Pretreatment method used for effectively extracting volatile organic compound

An organic compound and volatile technology, which is applied in the field of pretreatment of sample determination, can solve the problems of unsuitable long extraction time, difficult high temperature extraction, small extraction droplets, etc., so as to reduce sample dosage and extraction time, and increase surface gas-liquid contact The effect of low area and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

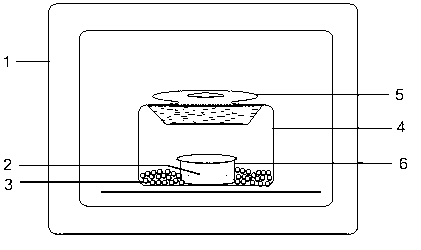

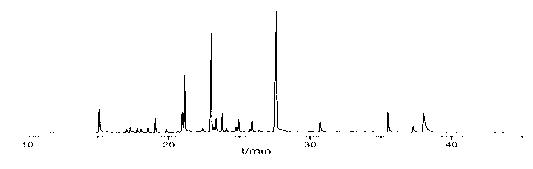

[0033] Such as figure 2 As shown in -6, in this example Atractylodes Rhizome is used as a sample, and polyethylene glycol (PEG) is used as a high boiling point solvent. Weigh Atractylodes macrocephala sample (120 mesh) and place it around the inner wall of a flat weighing bottle, measure 1 mL PEG into a small cylindrical cup and place it in the center of the weighing bottle, close the bottle cap tightly, put it into an incubator for extraction, and then use 1 mL reverse The extractant n-hexane back-extracts the analytes in the solvent cup, oscillates and mixes evenly, and then stands still. After the layers are separated, absorb the upper n-hexane layer and inject it into GC-MS for analysis. Chromatographic conditions: HP-5MS column (30 m×25 mm×0.25 μm); carrier gas: high-purity helium (99.999%), flow rate: 0.8 mL min -1 ;Injection port temperature: 250°C; -1 Rise to 160°C, hold for 3 min, and then at 8°C·min -1 Rise to 250°C and keep for 5 min; injection volume: 1 μL. Ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com