Double-flow injection-type floatation method and double-flow injection-type floatation device

An injection type, flotation cell technology, used in flotation, solid separation and other directions, can solve the problem of the uneven distribution of bubbles and bubbles, and achieve the effect of good aeration performance, uniform bubble distribution and good flotation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Compared with the cumulative index of Chehe concentrator industrial test and the cumulative index of the flotation machine currently used in this plant: in the case of equivalent raw ore grade, the Pb grade in the concentrate has increased by 0.10%, and the Zn grade has increased by 1.37% %, the Pb recovery rate increased by 4.93%, and the Zn recovery rate increased by 4.11%. The flotation performance of the flotation machine is better than that of the flotation machine currently used in the plant, which proves that the flotation machine has a good flotation effect and meets the design requirements.

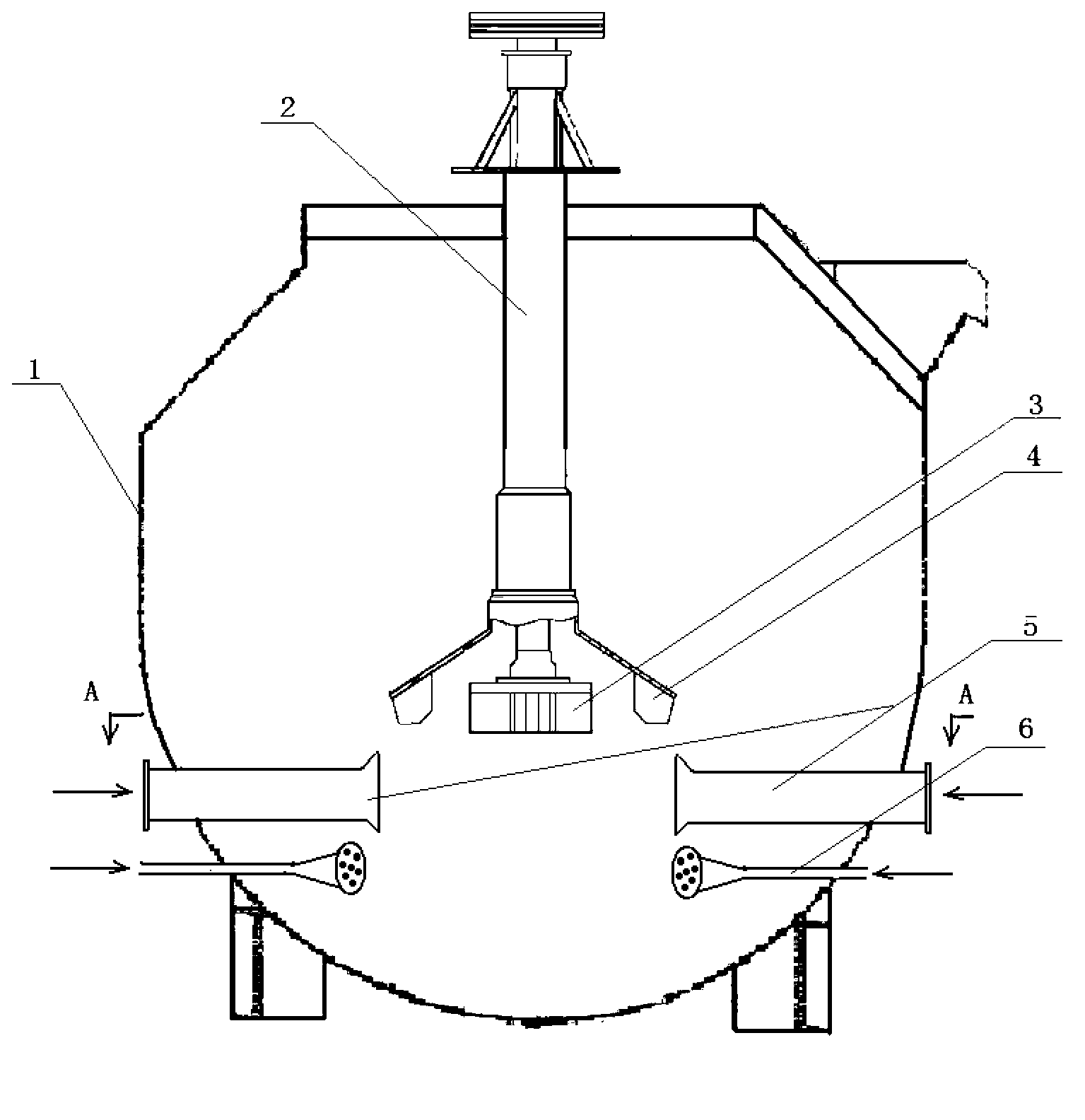

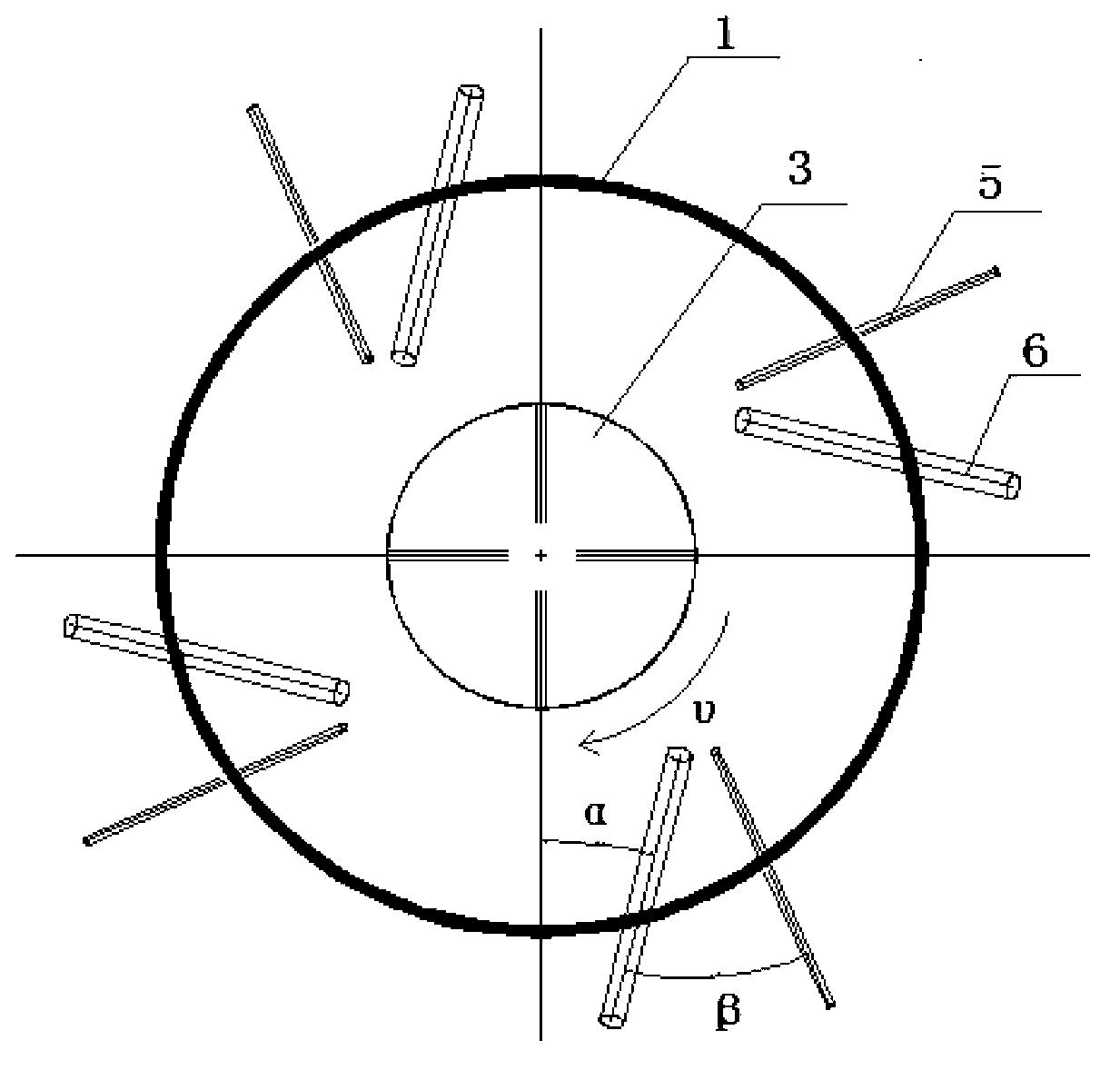

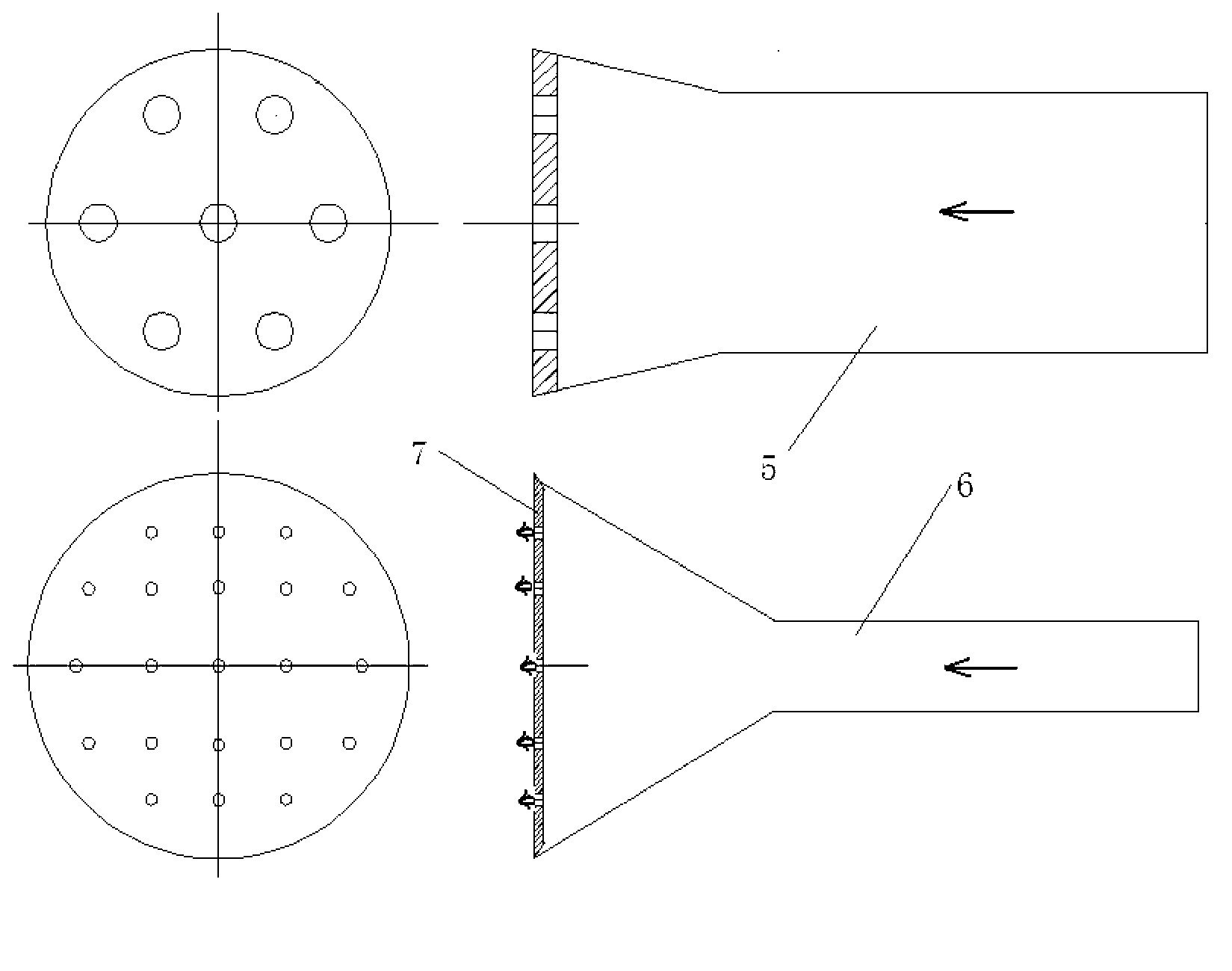

[0021] The double-flow injection flotation method and its device of the present invention have the following advantages: both the pulp and the compressed air are sprayed into the flotation cell (1) in the form of multiple streams of fluids, blended and collided and mixed, and then merged into the flotation cell (1). A swirling flow is formed in the flotation cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com