Reverse conducting type insulated gate bipolar transistor without snapback effect

A bipolar transistor, reverse conduction technology, applied in the field of semiconductor power devices, can solve problems such as increasing the complexity of circuit design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

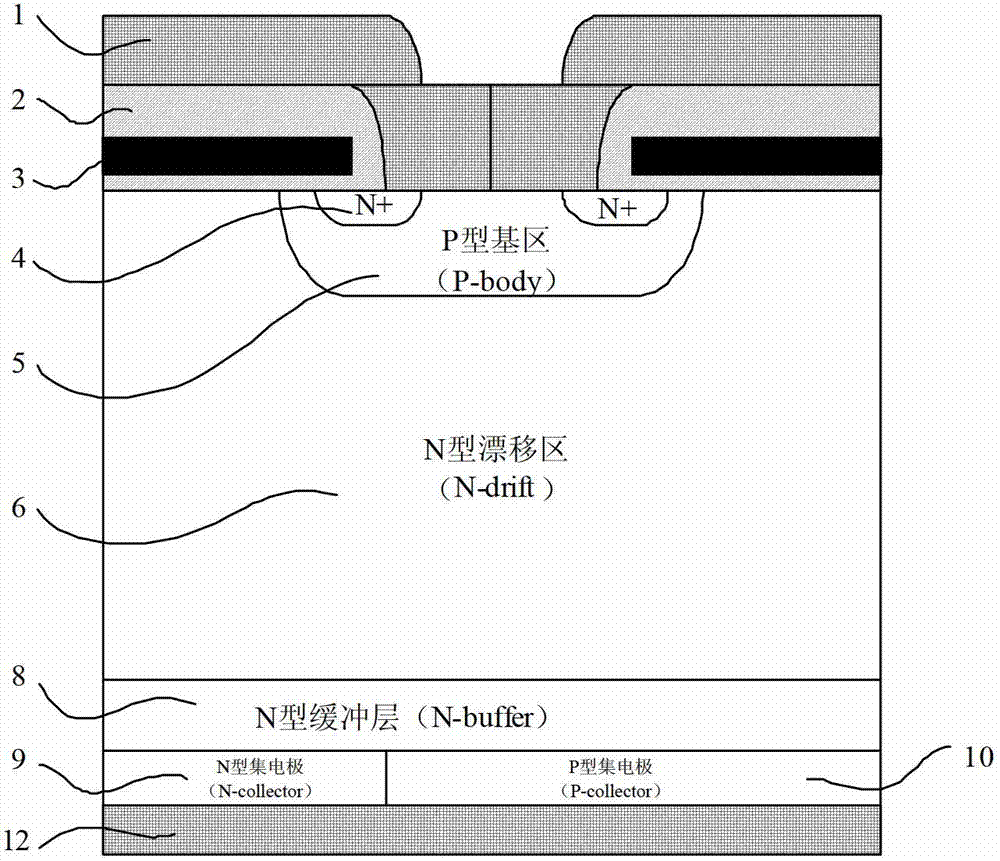

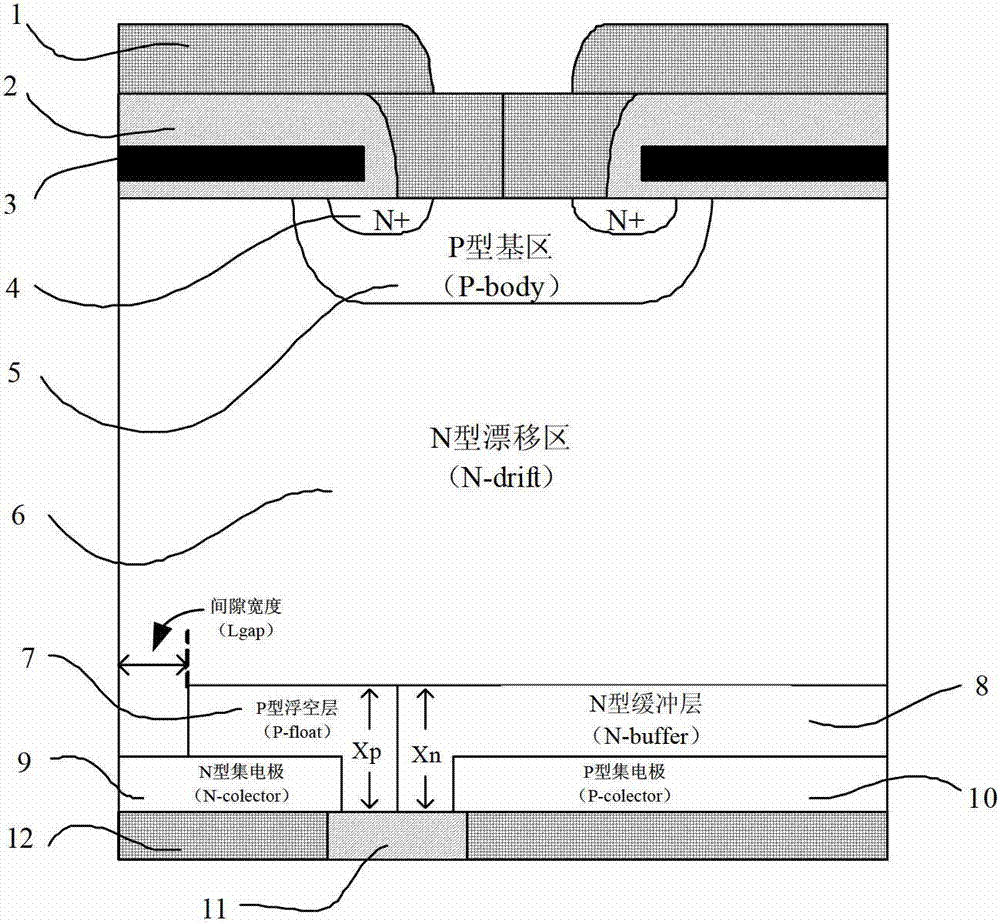

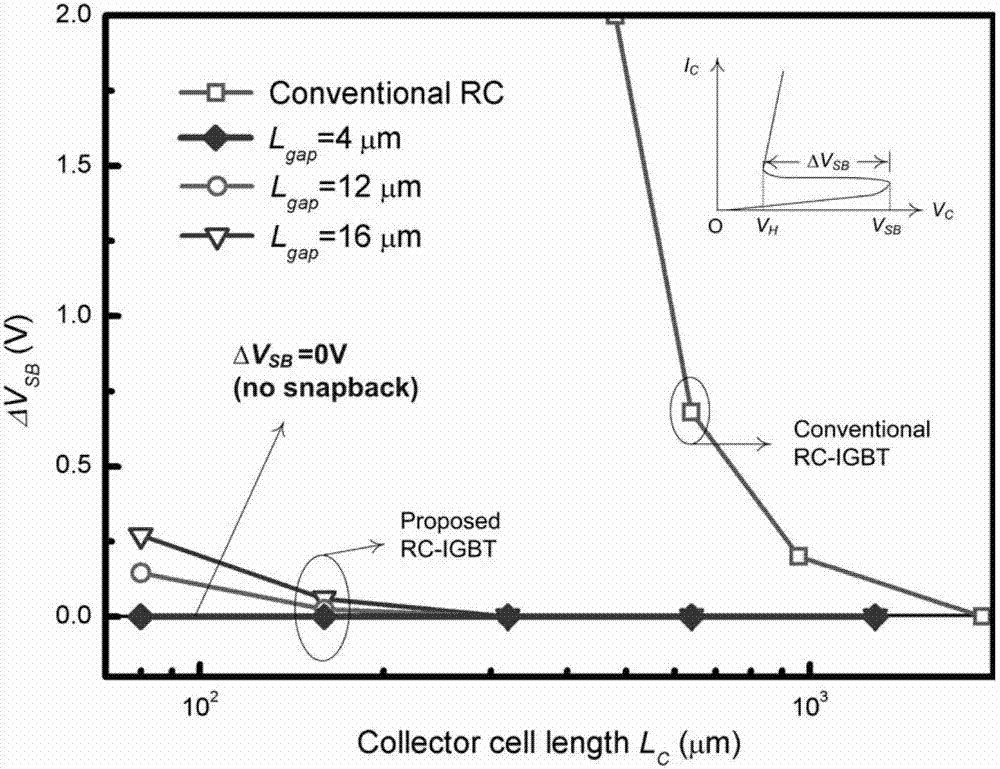

[0027] A reverse conducting insulated gate bipolar transistor without snapback effect, its structure is as follows figure 2 As shown, it includes metallized emitter 1, field oxide layer 2, polysilicon gate electrode 3, gate oxide layer, N+ source region 4, P body region 5, N- drift region 6, N buffer layer 8, N collector region 9 , P collector region 10 and metallized collector 12; P body region 5 is located on top of N-drift region 6, N+ source region 4 is located in P body region 5, and gate oxide layer is located in N+ source region 4, P body region 5 and The surface of the N-drift region 6, the polysilicon gate electrode 3 is located on the surface of the gate oxide layer, the metallized emitter 1 covers the remaining surfaces of the N+ source region 4 and the P body region 5, and the gap between the metallized emitter 1 and the polysilicon gate electrode 3 is Field oxide layer 2. The lower surface of the N-drift region 6 has a P floating region 7 and an N buffer layer 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com