LDPE (low density polyethylene) grafting maleic anhydride waste water resourcelization recycling method

A technology of low-density polyethylene grafted with maleic anhydride, which is applied in the field of waste water recycling and can solve the problems of low percentage and waste of effective resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

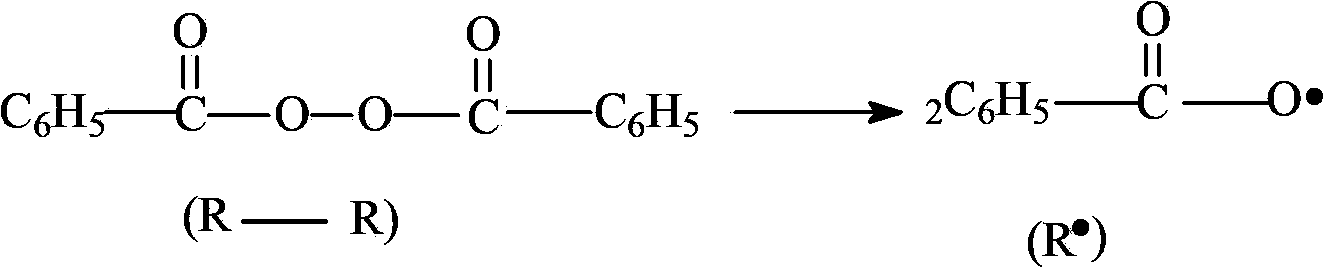

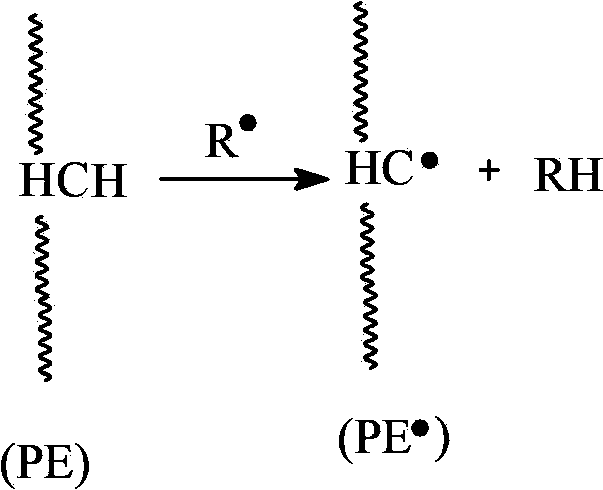

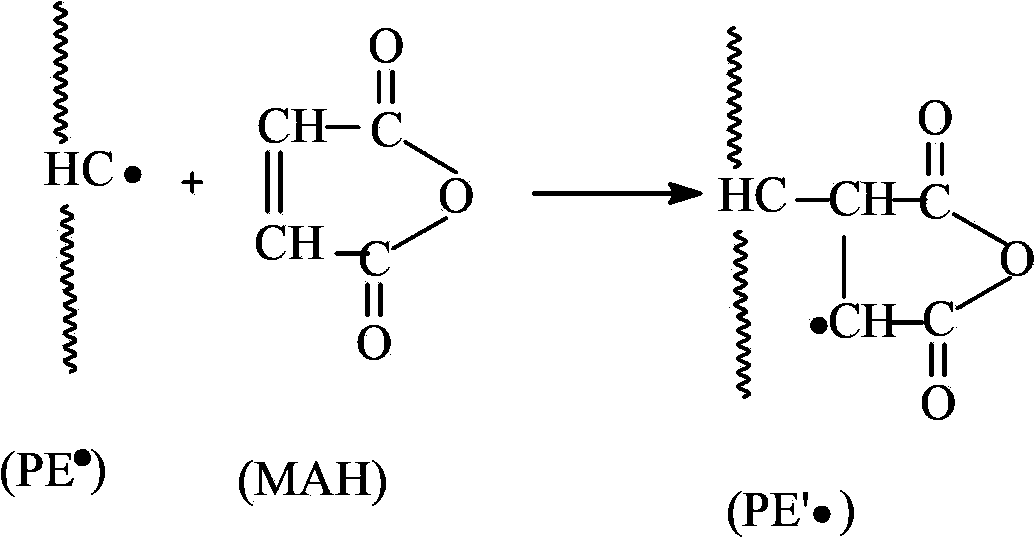

Method used

Image

Examples

Embodiment

[0029] The low-density polyethylene grafted maleic anhydride waste water recycling method of the present embodiment comprises the following steps:

[0030] The first step is to add 60-100ml of solvent xylene (that is, the volume of xylene accounts for 24-50% of the volume of wastewater) and 16-20g of LDPE powder (that is, LDPE powder The ratio of weight to waste water volume is 64-100mg / ml), under the condition of reflux condensation, heat to 80-100°C and stir evenly to obtain premixed liquid. Note: LDPE is low density polyethylene.

[0031] Specifically, low-density polyethylene grafted maleic anhydride waste water can be mixed with tap water in a weight ratio of 1:1-1:3, and then the solvent xylene and LDPE powder can be added. The container used in this step is a flask with a reflux condenser and a thermometer.

[0032] Step 2: Add MAH, surfactant and dispersant to the premixed liquid, stir evenly at a temperature of 80-100° C. to obtain a reaction liquid; transfer the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com