Serial system light source control method for improving grade of methane by microalgae

A tandem biogas technology, applied in the field of environmental engineering, can solve problems such as high process complexity, high cost of adsorbent, and insufficient stability of the effect, and achieve the effects of improving economic efficiency, saving costs, and avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

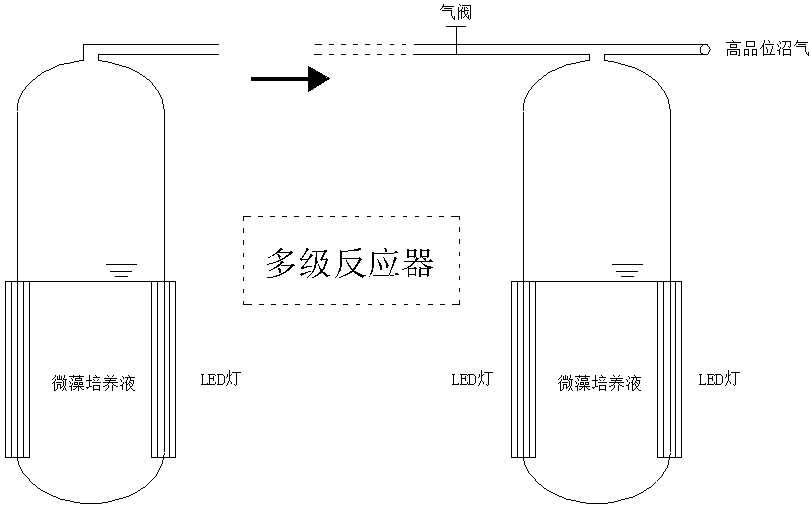

Method used

Image

Examples

Embodiment 1

[0023] A tandem system light source control and energy saving method using microalgae to improve biogas grade: the tandem system has a total of 9 stages, the size of each stage is 3 m×3 m×3 m, and the biogas slurry is 1.0 m 3 As a nutrient substrate for microalgae cultivation, the volume of biogas is 8.0 m 3 ; inoculated with diatoms Nitzki Nitzschia palea The initial density is 400 mg L -1 , the photoperiod is 12 h / 12 h, the control temperature of the system reactor is 30±0.5 °C, the working time of each reactor is 72 h, and the fixed light intensity is 300 μmol m -2 the s -1 ; Optimize the light quality, and compare the biogas grade improvement effects of red light, blue light, yellow light, green light and white light of different light quality LED lights.

[0024] The raw biogas grade is CH 4 The content is 57.21±8.96%. After the quality of red light, blue light, yellow light, green light and white light of the series system LED light quality is improved, they resp...

Embodiment 2

[0026] A tandem system light source control and energy saving method using microalgae to improve biogas grade: the tandem system has a total of 10 stages, and the size of each stage is 2 m×2 m×4 m, and the biogas slurry is 2.0 m 3 As a nutrient substrate for microalgae cultivation, the volume of biogas is 14.0 m 3 ; Inoculated with Chlorella Chlorella sp. The initial density is 350 mg L -1 , the photoperiod is 12 h / 12 h, the control temperature of the system reactor is 25±0.5 °C, the working time of each reactor is 72 h, and the red light quality of LED is fixed; the light intensity is optimized, and the fixed light intensity experiment group is compared with 50 , 100, 200, 300 and 400 μmol m -2 the s -1 The effect of biogas grade improvement.

[0027] The raw biogas grade is CH 4 The content is 60.83±7.36%, after the series system LED fixed light intensity 50, 100, 200, 300 and 400 μmol m -2 the s -1 After the grade upgrade, respectively reach CH 4 The contents a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com