Novel special inorganic hole-sealing agent for thermal-spraying coating as well as preparation method and application for same

A sealing agent and thermal spraying technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of high sealing cost, complicated sealing process, and poor sealing resistance to high temperature, and achieve good sealing effect and corrosion resistance. Excellent, water-blocking performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

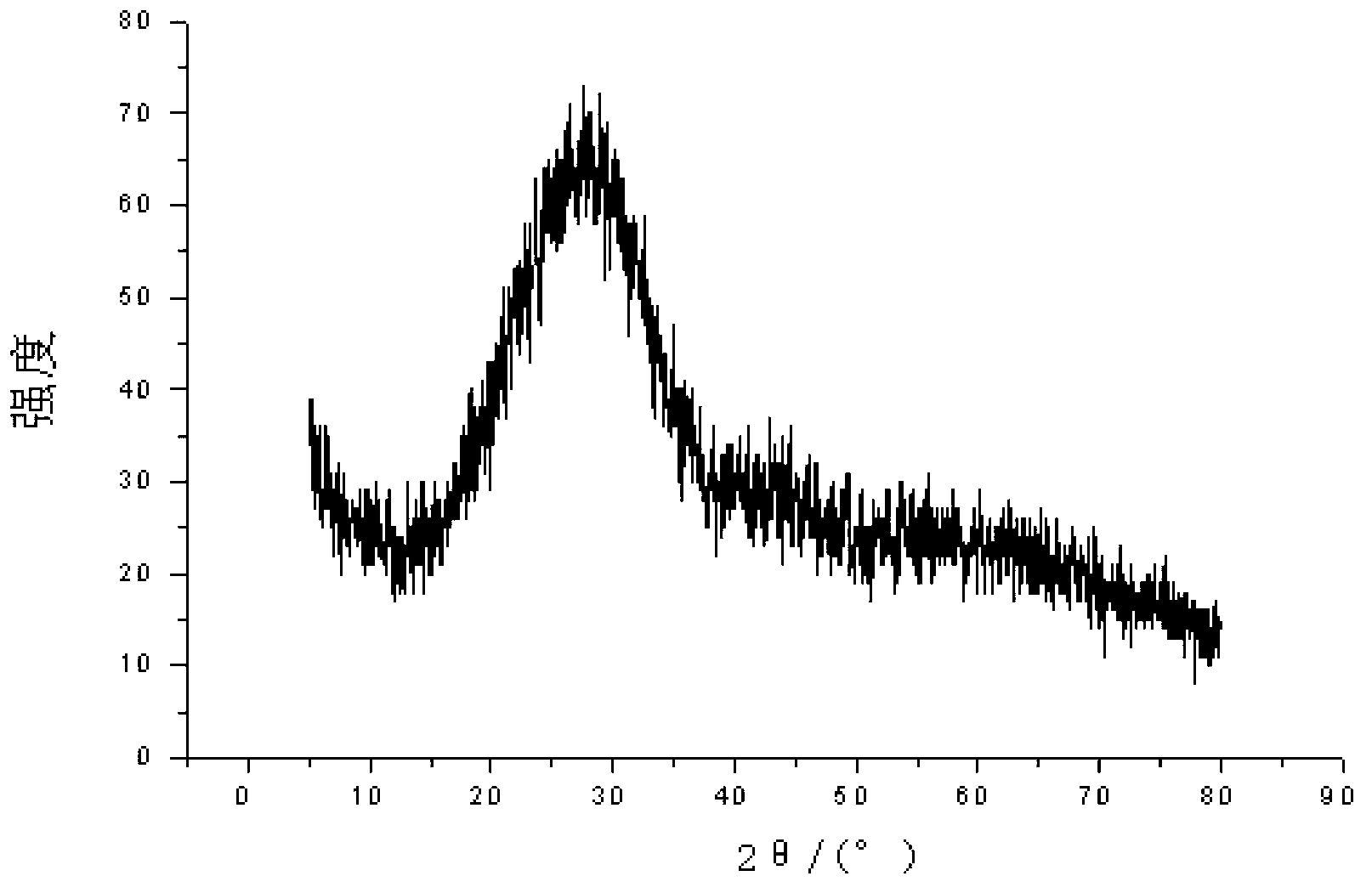

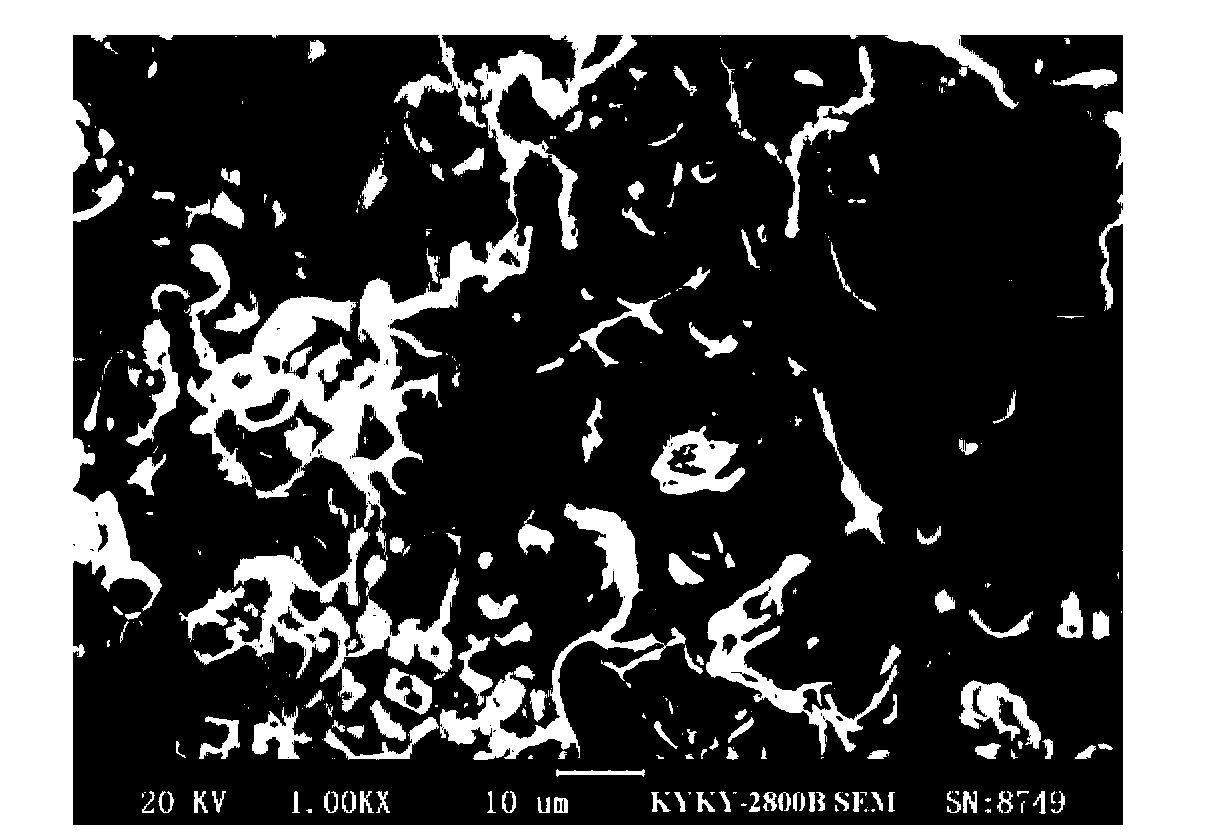

[0043] The preparation method and application of the sealing agent of the present invention will be described in detail below according to the accompanying drawings and specific examples

[0044] The first step: preparation of inorganic sealing agent

[0045] First, mix the mixture evenly according to the mass fraction (as shown in Table 2).

[0046] Table 2 Chemical composition of inorganic sealing materials

[0047] composition

SiO 2

al 2 o 3

B 2 o 3

Na 2 CO 3

CaF 2

ZnO

Ni 2 o 3

Na 5 P 3 o 10

TiO 2

co 2 o 3

content

36.12

5.15

17.16

18.38

3.52

6.32

2.06

6.24

4.05

1

[0048] Step 2: put the mixture into the crucible, then put it into a common electric furnace and heat it to 500°C for 30 minutes to remove the moisture in the raw material, and at the same time Na 2 CO 3 decomposes to release CO 2 gas.

[0049] Step 3: Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com