Exhaust gas decomposer of hydrogen peroxide plasma sterilizer

A plasma and hydrogen peroxide technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of polluting the environment, rising, and threatening the health of equipment operators, and achieve the effect of decomposition and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

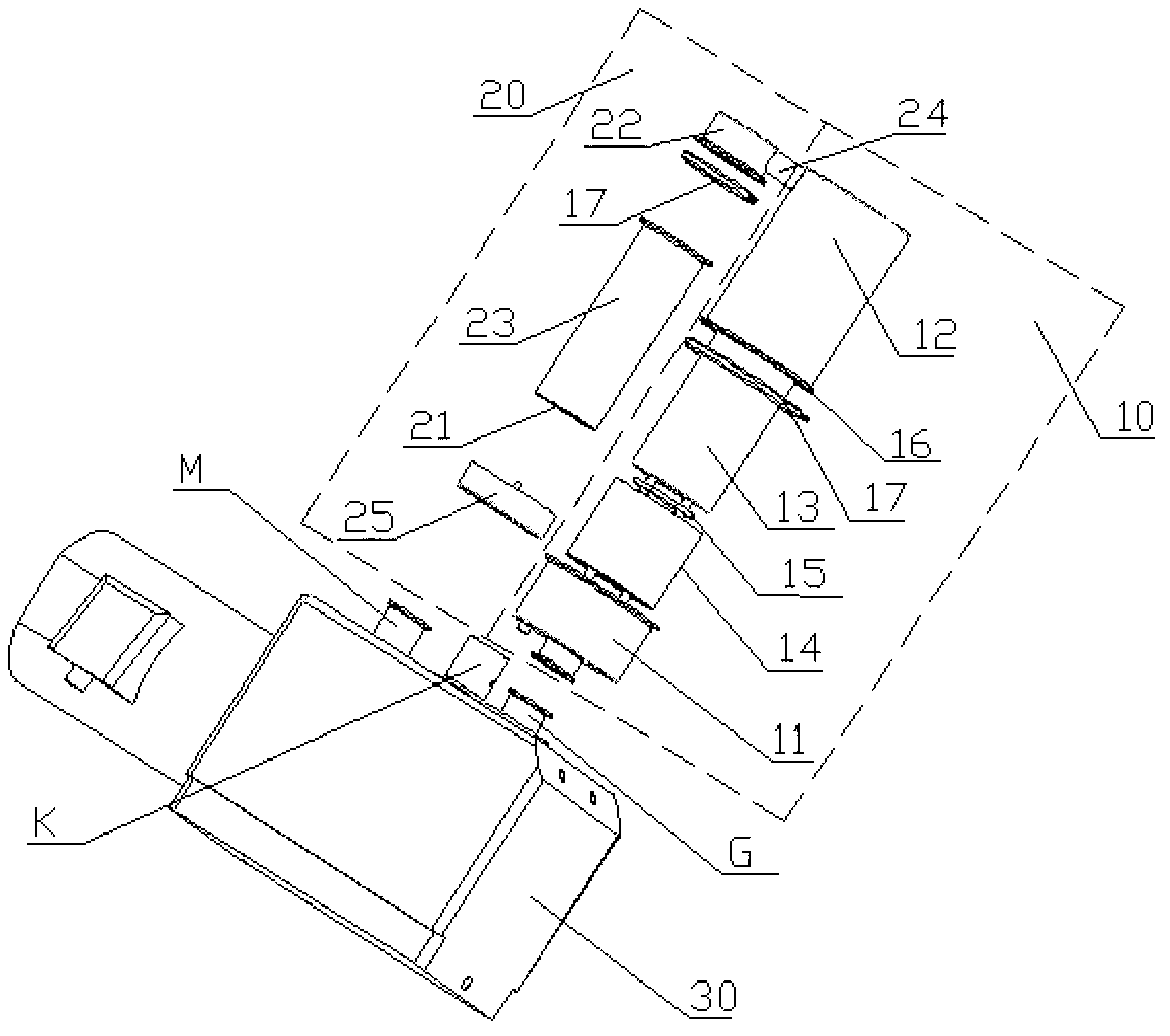

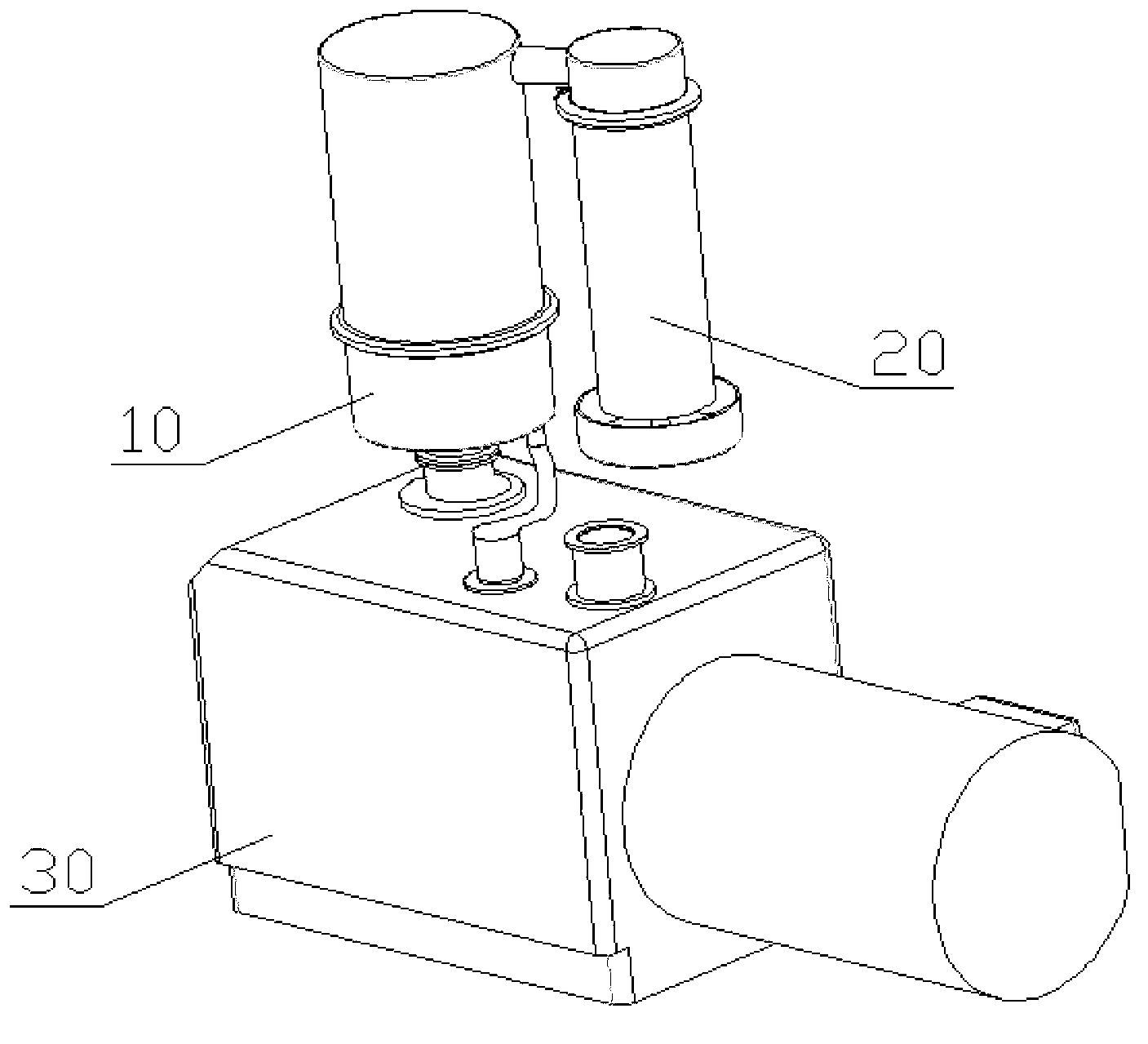

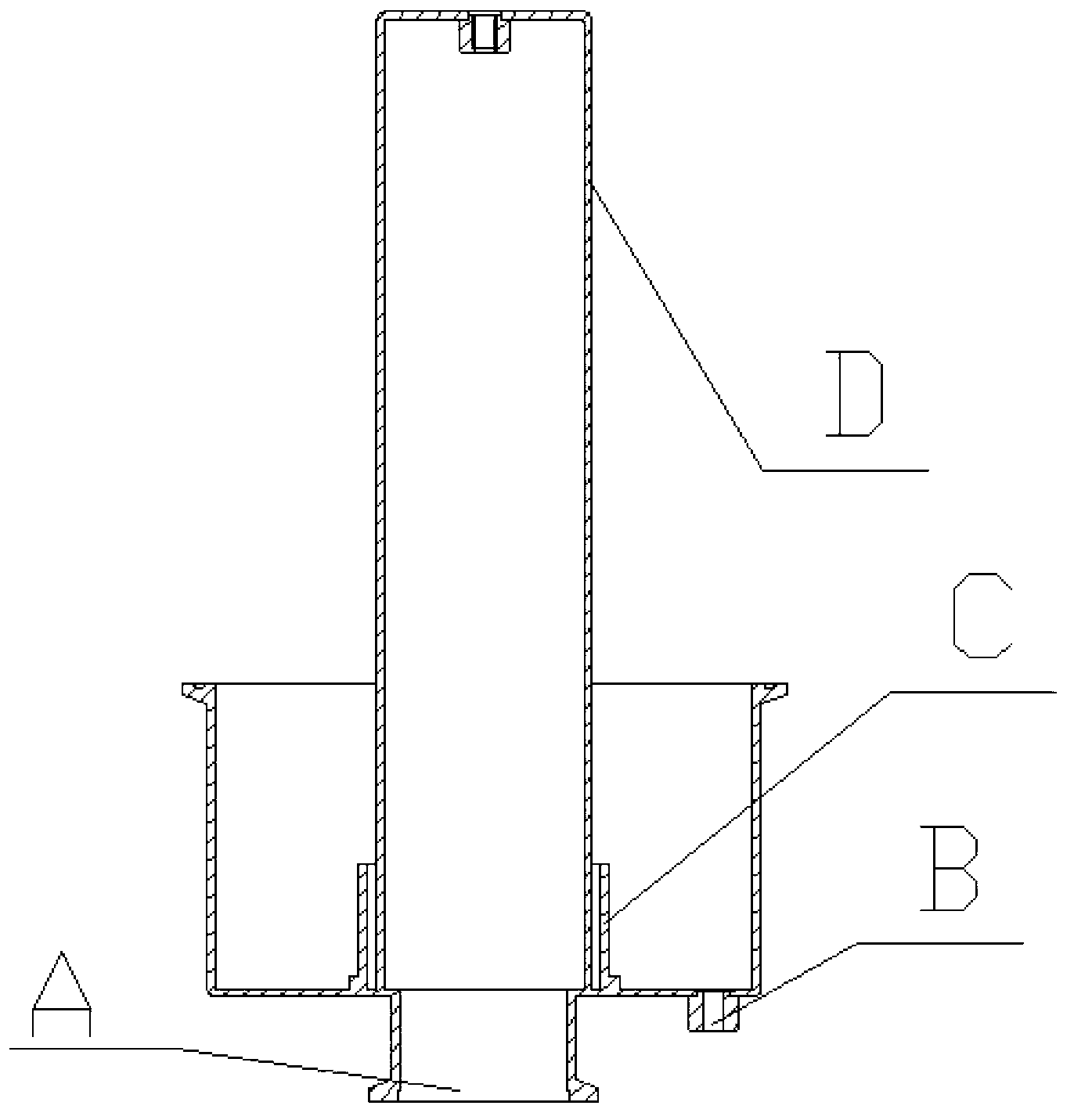

[0029] like Figure 1 to Figure 5 As shown, the first specific embodiment of the present invention is: a waste gas decomposition device of a hydrogen peroxide plasma sterilizer, which is vertically installed on the vacuum pump of the hydrogen peroxide low-temperature plasma sterilizer, including lubricating oil recovery System 10 and exhaust gas purification system 20, the lubricating oil recovery system 10 is composed of lower casing 11, upper casing 12, filter element 13 and condensation cover 14, the lower casing 11, upper casing 12 and condensation cover 14 are all made of stainless steel Production, an air inlet A and a return port B are provided at the end of the lower housing 11, the air inlet A is connected to the exhaust hole G of the vacuum pump 30, and the return port B is connected to the return hole K of the vacuum pump 30. Filter element 13 is columnar, adopts hollow structure, and its one end is open, and the filter layer of filter element 13 uses macromolecular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com