Method for synthesizing NiO nanocube particles through milisecond pulsed laser

A nano-cube and pulsed laser technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of small output, difficult control of reaction conditions, low product purity, etc., and achieve particle size distribution Uniform, safe and controllable reaction process, simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

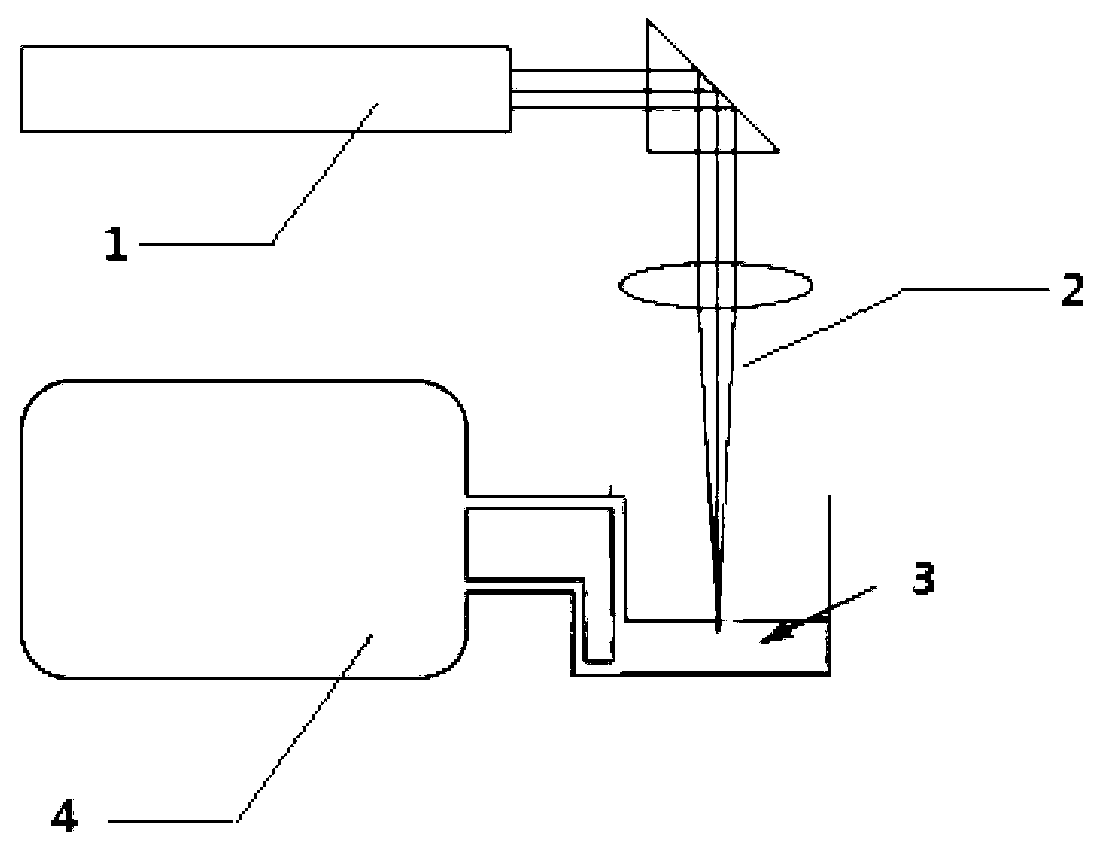

Method used

Image

Examples

Embodiment 1

[0026] The output wavelength of Nd-YAG solid-state laser is 1064nm, and the power density is 10 6 W / cm2, pulse width 0.6ms, pulsed laser beam with frequency 10Hz, the laser beam is focused at about 1mm below the surface of the liquid medium, and the spot size is about 0.2mm.

[0027] Mix metal nickel powder with a particle size of 50 μm and deionized water, and use a submersible pump to continuously circulate and disperse it during the reaction.

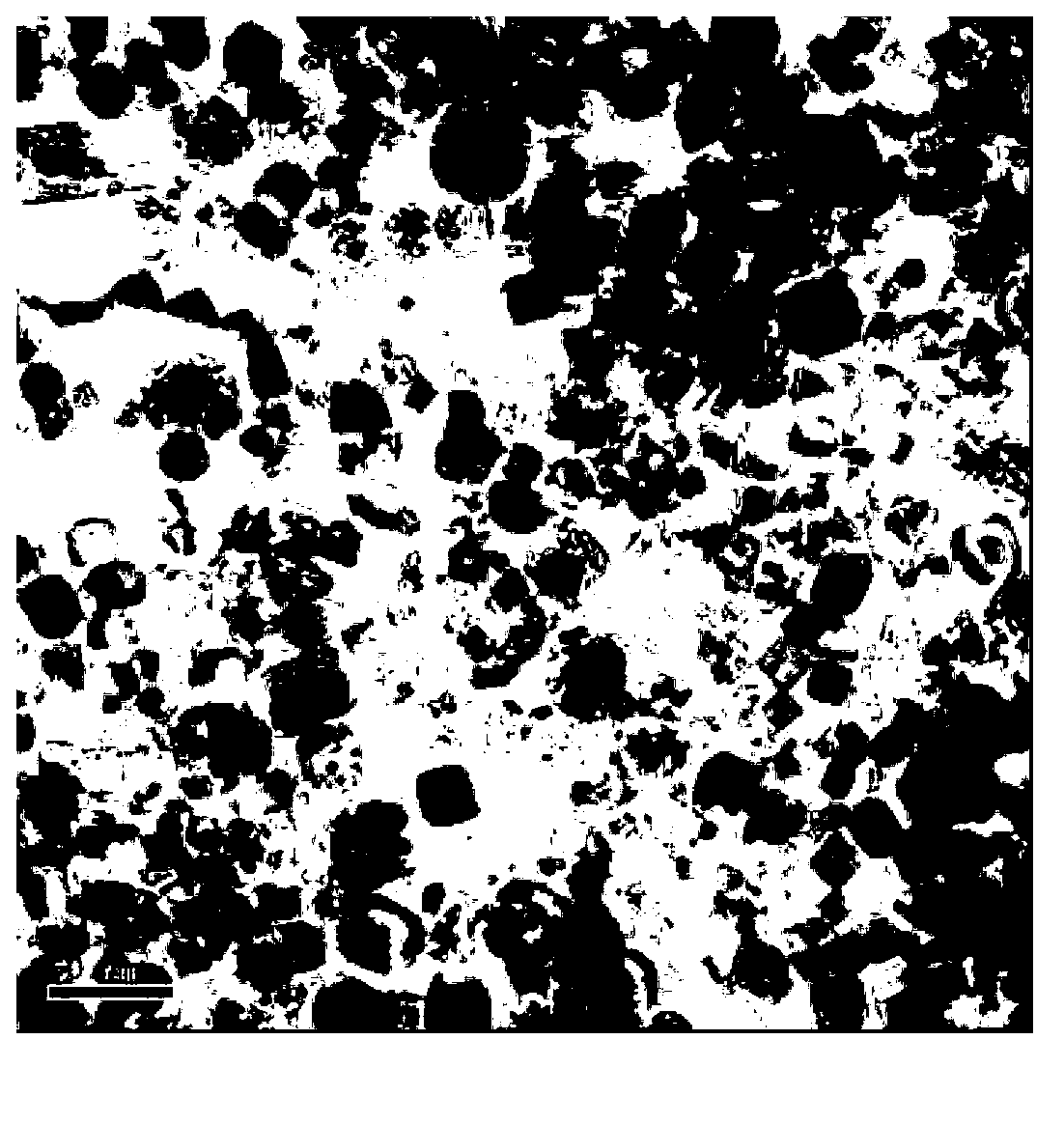

[0028] The metal nickel powder in the water is bombarded with a millisecond pulse laser, and the laser focus is converged at an appropriate distance below the water surface, creating a high-temperature and high-pressure micro-zone at the laser focus, which promotes the gasification of the metal nickel particles in the micro-zone and then forms in the process of condensation. NiO nanocube particles. The laser power density in the active area is 10 6 W / cm 2 , The time of laser action is 10h.

[0029] Among them: metal nickel powder...

Embodiment 2

[0032] The output wavelength of Nd-YAG solid-state laser is 1064nm, and the power density is 10 7 W / cm2, pulse width 1.0ms, pulsed laser beam with a frequency of 20Hz, the laser beam is focused at about 2mm below the surface of the liquid medium, and the spot size is about 0.3mm.

[0033] Mix metal nickel powder with a particle size of 45 μm and deionized water, and use a submersible pump to continuously circulate and disperse it during the reaction.

[0034] The metal nickel powder in the water is bombarded with a millisecond pulse laser, and the laser focus is converged at an appropriate distance below the water surface, creating a high-temperature and high-pressure micro-zone at the laser focus, which promotes the gasification of the metal nickel particles in the micro-zone and then forms in the process of condensation. NiO nanocube particles. The laser power density in the active area is 10 7 W / cm 2 , The time of laser action is 5h.

[0035] Among them: metal nickel po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com