Ion exchange film operated under ultrahigh current density condition and preparation method of ion exchange film

An ion-exchange membrane and high-elastic membrane technology, applied in the field of ion-exchange membranes, can solve the problems of reduced hydroxide barrier performance, mismatch of carboxylic acid resins, shortened life, etc. long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

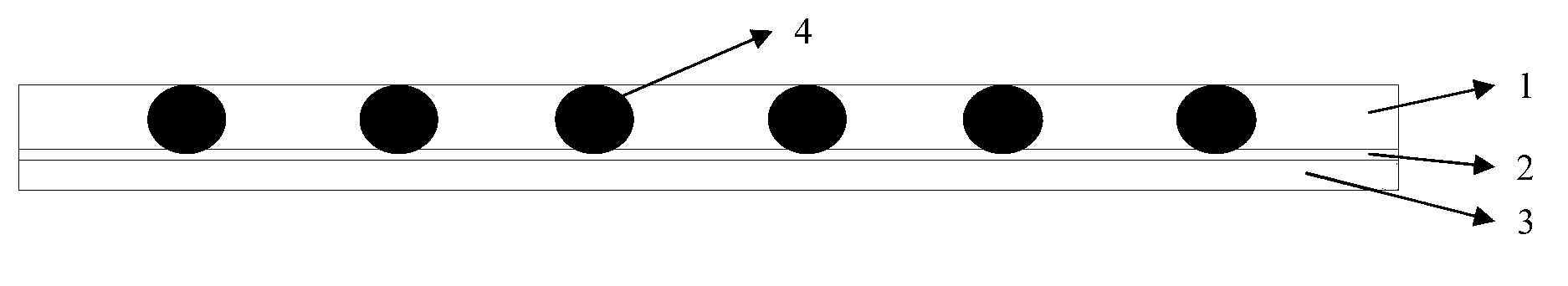

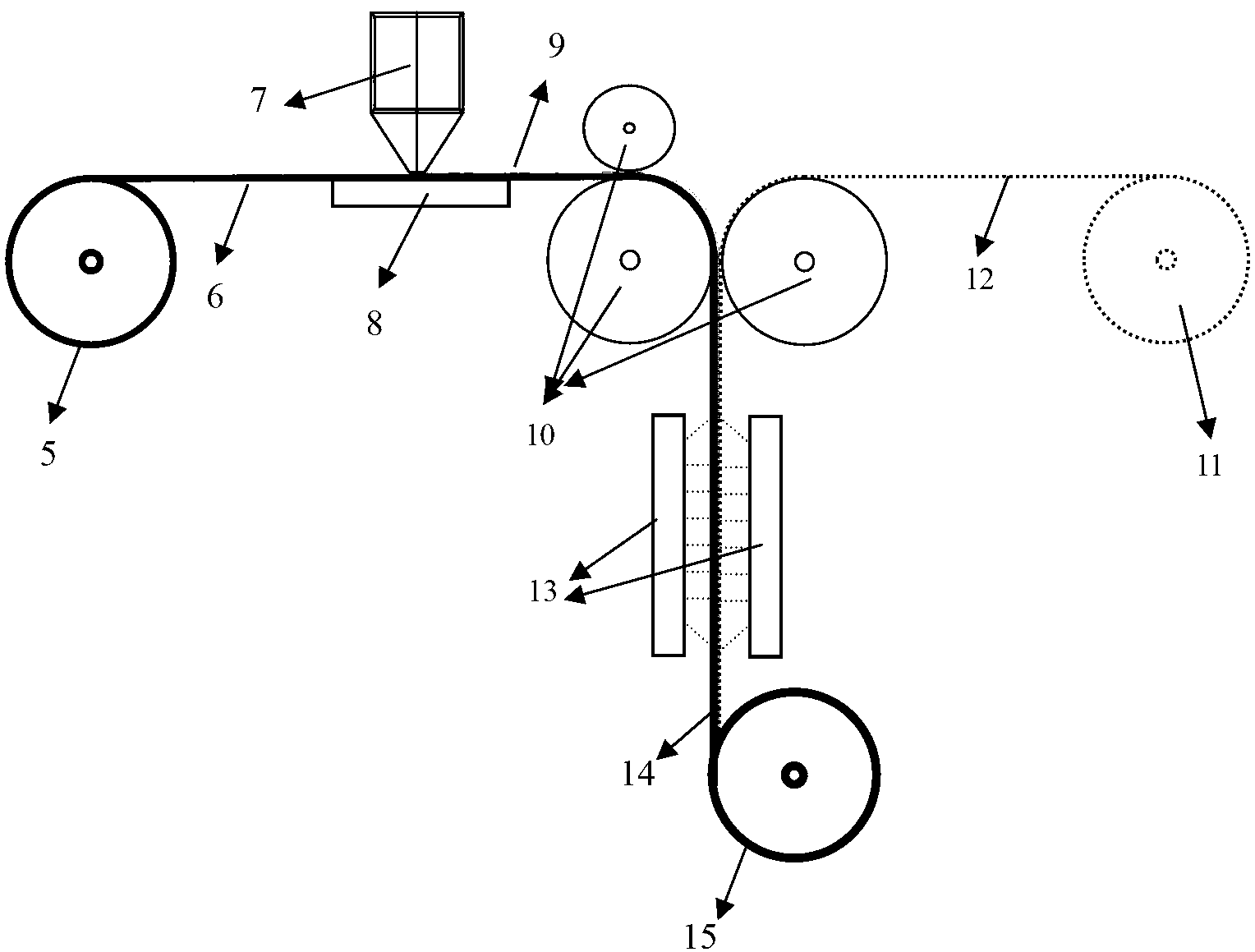

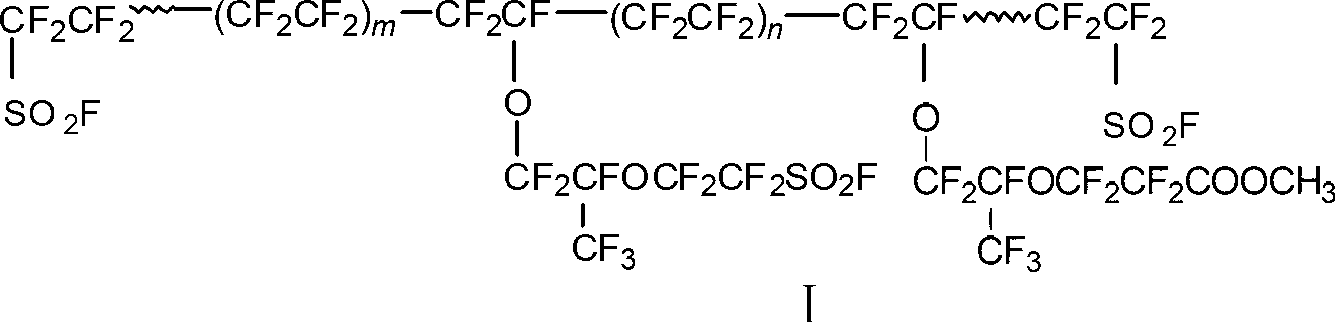

[0041] Perfluorosulfonic acid resin with IEC=1.4mmol / g (M in formula II is -SO 2 F, x=2.9, n=1, m=3) melted and casted through an extruder to form a single film of perfluorosulfonic acid resin with a thickness of 100 microns; the perfluorocarboxylic acid resin (formula II M is -COOCH 3 , x=6.3, n=1, m=3) to form a single film of perfluorocarboxylic acid resin with a thickness of 15 microns by melt casting through an extruder; Melt adhesive (m=8, n=10 in Formula I) is melted at 155°C through an extruder and then coated on one surface of a perfluorosulfonic acid resin single film through a casting head to form a perfluoroadhesive The high-elastic film layer with a thickness of 5 microns; at the same time, a single film of perfluorocarboxylic acid resin is introduced and pressed together to form a three-layer composite film with a three-layer structure; finally, the PTFE fiber mesh and the perfluorosulfonic acid of the composite film The resin layers are thermocompressed to for...

Embodiment 2

[0044] Perfluorosulfonic acid resin with IEC=1.15mmol / g (M in formula II is -SO 2 F, x=5.1, n=0, m=5) melted and casted through an extruder to form a single film of perfluorosulfonic acid resin with a thickness of 120 microns; the perfluorocarboxylic acid resin (formula II M is -COOCH 3 , x=8.7, n=1, m=3) to form a single film of perfluorocarboxylic acid resin with a thickness of 8 microns by melt casting through an extruder; Melt adhesive (m=8, n=8 in Formula I) is melted at 175°C through an extruder and then coated on one surface of a perfluorosulfonic acid resin single film through a casting head to form a perfluoroadhesive The high-elastic film layer with a thickness of 8 microns; at the same time, a single film of perfluorocarboxylic acid resin is introduced and pressed together to form a three-layer composite film with a three-layer structure; finally, the PTFE porous film and the perfluorosulfonic acid of the composite film The resin layers are thermocompressed to for...

Embodiment 3

[0047] Perfluorosulfonic acid resin with IEC=1.55mmol / g (M in formula II is -SO 2 F, x=2.1, n=0, m=3) melted and casted through an extruder to form a single film of perfluorosulfonic acid resin with a thickness of 70 microns; the perfluorocarboxylic acid resin (formula II M is -COOCH 3 , x=6.7, n=0, m=3) to form a single film of perfluorocarboxylic acid resin with a thickness of 10 microns by melting and casting through an extruder; Melt adhesive (m=7, n=8 in Formula I) is melted at 145°C through an extruder and then coated on one surface of a perfluorosulfonic acid resin single film through a casting head to form a perfluoroadhesive The high-elastic film layer with a thickness of 4 microns; at the same time, a single film of perfluorocarboxylic acid resin is introduced and pressed together to form a three-layer composite film with a three-layer structure; finally, the PFA fiber mesh and the perfluorosulfonic acid of the composite film The resin layers are thermocompressed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Burst resistance | aaaaa | aaaaa |

| Burst resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com