Method for judging ending point of sweet corn blanching with content of hexanal

A discrimination method, sweet corn technology, applied in the field of judging the end point of sweet corn blanching, can solve the problems of publication, lack of test data, and lack of establishment of the corresponding relationship between lipoxygenase activity and blanching end point, so as to improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] 1. Experimental instruments and reagents

[0027] 1) Experimental equipment

[0028] Agilent 7890 GC-8963 MS coupled instrument (Agilent, USA)

[0029] Heating magnetic stirrer (PC-420, Beijing Kanglin Technology Co., Ltd.)

[0030] CAR / PDMS / DVB extraction head (Supelco, USA)

[0031] 2) Experimental reagents

[0032] Hexanal standard (≥98%, Sigma, USA)

[0033] Chromatographically pure methanol (American Tiandi Company)

[0034] C 6 -C 20 Series of n-paraffin standard products (Sigma, USA)

[0035] 2. Experimental design

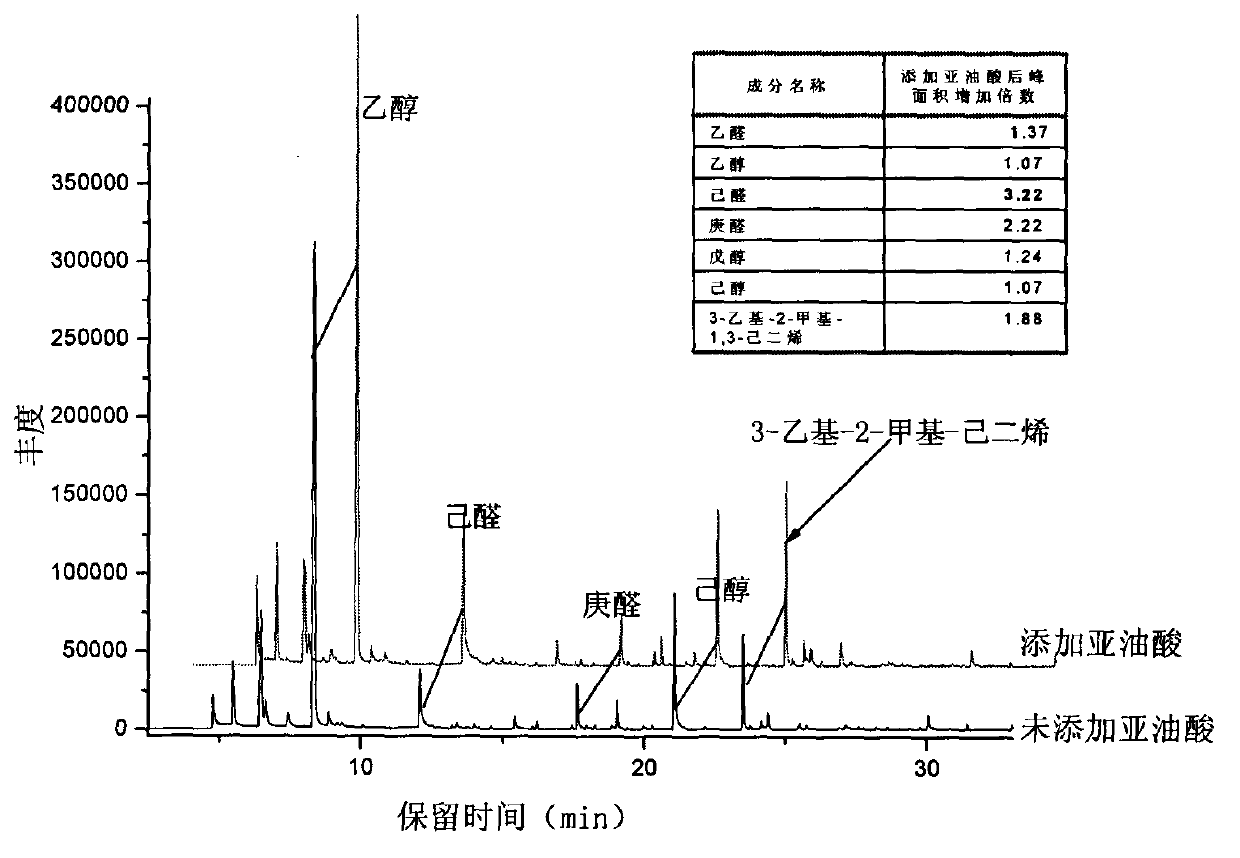

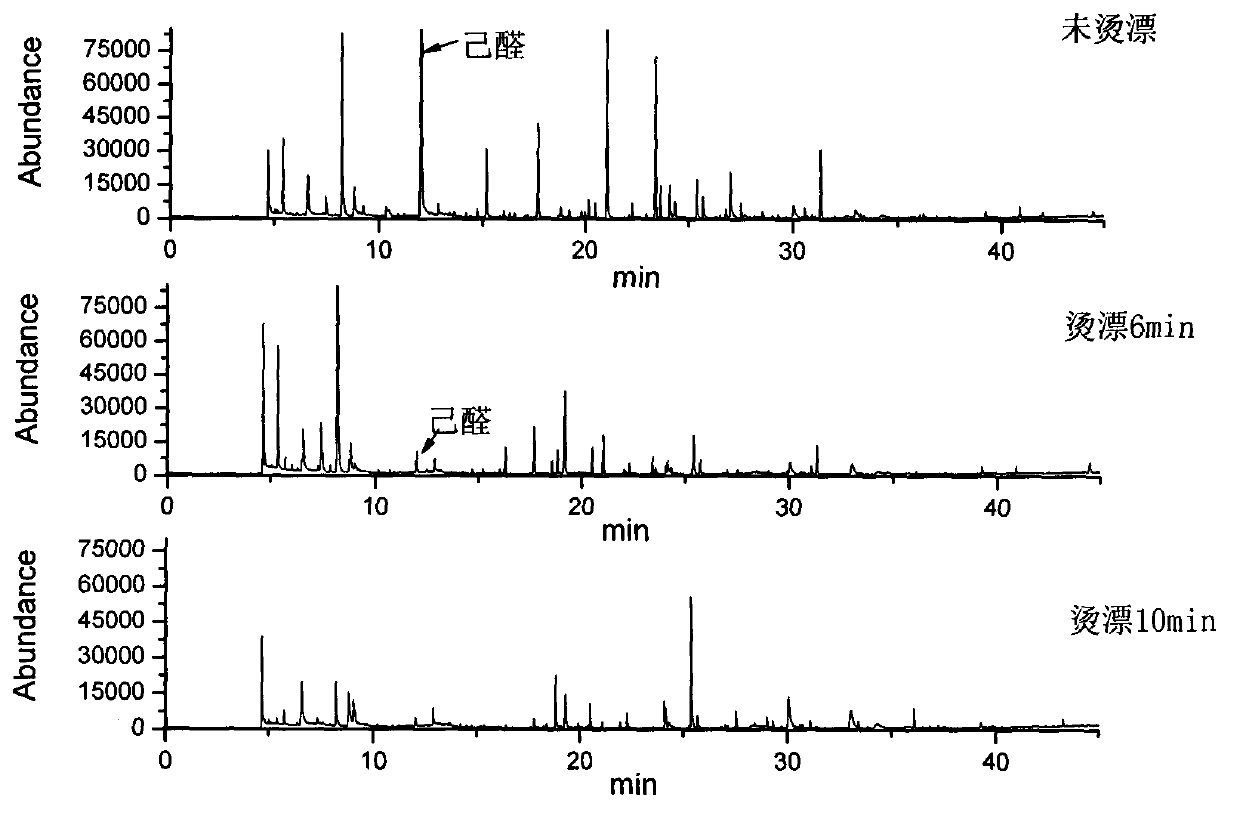

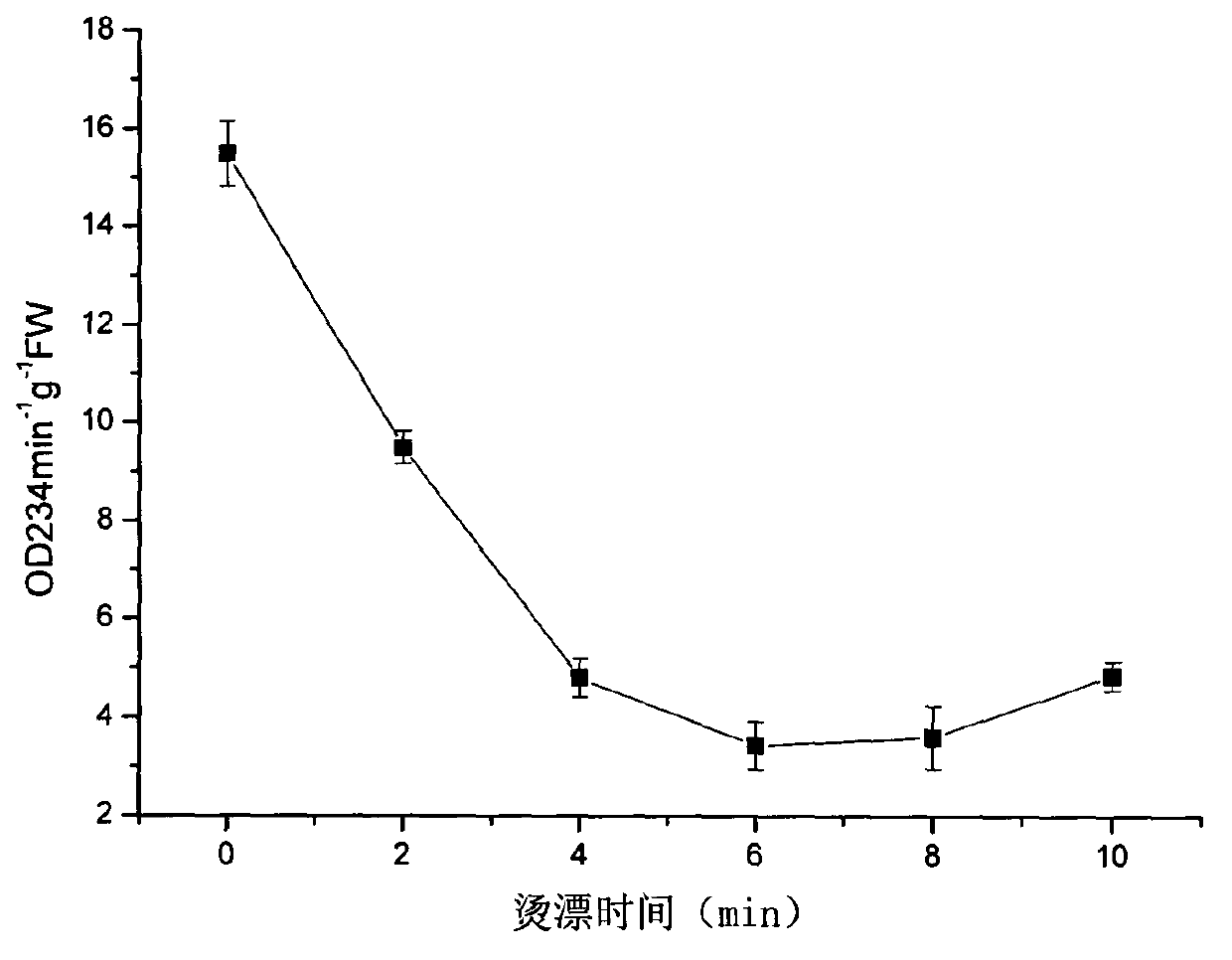

[0036] In this example, the method of homogenizing corn and buffer solution is used to fully contact and react the enzyme with the substrate;

[0037] Using the purchased hexanal reference sample, combined with the calculation of the retention index and the Agilent 7890GC-8963MS coupled instrument, the detected hexanal was qualitatively analyzed;

[0038] Establish a standard curve for the determination of hexanal for quantitative analysis;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com