Semiconductor etching device and etching method for semiconductor structure

An etching device and semiconductor technology, applied in the manufacture of semiconductor/solid-state devices, discharge tubes, electrical components, etc., can solve the problems of affecting the electrical properties of the semiconductor structure, affecting the bonding force, filling of the notch 1, etc., so as to improve the lithography accuracy and The effect of sidewall topography, avoiding systematic errors, and saving process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

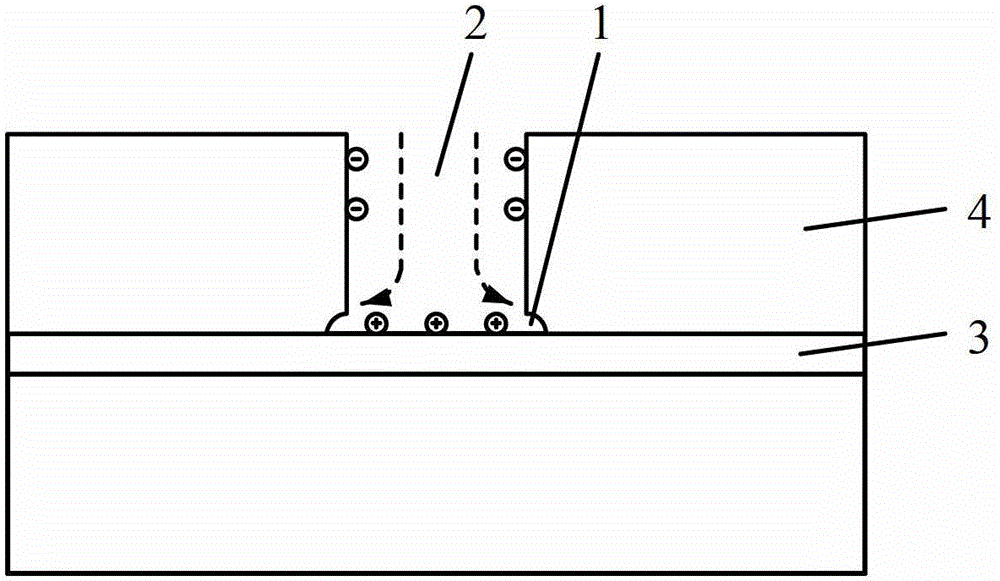

[0030] The inventors have found that in the existing multi-step etching process, the bias power source used to generate the bias voltage usually generates a continuous radio frequency signal, and uses the continuous radio frequency signal to generate continuous bias power, so that the to-be-etched The substrate surface has a bias voltage. When the plasma of the reactive gas reaches the surface of the substrate to be etched, please refer to figure 1 , due to the different angular distributions of positive ions and electrons in the plasma, positively charged positive ions tend to gather to the bottom of the structure to be etched, while negatively charged electrons tend to gather to the structure to be etched the top of. And because most of the existing etching barrier layers are insulating materials, when the surface of the etching barrier layer is etched, the positive ions gathered on the surface of the exposed etching barrier layer cannot be guided away, so that the positive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com