Method and device for wastewater treatment and salt extraction during hydrazine hydrate production by ketazine process

A technology of ketazine method and wastewater treatment, which is applied in the directions of water/sewage multi-stage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc. To deal with problems such as difficult to control and so on, to achieve the effect of saving production cost, reducing pollution and making full use of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

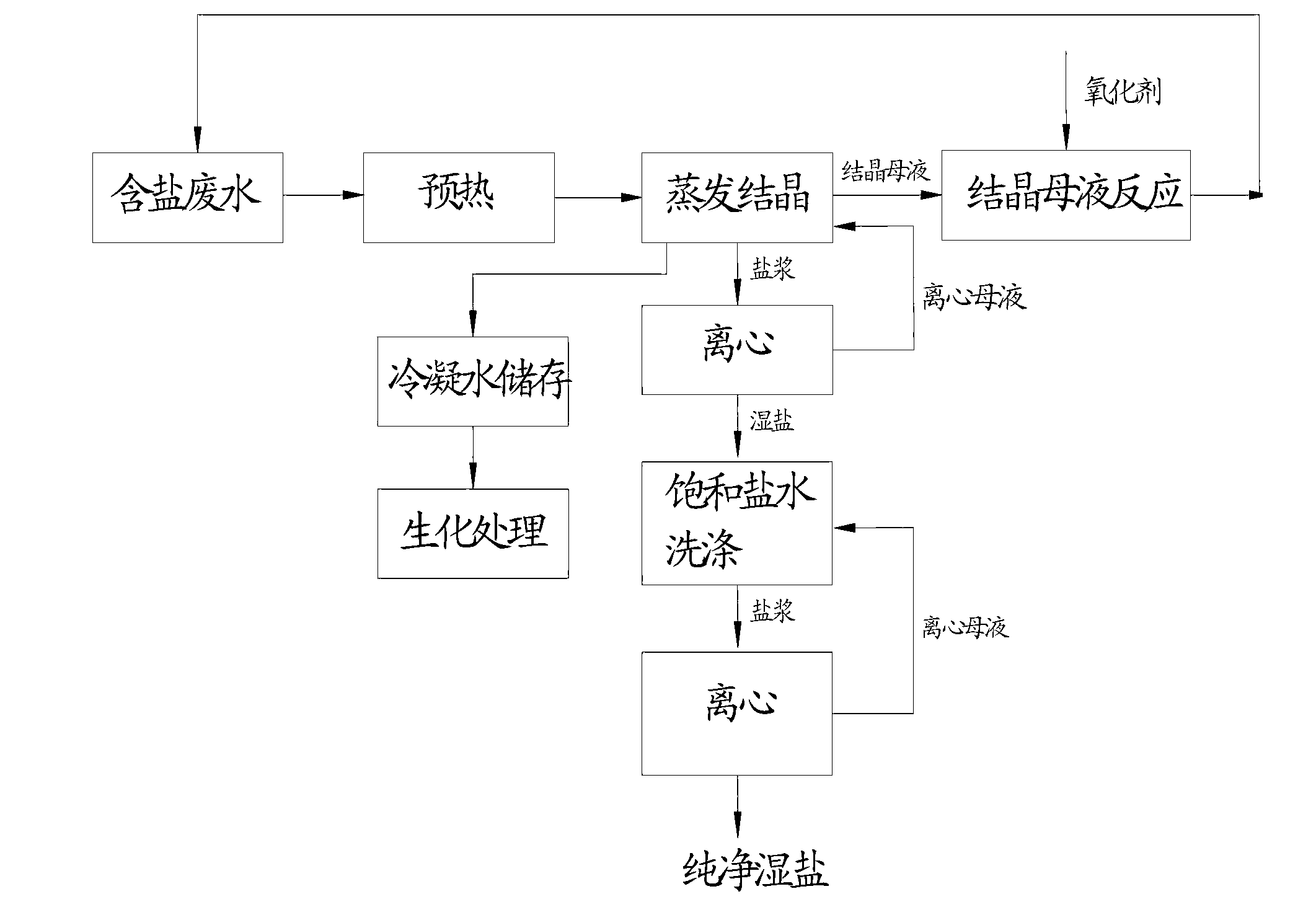

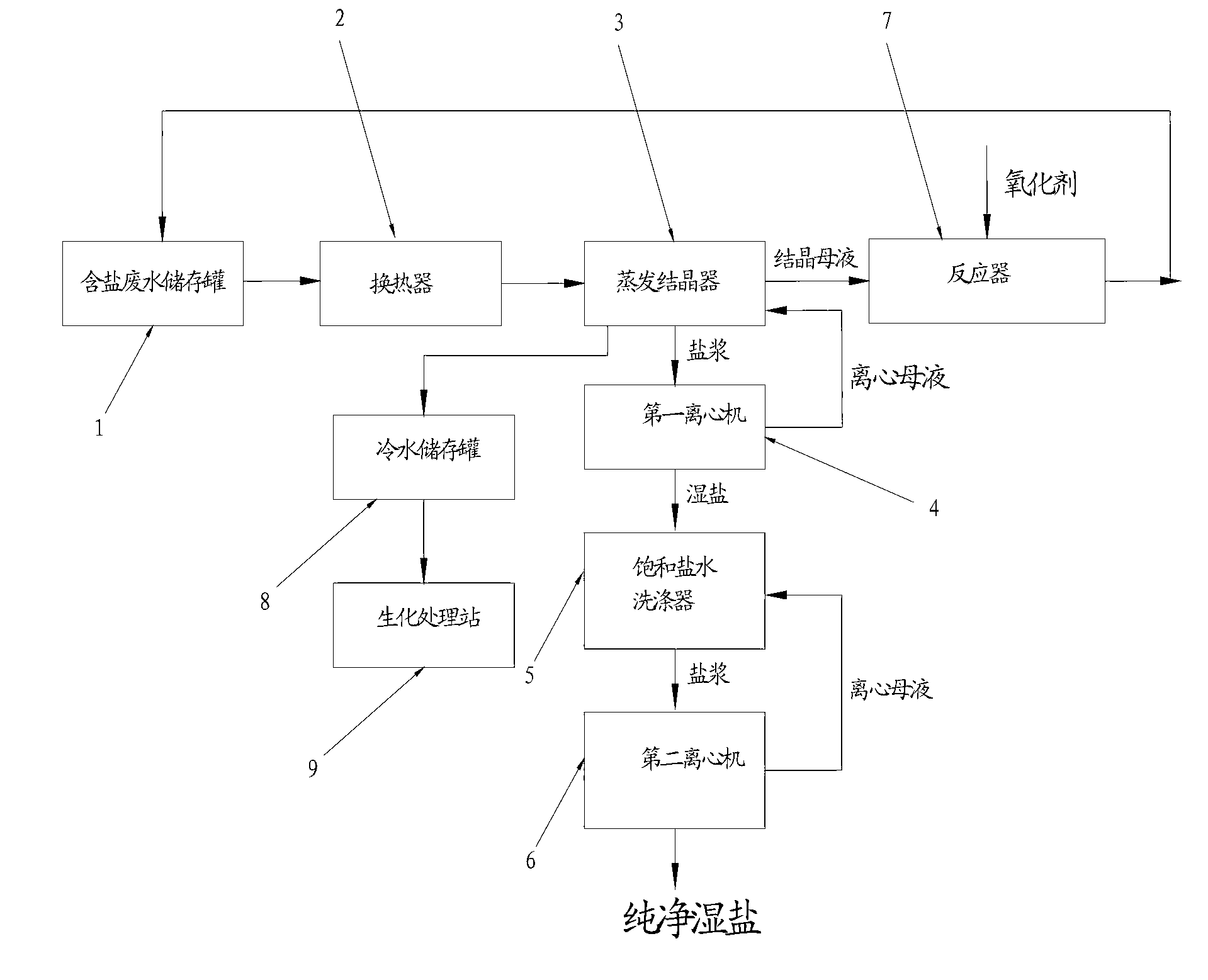

[0037] Please refer to figure 1 , the ketazine method of the present invention produces the wastewater treatment of hydrazine hydrate and the method for extracting salt, it is characterized in that comprising the following steps in sequence:

[0038] 1) Recycling and storage of saline wastewater;

[0039] 2) Preheat the waste water to 80-100°C;

[0040] 3) Waste water is evaporated and crystallized in the mechanical vapor recompression cycle evaporation system. The temperature of evaporation and crystallization is 50-120°C to obtain salt slurry and crystallization mother liquor. The water vapor generated by evaporation is condensed into condensed water and then enters the cold water storage tank. The condensed water After heat exchange and cooling, it enters the biochemical treatment station, and is reused or discharged after being treated by biochemical methods. After the crystallization mother liquor reacts with the oxidant, it is recovered and stored as saline wastewater; ...

Embodiment 2

[0047] The difference between this embodiment and embodiment 1 lies in: Step 3) The waste water is evaporated and crystallized by using a multi-effect concentration and evaporation system, and the temperature of the evaporation and crystallization is 50-120°C. After the waste water is preheated, it is evaporated in effect I, and then advectively enters effect II, effect III, effect IV, effect V, and effect VI to evaporate, choose to crystallize and discharge salt in effect V and effect VI, and extract crystallization mother liquor in effect VI for recycling treatment. The raw steam first enters the I effect as the heat source, the secondary steam of the I effect acts as the heat source of the II effect, and in turn, the secondary steam of the former effect acts as the heat source of the after effect. The source of the condensed water of effect I is raw steam, so it can be reused directly after heat exchange. The condensed water of other effects contains various organic impuriti...

Embodiment 3

[0049] The difference between this example and Example 2 is that the pH value of the saline wastewater is adjusted to 7 before preheating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com