Preparation method and application of modified humic acid quaternary ammonium salt

A humate, quaternary ammonium salt technology, applied in plant growth regulators, chemicals for biological control, pest control and other directions, to achieve high application value, growth promotion, and good activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

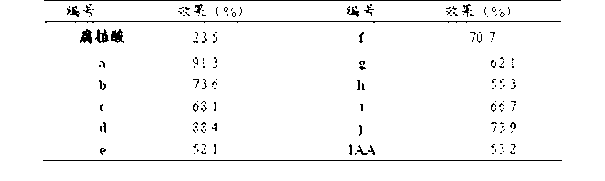

Examples

Embodiment 1

[0012] Embodiment one: Modified humic acid quaternary ammonium salt a preparation of

[0013] (1) Break the weathered coal with a pulverizer, pass through a 70-mesh sieve, take 10 g of weathered coal containing 35% humic acid, add 50 mL of hydrochloric acid with a mass concentration of 2% at 40 °C, and mix it under stirring. After reacting for 30 min, 15% sodium hydroxide was added to react until the pH of the system was 10.0. Continue to stir for 15 min, stop the reaction, centrifuge at a high speed of 4500 r / min, take the upper liquid, and dry and dehydrate with a rotary evaporator to obtain a black solid that is sodium humate.

[0014] (2) Take 3.0 g of sodium humate prepared in step (1) and place it in a 100 mL three-necked flask equipped with a condensing device, stir and dissolve it with 45 mL of water at room temperature, and take 1.3 g of 3-chloro-2-hydroxypropyl tris Dissolve methyl ammonium chloride with a small amount of water and add dropwise through a constant ...

Embodiment 2

[0015] Embodiment two: modified humic acid quaternary ammonium salt b preparation of

[0016] It was synthesized according to the conditions and method of Example 1, except that 1.4 g of 3-chloro-2-hydroxypropyltrimethylammonium nitrate was added in step (2).

Embodiment 3

[0017] Embodiment three: modified humic acid quaternary ammonium salt c preparation of

[0018] It was synthesized according to the conditions and method of Example 1, except that 1.2 g of 3-chloro-2-hydroxypropyltrimethylammonium hydrogensulfate was added in step (2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com