shell adopts the shell 102 and the flash cap seat 107 punched and formed respectively, and at the bottom of the shell 102, the shell 102 and the flash cap seat 107 are welded together by energy storage welding, and the flash cap After the seat 107 and the housing 102 are welded, the impact flash cap 108 is packed into the inner cavity of the flash cap seat 107, the cap of the flash cap seat 107 is closed with an oil press, the impact cap 108 is fixed, and then the thermal battery is loaded, wherein the thermal battery is conventionally The process can be assembled. Such a design makes the height of the overall structure of the strike cap 108 and the thermal battery low. The structure of the therma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com