Device and method for determination of oil gas minimum miscibility pressure through magnetic resonance imaging technology

A technology of magnetic resonance imaging and miscible pressure, which is applied to measurement devices, fluid pressure measurement, specific gravity measurement, etc., can solve the problems of inconsistent judgment standards for miscibility, large errors, and time-consuming, and achieve the effect of visualization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

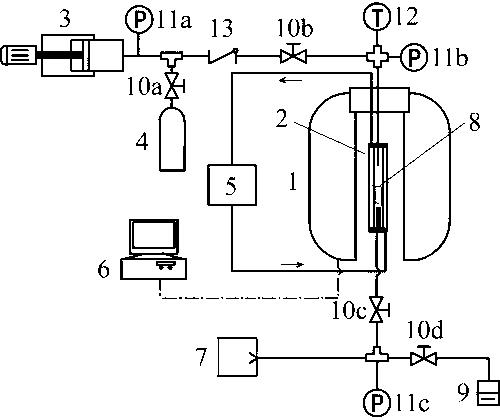

Method used

Image

Examples

Embodiment

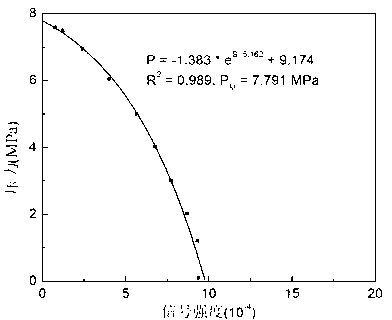

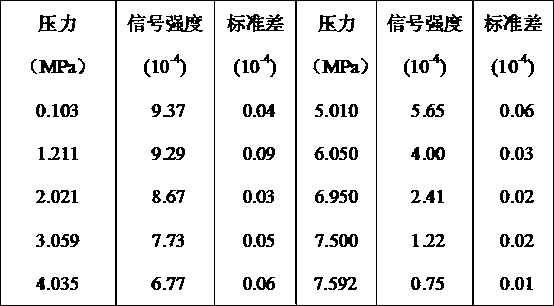

[0031] At 37.8°C, choose CO 2 / n-decane system to do the minimum miscible pressure experiment. Put 0.5ml of n-decane in a flat-bottomed test tube, place it in a high-pressure container, and obtain the signal intensities of the proton density maps of the oil phase under different pressures according to the first and second steps above, as shown in the table below. exist figure 2 In , the data points are fitted to obtain an exponential relationship curve between signal intensity and pressure. The intersection point of the curve and the pressure axis corresponds to the pressure value, which is the CO 2 The minimum miscible pressure with n-decane at 37.8°C.

[0032]

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com