Epoxy non-isocyanate polyurethane heavy anti-corrosion coating

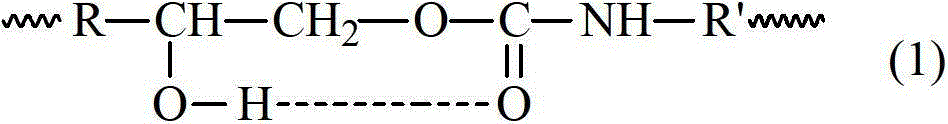

An epoxy non-isocyanate, polyurethane technology, used in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve problems such as isocyanate group toxicity, achieve good mechanical properties, reduce hydrophilicity and hydrolyzability, and optimize The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 340g of bisphenol F epoxy resin NPEF-170 and 3.4g of tetrabutylammonium bromide into a 500ml autoclave, and feed CO 2 When the pressure in the kettle reaches 1.5 MPa, heat to 115° C. and react for 6 hours to obtain a mixture of ring-terminated carbonate compound and epoxy compound, wherein the conversion rate of epoxy group to cyclocarbonate group is 41%.

[0031] Take 37.6g of the product from the previous step and 19.8g of amino-terminated polyether T-403 into a high-speed mixer, stir evenly, and spray evenly on the surface of the test piece to prepare a high-hardness epoxy non-isocyanate polyurethane heavy-duty anti-corrosion coating.

Embodiment 2

[0033] Add 340g of bisphenol F epoxy resin NPEF-170 and 3.4g of tetraethylammonium bromide into a 500ml autoclave, and feed CO 2 When the pressure in the kettle reaches 1.5 MPa, heat to 120° C. and react for 9 hours to obtain a mixture of ring-terminated carbonate compound and epoxy compound, wherein the conversion rate of epoxy group to cyclocarbonate group is 55%.

[0034] Take 38.8g of the product from the previous step and 18.6g of amino-terminated polyether D-230 into a high-speed mixer, stir evenly, and spray evenly on the surface of the test piece to prepare an epoxy non-isocyanate polyurethane heavy-duty anti-corrosion coating with moderate hardness.

Embodiment 3

[0036] Add 340g of bisphenol F epoxy resin NPEF-170 and 3.4g of cetyltrimethylammonium chloride into a 500ml autoclave, and feed CO 2 When the pressure in the kettle reaches 2.1MPa, heat to 130°C and react for 10 hours to obtain a mixture of ring-terminated carbonate group compound and epoxy compound, wherein the conversion rate of epoxy group to cyclocarbonate group is 70%.

[0037] Take 40g of the product from the previous step, 3g of glycerol triglycidyl ether, and 36g of amino-terminated polyether D400 and put them into a high-speed mixer. After stirring evenly, spray evenly on the surface of the test piece to prepare a flexible epoxy non-isocyanate polyurethane heavy-duty anti-corrosion coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com