A swirl pulverized coal burner

A pulverized coal burner and axial swirling technology, which is applied to burners, burners for burning pulverized fuel, combustion methods, etc., can solve the problem that the diameter and length of the recirculation zone of the nozzle cannot meet the requirements, the adjustment ability is reduced, and the swirling flow Intensity adjustment performance is poor and other problems, to achieve the effect of strengthening ignition stability and burnout performance, strong adaptability to changing coal types, and enhancement of adjustment ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

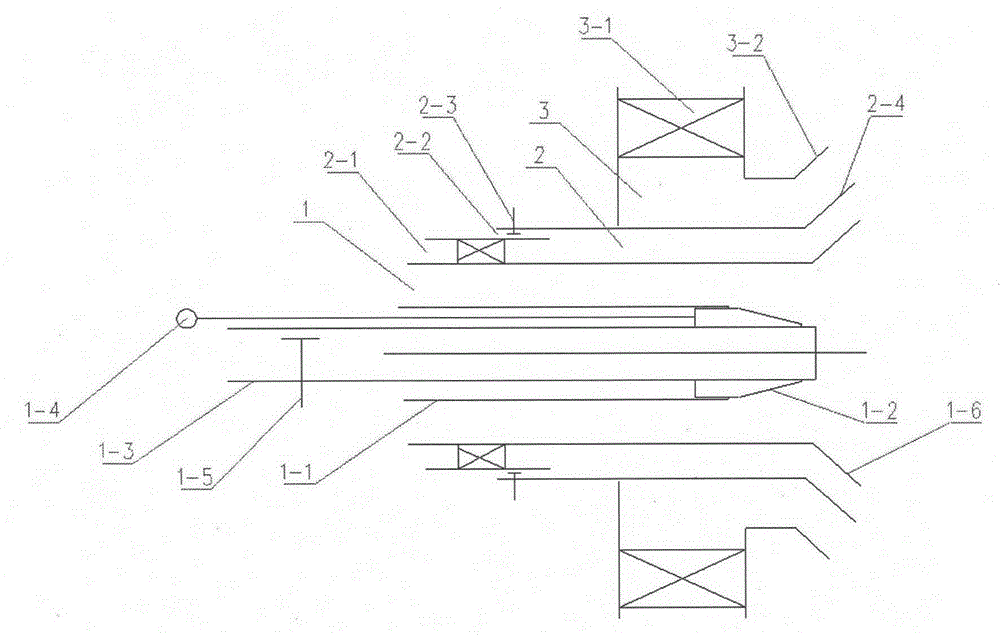

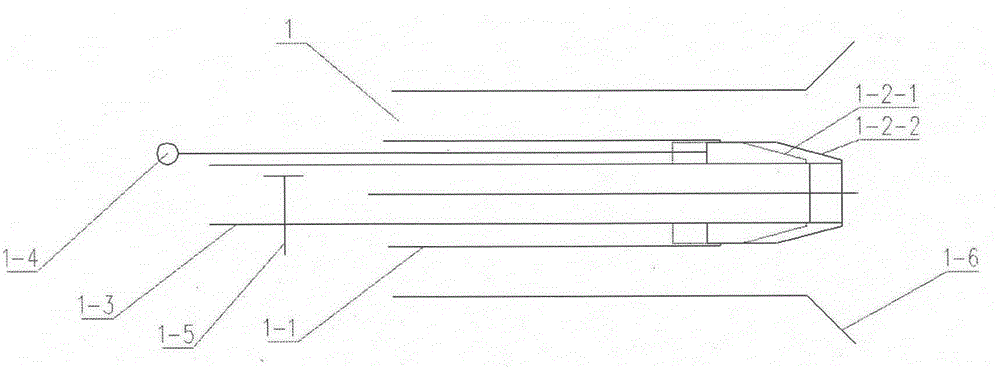

[0017] refer to figure 1 , The swirl pulverized coal burner provided by the present invention includes a primary air passage 1, an axial swirling inner secondary air passage 2 and an outermost tangential or axial swirling outer secondary air passage 3. The inner secondary air channel 2 and the outer secondary air channel 3 are located in the same large air box for air distribution. A central air cylinder structure is arranged in the center of the primary air passage 1, and the outlet of the primary air passage 1 expands to form a tapered sleeve 1-6.

[0018] combine figure 2 , the center air cylinder structure consists of a central outer cylinder 1-1, a central inner cylinder 1-3, a conical cylinder 1-2 located at the front end of the central outer cylinder 1-1, and a pull rod 1-2 for moving and adjusting the conical cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com