Fuel cell bipolar plate for proton exchange membrane and rolling method

A proton exchange membrane and fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of difficult large-scale application, complicated process, and long time consumption, and achieve the effect of less equipment, simple process, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

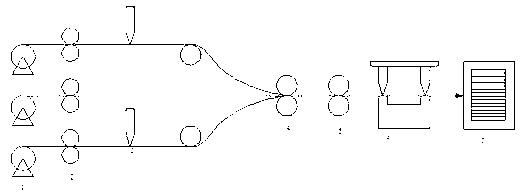

[0033] A fuel cell bipolar plate rolling processing method for proton exchange membranes, which is made of a three-layer stainless steel foil strip through laser engraving and hot rolling; the steps are as follows: 1) Uncoiler feeding: three The uncoilers supply three layers of horizontal stainless steel foil strips, and the feeding speed of uncoiler 1 must be consistent; the thickness of the stainless steel foil strips supplied by each uncoiler 1 is determined according to the structural design requirements of the bipolar plate, and the thickness of the outer stainless steel foil strips The depth of the flow channel of the flow field finally formed on the bipolar plate is determined by the hot rolling process, and the total thickness of the three-layer stainless steel foil strip and the hot rolling process determine the thickness of the final bipolar plate;

[0034] 2) Preliminary positioning of the foil strip: the three-layer stainless steel foil strip is initially positioned...

Embodiment 2

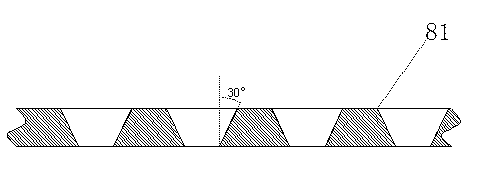

[0043] Present embodiment is except following feature, and other is all identical with embodiment 1: as Image 6 As shown, the flow field of the fuel cell bipolar plate selected for the proton exchange membrane is an interdigitated flow field, which can force the reactant gas to flow through the diffusion layer of the electrode, enhance the mass transfer capacity of the diffusion layer, and at the same time The water is drained in time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com